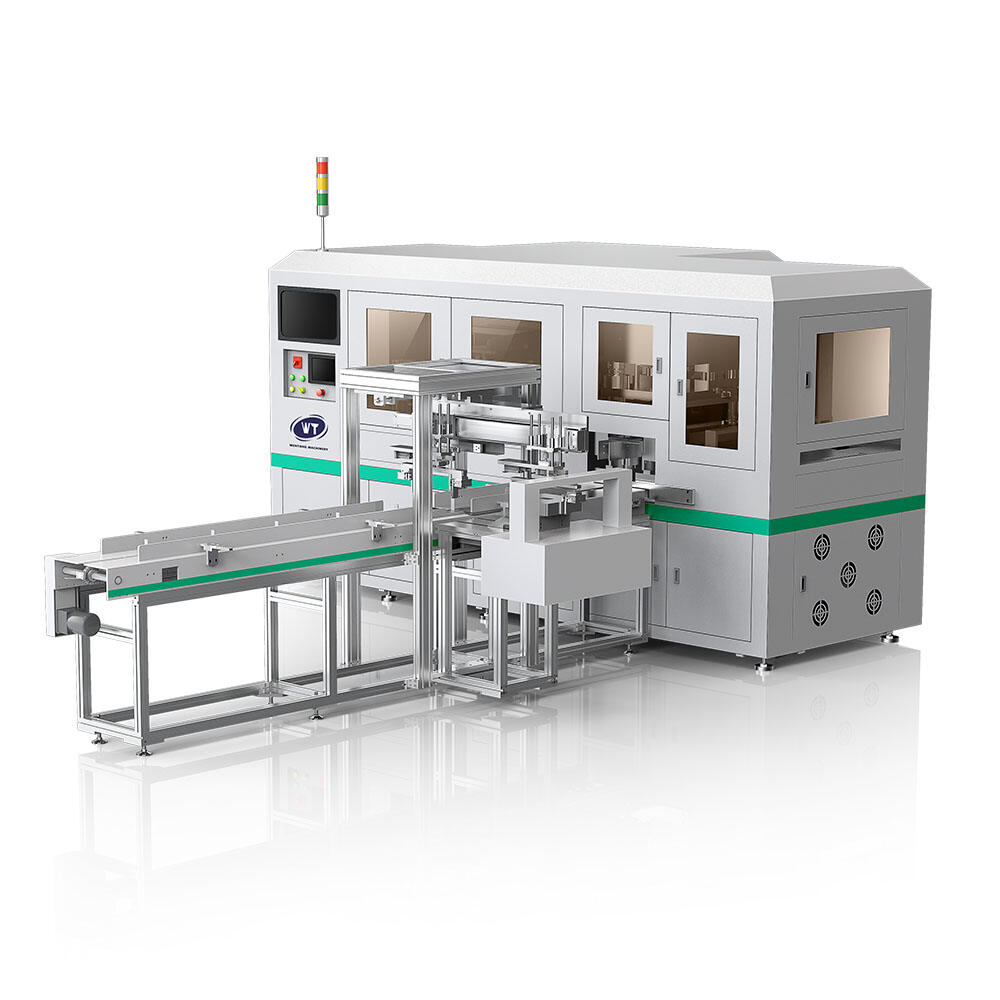

PVC card die-cutting machine is a high-precision automatic production equipment specially made for the card making industry today. It perfectly combines precision machinery, intelligent servo control and automatic sorting technology.

The PVC card die-cutting machine is high-precision automatic production equipment specially made for the card-making industry today. It perfectly combines precision machinery, intelligent servo control and automatic sorting technology. It is widely used in the mass and personalised production of special cards such as smart cards, game cards, bank cards, and membership cards. The equipment is an innovative product of Shenzhen, the global manufacturing centre. Strictly following international standards, it aims to provide global overseas market customers with efficient, stable and flexible productivity tools to help enterprises cope with increasingly severe market challenges and quality requirements.

The core structure of the equipment adopts a high-strength cast iron frame and is treated with ageing to ensure long-term stable operation. The main cutter adopts imported special tool steel, which is vacuum heat treated and plated with DLC diamond-like material. High hardness (HRC58-62), can be punched more than 3 million times. The card edge adopts a unique precision grinding process (roughness Ra≤0.2), and the edge is smooth without burrs. Meet the factory packaging standards.

The equipment works in a very flexible way. The quick mould change system (mould change time ≤ 15 minutes) can not only quickly produce a large number of different types of PVC cards but also quickly switch to stamping book covers or processing industrial filter paper. The modular design, turntable station, and pre-installation of multiple moulds can realise continuous production of products of different specifications. This also makes the overall equipment utilisation rate reach a new high.

The device can be built in a high-precision hot stamping unit, making high-end cards more valuable. The unit uses a visual positioning system (±0.1 mm accuracy) and a precise temperature control system (±2℃ accuracy) to ensure that the die-cutting and hot stamping processes are completed perfectly in one go. This makes it ideal for items such as bank cards and membership cards where patterns need to be placed in specific locations.

