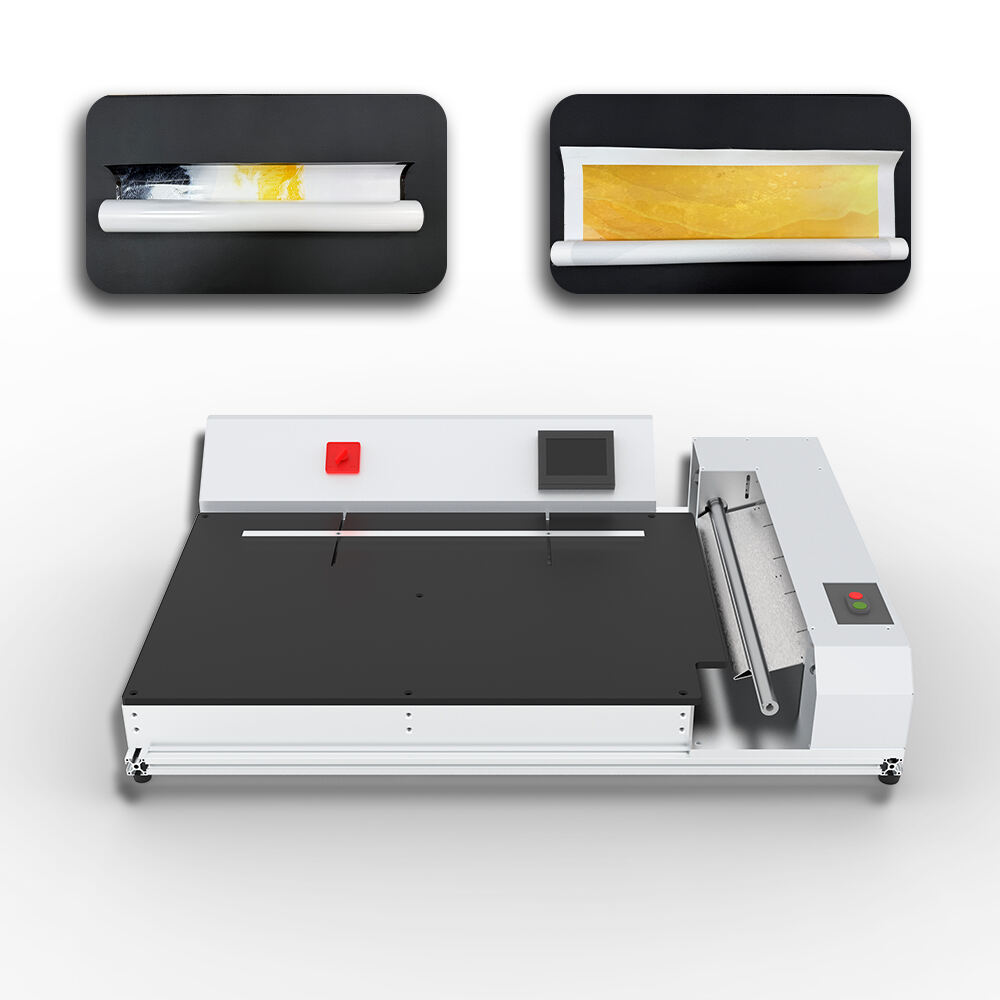

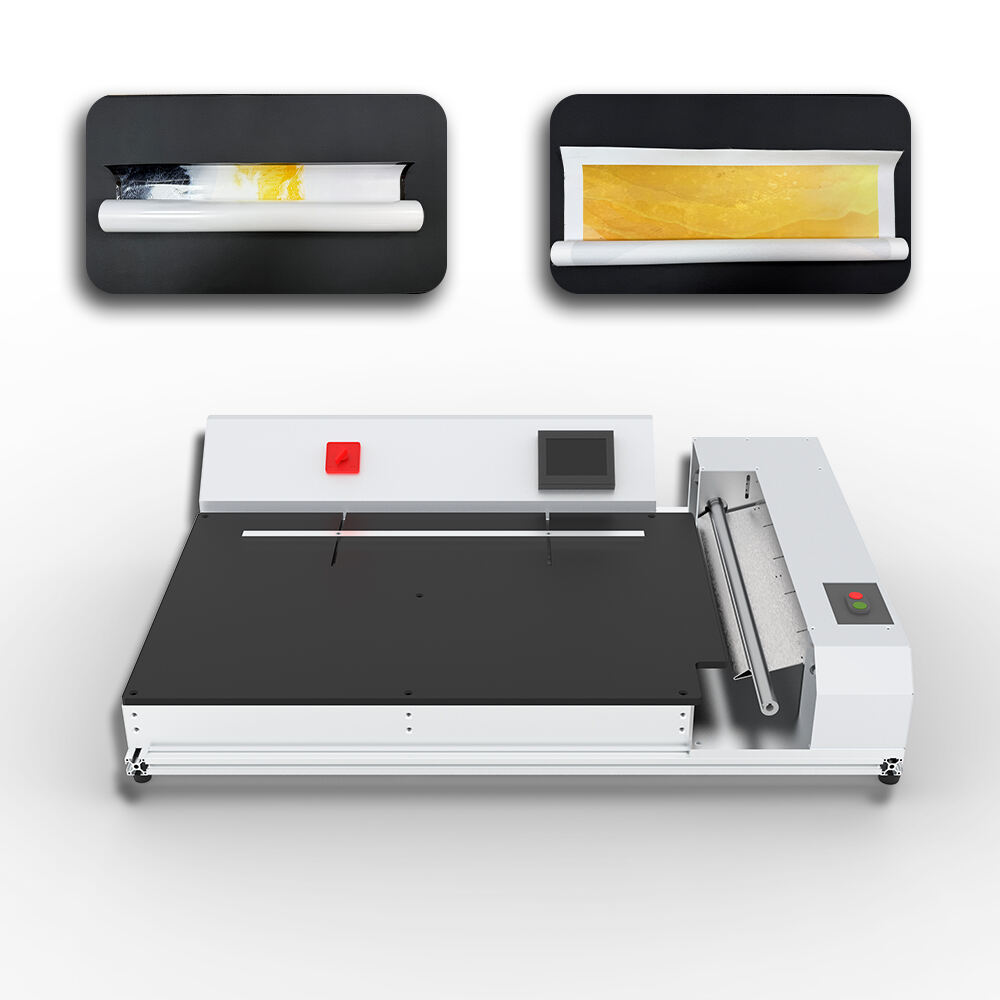

The Roll Up Machine is an advanced process that can wind one or more materials at a time. This feature is essential for the production of multi-layer learning cards,

In the global printing and packaging industry, fast production determines the delivery capacity to customers. The efficiency and quality of post-processing, in turn, restrict the delivery capacity of enterprises and weaken the competitiveness of enterprises in the market. The difficulty of winding up products such as posters and EVA materials has prompted enterprises to rethink their dependence on manual winding. Slow production speed, high labor costs, and unstable quality control have caused dissatisfaction among customers and end users.

To cope with these problems, we focus on providing the latest integrated intelligent automatic roll-up machine for overseas customers. The equipment is designed to complete the winding through automation and precise control.

The winder is carefully designed to refocus the vision of automation on the winding system:

The modular and adjustable design of the Roll Up Machine helps to achieve strong material flexibility and versatility:

One device can be used for multiple materials, saving you a lot of costs.

We believe that powerful features and ease of operation can reduce labor costs. The touch screen HMI and logical menu sequence design enable operators to be trained quickly. The parameter preset and call function enable one-key order switching.

The Roll Up Machine is an advanced process that can wind one or more materials at a time. This feature is essential for the production of multi-layer learning cards, sample books, padded posters, and other products that require winding and compounding, providing strong technical support for you to develop new product lines and market opportunities.

Core configuration: A brand servo motor, PLC control system, and precision bearing are adopted to ensure stable and reliable use for a long time.

Safety standard: Multiple protection system design, comprehensive protection of human and machine safety, in line with CE international safety specifications.

Global service: Our headquarters is located in Shenzhen, China. The perfect international logistics and service system enables us to provide global customers with remote technical support, rapid spare parts turnover, and on-site engineer services so that customers can rest assured.

With a professional toilet roll-up machine, you are not only buying a machine but also the modernization of the production plan and the improvement of production, quality, and cost efficiency. In the 21st century, with the toilet paper rewinder, you will be more price competitive.

We warmly welcome your interest in these innovative products that may change your production mode. For specific customized quotations