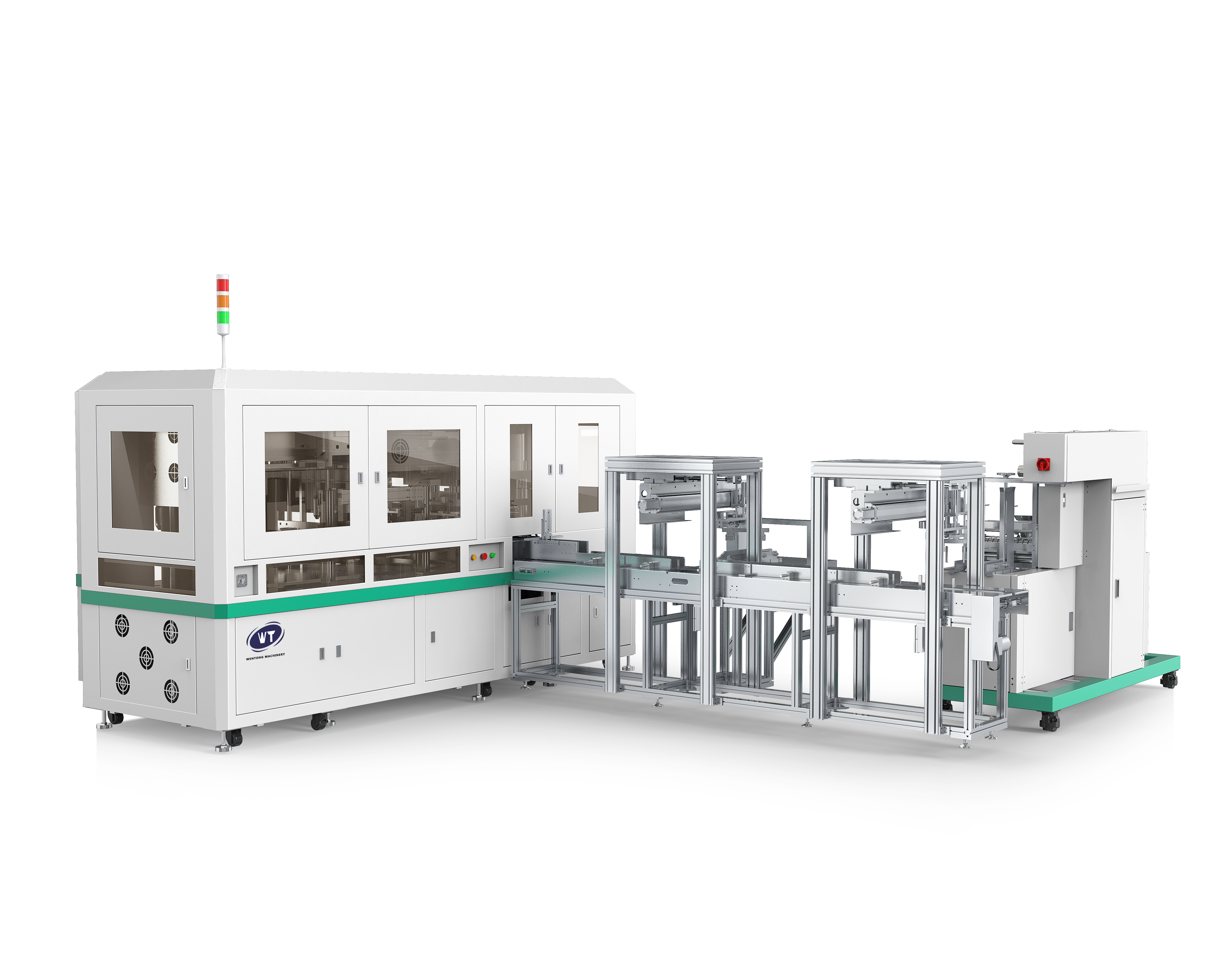

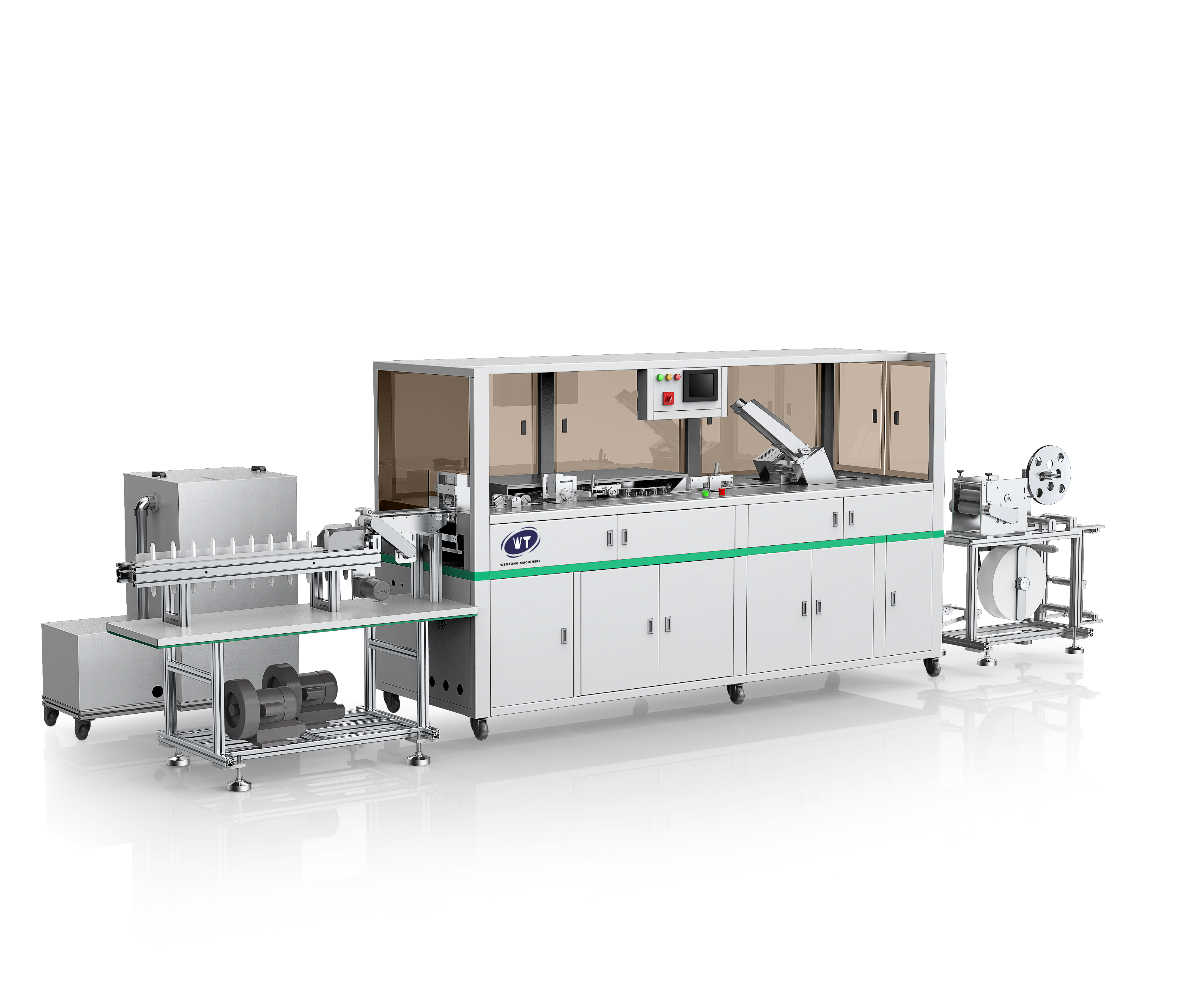

The book shape card machine from Shenzhen Wentong Machinery is a specialized solution for producing card products with a book-like structure, such as mini photo albums, promotional leaflets, and interactive greeting cards. This machine combines folding, creasing, and binding functions to create card products with multiple pages, offering a unique alternative to traditional single-sheet cards. The book shape card machine features a precision creasing system that creates clean, uniform folds, even for thick cardstock, while the binding unit can be configured for different styles, including saddle stitching or glue binding. Wentong’s design emphasizes flexibility, with adjustable guides and dies to accommodate various book sizes, from small 4x6-inch formats to larger 8x10-inch designs. The machine’s intelligent control system ensures that each page is accurately positioned, preventing misalignments that can affect the final product’s appearance. A key advantage of this machine is its ability to integrate special features, such as die-cut windows or pop-up elements, adding a tactile and visual appeal to book shape cards. With a production capacity of up to 200 books per hour, the machine balances efficiency with craftsmanship, making it ideal for both mass production and customized orders. Wentong’s book shape card machine is built with heavy-duty steel frames to withstand continuous operation, ensuring long-term reliability for manufacturers.