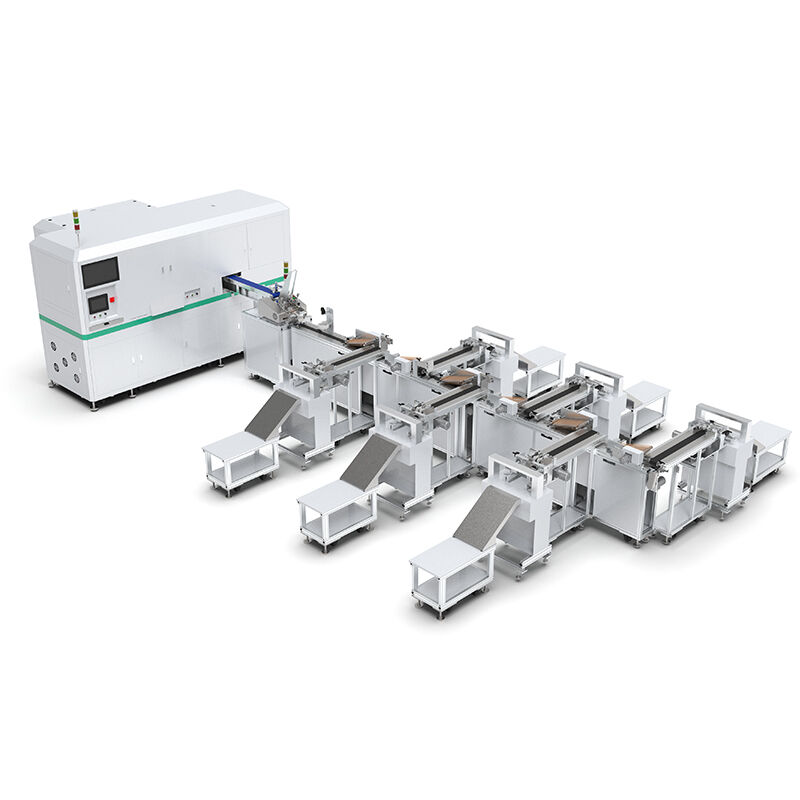

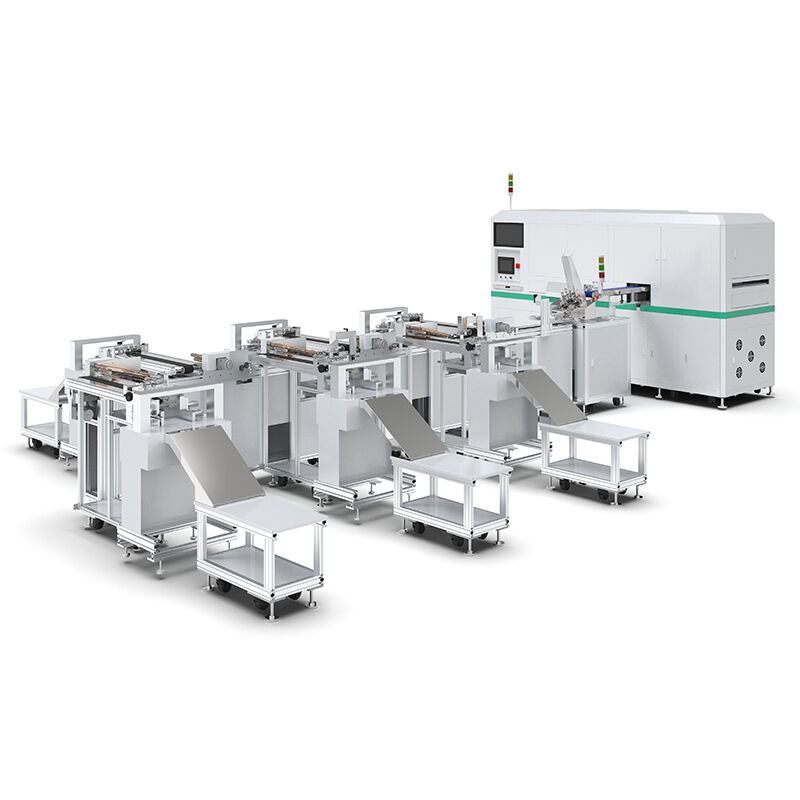

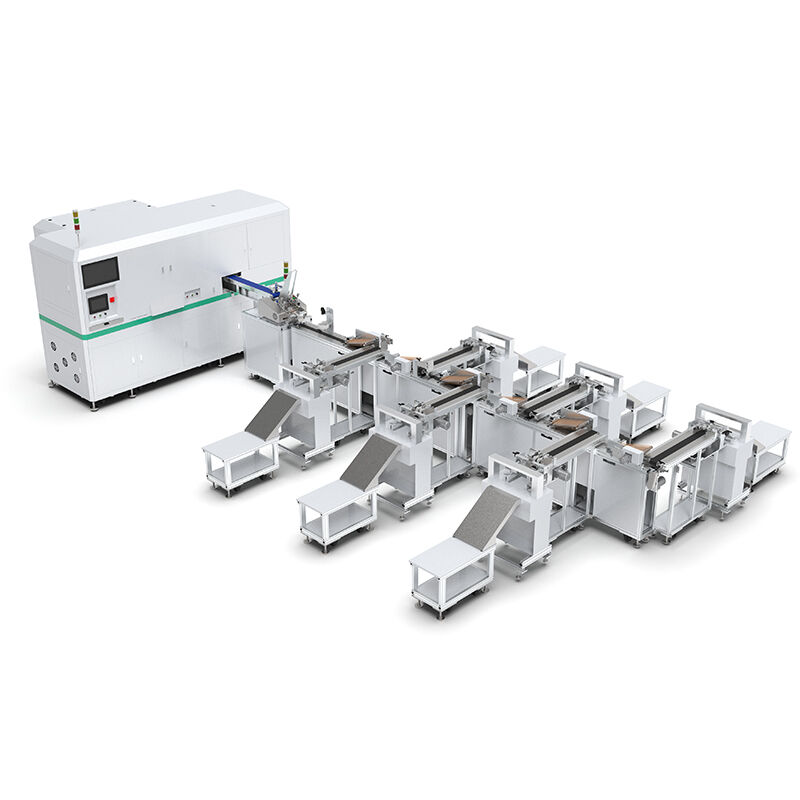

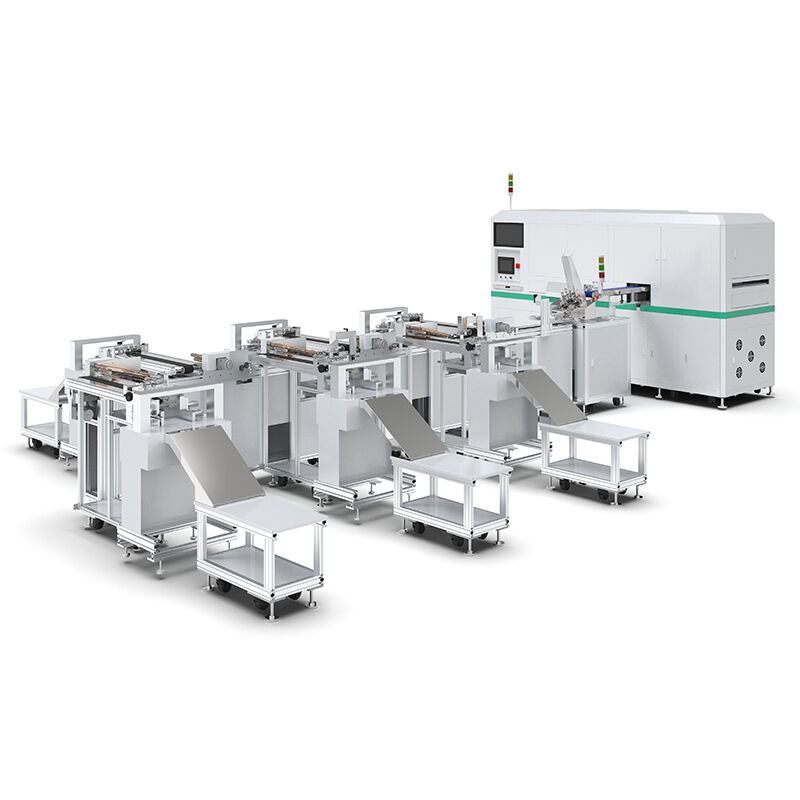

In the field of business card printing, the demand for post-processing speed, accuracy, and flexibility has been on the rise. This includes everything from high-end smart cards and credit cards to gaming cards and customized membership cards. The market no longer needs old-fashioned punch presses that can only do one thing. They need machines that can do many different things, do small batch production, are very accurate, and can classify themselves. To address this issue in the industry, we are from Shenzhen, China, and have created and released a fully automated machine using cutting-edge core technology for sorting and punching cards. We do this because we have a deep understanding of the global market and have been manufacturing precision tools for a long time. This machine is not just a high-performance card punching machine; it is also an intelligent production unit that can punch holes and sort. Its goal is to provide fast, accurate, and flexible best solutions for business card manufacturers around the world.

1. The core functions and production application scope of the fully automatic classification, sorting, and card punching machine

The main idea behind this fully automatic sorting and punching machine is to perfectly combine intelligent processes with precise punching. The only thing traditional punching machines can do is stamping and separating. This new machine can accomplish all of these and even more, such as sorting, counting, and stacking. It can make rolls or sheets into finished products at once.

1. Wide range of production applications:

This device is very compatible and can use many different card shapes and materials. People often use it:

-

Payment and identity recognition: PVC, ABS, or PETG materials for bank cards, credit cards, membership cards, access cards, and SIM cards.

