What We Do

Years of

Experience

Who We Are

Wentong | Innovating Smart Card & Post-Press Solutions Since 2008 Founded in 2008 and backed by 20+ years of industry expertise, Wentong specializes in the design and manufacturing of high-performance smart card machinery and post-press equipment. We empower global clients to streamline production processes for children’s books, board books, paper cards, and plastic cards, delivering solutions that evolve with market demands.Smart Card Systems: Die-cutting, collating, punching, and SIM card production machinesBookbinding Solutions: Board book mounting/gluing machines, automated packaging systems

Precision Technologies: Ultrasonic welding systems, magnetic tape applicators, sheet cleaning machines

Serving diverse sectors including card manufacturing, printing & packaging, educational publishing, and paper product engineering.

Relentlessly upgrading technologies and services to ensure quality, efficiency, and scalability for clients worldwide.

Exporting countries

Customized Solutions

Equipment accuracy

Equipment life

machine is customizable to meet specific needs, with optional add-ons like bundling, sorting, or cellophane wrapping. Tailored designs for new systems are also available upon request.

15-Year OEM/ODM Expertise

48hr Provide complete equipment solutions within

30% Cost Reduction Guarantee

99.8% after-sales satisfaction

Application Scenario

We have 15 years of design and innovation experience in smart cards, soft magnetic cards, card packaging, and post-printing products. Related processes include punching, die-cutting, bundling packaging, cellophane packaging, card individual packaging, and magnetic stripe laying, and we can produce most card products.

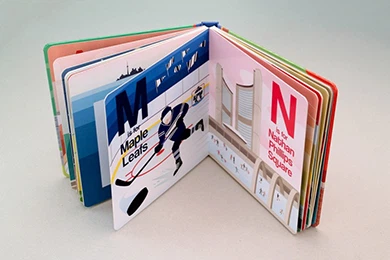

Increasingly popular with children and parents, you may find that more and more children’s books with various shapes are constantly being published.

In response to high demand for customized playing cards, Wentong dedicated to satisfying the expectations of our customers by developing and manufacturing high precision playing card production lines.

Wentong offers complete SIM card and smart card production lines including card punching machine, card milling machine, card chip implanting machine, card testing machine and card packaging machine.

Since the establishment of the company, it has cooperated with more than 1,500 customers in more than 50 countries around the world and provided professional solutions.

We create powerful and effective high-precision solutions. As a top manufacturer of industrial cutting equipment, including die cutters, tape laying machines, and card packaging machines, Wentong has provided customers with tailor-made solutions for over 20 years. Our flexibility, reliability, experience, and capabilities ensure that customers' requirements are transformed into high-quality machines exceeding expectations.

The PVC card punching machine is the most important tool for making cards, which improves technology and completely solves this problem. By combining visual correction with progressive feed, modern high-precision punching machines have completely changed the way stamping is done.

Mar, 07, 2026

The PVC card punching machine, also known as the die-cutting machine, is the most important part of making PVC cards because it affects the quality of the finished product. Layering is a common technical issue faced by many printing and business card factories

Mar, 06, 2026

PVC card printing machines are now the most important tool for making game cards, gaming cards, anime cards, and other smart cards. This is because the printing and packaging industry is shifting towards a "short, flat, fast" model.

Mar, 05, 2026