The drive system adopts a 7.5 kW servo motor with full closed-loop control, and the peak power can reach 11 kW. Linear encoder feedback, repeated positioning accuracy ≤0.02 mm. The system has a variety of optimised stamping modes, including standard (40-80 times/min) and high-speed (up to 100 times/min). The goal is to maximise production efficiency while ensuring quality. It saves more than 45% of energy compared with traditional hydraulic equipment.

Using machine vision, the integrated intelligent sorting system can identify different information such as the colour, pattern, text, and QR code of the card. The sorting accuracy rate is 99.8%. Two main collection methods are available: sequential collection (maintaining the order of output) and classified collection (sending materials to up to 12 separate collection slots). It can sort 40 cards per minute.

We offer a wide range of customisation services, from equipment setup and mould design to production line integration. The control system adopts an open architecture and can communicate with MES and ERP systems. The equipment can change pressure, speed, temperature and other settings to obtain the best processing effect for special materials such as metal composites and bio-based materials.

The material is cut cleanly and neatly due to the micron-level gap control (adjustment accuracy of 0.01 mm) and optimised blanking curve. There are many different material parameter combinations in the system. It can also remember and learn the best settings for new materials. It can be used with many different substrates, such as PVC, PET and ABS, as long as the thickness is between 0.2 and 2.0 mm and the edges are smooth.

Flexible finished product collection methods to meet different production needs:

The quick mould change and parameter preset functions reduce the minimum economic production batch to less than 1,000 sheets. The equipment can store up to 50 sets of die parameters, which solves the efficiency and cost problems of traditional equipment in dealing with personalised and short-term promotional orders.

The automatic alignment system, graphical operation interface and intelligent diagnosis function make the operation and maintenance of the equipment more convenient. Customers have reported that the training time for new employees has been reduced from 2-3 months for traditional equipment to 2-3 weeks.

The built-in data acquisition system monitors the output, quality, equipment status, and energy consumption in real time. The data can be sent to the management platform to help decision-making. The perfect production parameter and quality record traceability system is especially suitable for the production of high-security products such as bank cards and ID cards.

The electrical system can adapt to the voltage standards of multiple countries (110V-480V), and the safety standards meet CE, UL and CCC standards. The equipment is designed to be energy-saving and environmentally friendly. Intelligent nesting, with a material utilisation rate of up to 92% or more. It can also be changed to use environmentally friendly recycled PVC and bio-based materials, which helps customers achieve their green production goals.

The interface layout is clear, and the equipment is equipped with a 15-inch industrial-grade touch screen. It can be used in fully automatic, semi-automatic, and manual modes. The "Wizard" function makes it easier to set complex parameters. You can save these settings and call them "recipes" to ensure that production is always the same and simple.

Preventive maintenance design with lifetime tips for the most important components. The centralised automatic lubrication system makes daily maintenance easier. Modular and standardised design, easy to get spare parts, and low long-term operating costs. The self-diagnostic system can monitor more than 100 items and provide repairs.

Built-in safety door lock, emergency stop button, two-hand start device. The software adopts multi-level operation authority management. The electric cabinet meets the IP54 protection level, and a dust collection system can be added to ensure personnel safety and a clean production area.

We provide multilingual training materials (such as documents and videos) and user interfaces. We have service centres or partners in major market regions around the world to ensure that spare parts and technical support are provided quickly and that customers do not lose too much time when problems occur.

When making chip cards and dual-interface cards, the equipment can control the cutting accuracy of the chip window within ±0.1 mm and ensure the integrity of special structures such as antennas. Actual cases show that after a manufacturer used the equipment, the overall defect rate of the product dropped from 0.8% to 0.15%.

With its high pattern registration accuracy (error <0.15 mm) and fast mould change speed, it can cope with a wide range of designs and large batches. The sorting collection function automatically sorts by rarity, making packaging easier and helping customers accelerate time to market.

The equipment can run for a long time without failure (MTBF > 2000 hours) and can handle card materials with complex structures, such as metal layers and transparent windows. The application's real-world use has helped manufacturers reduce energy use by 45%, overall production costs by 18%, and production efficiency by 60%.

The high-speed production capacity meets the needs of large promotional orders and can be linked with digital printing to automatically produce variable data cards. Its excellent process adaptability is reflected in the fields of book covers, industrial filter paper, etc.

Power supply |

AC 380V/50 HZ |

Sheet format |

Max. (L*W) 1000*700MM Min. (L*W) 550*450MM |

Total power |

10KW |

Control |

PLC control + Servo system |

Air source |

6 kg/cm2 |

Operators needed |

1 |

Air consumption |

Approx. 80L/min |

Dimension |

L2800*W1750*H1850MM |

Punching pressure |

2T-6T |

Drive |

Servo system |

Weight |

Approx. 2000KG |

Punched card size |

Max. 140*140MM Min. 54*54MM |

Punching accuracy |

±0.05mm |

Productivity |

1200 Sheets/H |

Applicable card materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

PVC card die-cutting machines are the best choice for card manufacturers around the world due to their precise cutting technology, high degree of automation and multiple customisation capabilities. It can not only help enterprises improve efficiency and produce better products but also is a key link for enterprises to build digital and flexible production capabilities. We hope to become your trusted partner by continuously launching new technologies and providing the best global services. Together, we can raise the standards of the card manufacturing industry.