-

Entertainment and Collectibles: Cards used for entertainment and collectibles include poker cards, collectible cards (such as Game King and Wanzhi cards), anime collectible cards, and sports cards.

-

Intelligent and industrial categories: Examples of intelligent and industrial categories include smart cards (IC cards) with or without contact, RFID tag cards, nameplates, and tags of different thicknesses.

-

Special stamping applications: It can also stamp certain materials, such as hardcover book covers, high-end filter paper, leather decorative panels, etc., with high precision and pressure control. You can achieve this by replacing the mold, making it a 'multi-purpose machine.'

2. A new feature that automatically sorts and classifies things:

This is the most famous thing that sets this machine apart from other clock-in machines on the market. This device has an intelligent logic control system and high-sensitivity optical sensors, which can automatically classify and group the cut cards according to preset programs.

-

Collect in order: This is useful when it is necessary to strictly follow the output order, such as numbering cards in order or creating card collections in design order.

-

Collect by category: This device can distinguish differences between different colors, patterns, or preset identifiers, such as chip types or printed labels. Then, it can automatically send different types of cards to different assembly lines or collection slots. For example, the machine can automatically separate regular cards and flashcards mixed and punched on the same paper. This saves a lot of time and errors, which would occur if people had to do it manually.

3. A good foundation for stamping quality:

All advanced features require perfect stamping quality to work.

-

Cutting without burrs: Thanks to the high-rigidity integrated body and precise guiding mechanism, the mold is perfectly closed. The incision is smooth and flat, without burrs, wire drawing, or delamination. The texture on the edges of the card is also very good. This is because of high-quality cutting molds and unique optimized stamping curves. This meets the requirements of high-end finished products.

-

Unique texture expression: Correct pressure control keeps the card substrate strong. Even multi-layer composite cards have tight and smooth edges after stamping. This makes the product look better overall.

-

Potential for post-stamping processes such as hot stamping: The design of the equipment platform includes process interfaces, which make it easy to add hot stamping units for one-time stamping and partial hot stamping. This makes the card look more luxurious and the product more valuable.

2、 Detailed explanation of technical architecture and key parameters

The device runs well because it uses new reliable technology.

1. Power supply and control system:

-

Automated 7.5 kW servo drive system: Most of the power for this equipment comes from high-power servo motors. They give you stable, powerful, and accurate power that you can change. Servo systems are better than ordinary electric or pneumatic motors because they respond faster, are quieter, consume less energy (about 30% less), and can control speed and pressure with perfect precision. Even if the machine speed is fast (up to 60-90 times per minute, depending on the size and material of the card), it can maintain the same force and depth for each punch each time.

-

Mature dual-core control of industrial PC and PLC: The system runs stably and reliably because it uses a control scheme that has been tested for a long time in the real world. Human Machine Interface (HMI) is a touch screen that can display colors and support multiple languages. You can also easily change settings and view and export production data in real-time, such as counting, speed, and fault records.

2. Customized design and mechanical structure:

-

Ultra-high durability structure: The main frame is made of high-strength cast iron or steel plate, welded and stress relieved, and its shape does not change much during long-term heavy load use. The service life of this device is much longer than normal equipment in the industry. Ball screws and linear guides are manufactured by well-known brands around the world to ensure that the machine remains precise for extended periods of time.

We understand that different customers have different needs in terms of raw materials, finished products, and factory settings. That's why we offer complete, tailored, collaborative solutions. Our complete design includes a feeding system that automatically feeds rolls or stacked sheets, a drilling host, an automatic classification and sorting module, and personalized ways of collecting finished products, such as boxing, stacking, and connecting packaging. Customers can choose how to obtain the item. For example, they can choose to stack a stack of 100 sheets of paper or set up separate packaging lines for different types of products.

3. Precise sensing and classification technology:

By using high-resolution CCD visual inspection or precision photoelectric sensors, classification systems can identify things with an accuracy of over 99.9%.

The sorting execution mechanism is driven by an independent servo motor that moves quickly and gently to avoid scratching the cards.

3. Competitive advantage: Not only is it fast, but the overall efficiency is also higher.

When smart customers purchase production equipment, they consider total cost of ownership (TCO) and return on investment (ROI). Fully automatic sorting and card-punching machines have become very competitive in many fields:

-

Efficiency comparison: This machine combines two separate steps, reducing waiting, processing, and manual work time between steps. Compared with the old "punch press + manual sorting" method, this can increase overall production efficiency by more than 40%.

-

Comparison of labor and quality costs: When you consider the costs of labor and quality, you will find that you do not need as many skilled sorting workers. This reduces labor costs and makes management easier. On the other hand, automatic sorting almost completely eliminates the problems that may occur with manual sorting, such as item loss, missed detections, and contamination. It also makes the quality of product delivery more stable, thereby reducing the number of customer complaints and the cost of rework.

-

Flexibility comparison: The intelligent classification system of this device enables it to quickly and effectively handle various small batch production tasks. This is completely in line with the current trend of buying things specially made for you. This is different from traditional automated production lines, which can only produce one type of product at a time.

-

Technical maturity guarantee: The core servo technology, control logic, and mechanical structure we use have undergone years of testing and improvement in the market. This means that the device can be safely used in many different industrial environments around the world. This also means that maintenance costs can be reduced and spare parts are always available.

4. Successful application cases that bring value

Our equipment has been successfully used by many of the best business card manufacturers in the world.

Case 1: A European company that produces expensive game cards

-

Challenge: Creating complex card packs that include regular cards, rare flash cards, and special process cards requires very high precision and 100% accurate classification. Manual sorting has poor results and can make many mistakes.

-

Solution: Cards can be classified and punched and have a visual recognition system. The camera on the device can immediately see the special gloss or small marks on the card after punching. Then, it places the cards into three different channels and stacks them in a certain order.

-

Effect: The result is a 50% increase in production efficiency, a zero sorting error rate, a significant reduction in the time required to prepare product packaging, and a significant increase in customer satisfaction.

Case 2: A large factory in Asia that produces smart cards

-

Challenge: Simultaneously produce different types of IC cards and access cards while handling broken orders, frequent product replacements, and the need to quickly clean mixed semi-finished products inside the machine.

-

Solution: Use a device that can perform both "sequential collection" and "model classification collection" as the solution. For daily mass production, use classification mode. Use sequential collection mode during small-scale, multi-variety trial production or when switching production lines to ensure that each batch of cards is clearly different and not confused.

-

Effect: The company can now work more flexibly. Its main competitive advantage is the ability to handle fewer minimum orders, transfer inventory faster, and respond to the market faster.

This fully automatic sorting and clocking machine is not just a machine. This is the intelligent production engine we have created for the global business card printing industry, oriented towards the future. It directly brings measurable benefits to customers in terms of efficiency, quality, and cost through the use of precise cutting technology and the latest concept of automated logistics. Our Shenzhen R&D and manufacturing center is always ready to provide you with more technical details, show you how to use our products, and help you provide global services. All of these will help make your production line smarter.