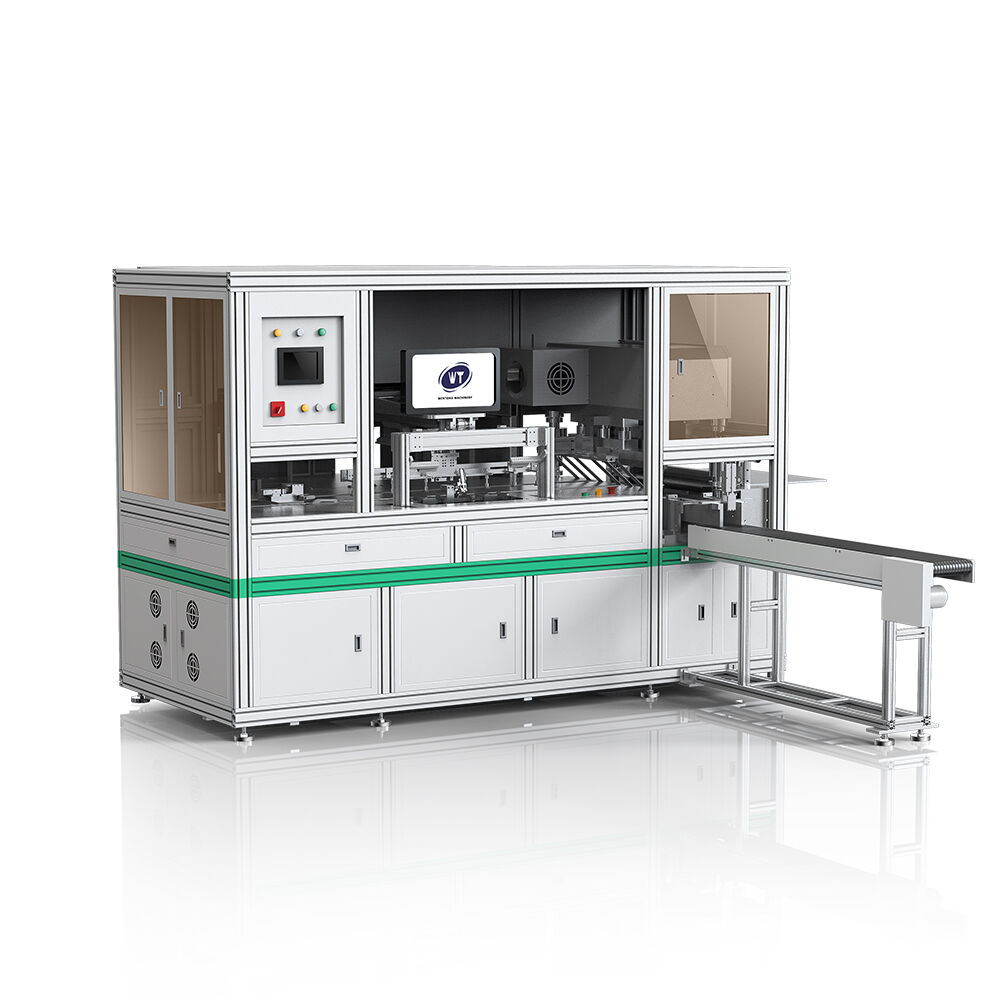

Shenzhen Wentong specializes in manufacturing high-performance bank card punching machines (die-cutting machines) with integrated automatic sorting and hot stamping functions. The equipment is suitable for precision punching of smart cards, game cards, playing cards, etc. The cutting edge is burr-free, and customized collection solutions are provided. It provides mature integrated production solutions for global card making enterprises.

As the demand for smart cards, payment cards, game cards, and other customized cards grows worldwide, card manufacturers need to have efficient, accurate, and stable production equipment to remain competitive. We are a manufacturer based in Shenzhen, China, specializing in precision die-cutting technology. Our main goal is to make high-quality bank card punching machines available to people all over the world. This machine is more than just a punch press; it is an intelligent production system that can automatically sort, hot stamp, and collect items that are unique to each customer. It is built to meet the high standards of the card manufacturing industry for speed, accuracy, and flexibility.

The main idea behind the design of the bank card embosser was to make one machine do many things and work together without any help. It became a card-issuing platform that could be expanded, rather than just a card-issuing machine.

1.Wide range of materials and products: The machine can professionally punch accurate holes in various card base materials such as PVC, ABS, PETG, and paper composite materials. You can use it on most of the popular card products:

There are many kinds of entertainment and cultural cards, such as game cards, collection cards (such as animation cards), playing cards, board game cards, etc.

Special industrial products: such as smart card chip carrier tape, filter paper, insulation gaskets, etc. By changing the mold and settings, the equipment can also quickly punch and form book-style sticky notes and cut out a large number of filter papers of specific sizes. This shows that it has many uses.

2.Integrated hot stamping surface treatment process: the equipment and hot stamping unit are flexibly matched to complete the punching and hot stamping at one time. This not only makes production more convenient and reduces the errors and losses that may occur during the handling of semi-finished products but also ensures the perfect alignment of the hot stamping pattern and the punching contour. This greatly improves the appearance and feel of high-end cards such as VIP cards and commemorative cards.

3.Fully automatic sorting and distribution system: The equipment has advanced built-in functions, which can automatically sort and distribute. You can use visual recognition or programming settings to classify cards on the production line. For example, cards with different patterns, good products, defective products, etc. can be automatically sorted. This feature is needed when you are making personalized cards, mixed edition game cards, or when the quality control requirements for cards are strict. It can also save a lot of time when you need to sort manually.

4.Finished product collection scheme: We have a variety of flexible finished product collection methods to meet the packaging and processing needs of different orders:

5.The equipment has a rigid frame and a precision guiding system to ensure the accuracy of each stamping, and the cut is smooth and burr-free. This directly makes the unique texture and feel of the card better, and there is no need for secondary trimming. This not only makes the product better but also reduces the cost of raw materials.

The bank card punching machine gives a clear answer to the problems encountered by global card makers:

The device works well because it uses tried and tested technology. Here are the most important facts and figures that show its advanced nature and power from a technical point of view:

Standard models can accommodate different sizes, but the most common size is 650 mm x 550 mm. They can also be used with mold layouts that have multiple rows and columns to make the most of the material.

Sorting method: Programmable mechanical arm with suction cup or air blowing device, or high-resolution CCD visual recognition system

Sorting speed: The maximum speed can be the same as the punching speed and the main punching rhythm.

Sorting lanes: Usually there are 2 to 4 sorting lanes, but more can be added if needed.

Hot stamping method: flat press flat or round press flat.

Hot stamping precision: punching precision within ±0.1 mm.

Temperature control range: from room temperature to 300°C, suitable for many different hot stamping foil materials

Intelligent stacking and synchronized conveyor belts make sequential collection possible.

The sorting channel is directly connected to the sorting collection, and it has its own stacker or collection box.

Bank card embossing machines are useful for many customers in other countries because they can be used for many different things.

1.Card manufacturers and printing companies: They make a lot of things, such as bank cards, membership cards, gift cards, etc. Their machines need to be very robust, work well for long periods of time, and have built-in hot stamping capabilities. These machines help them fulfill large orders from banks and big stores.

2.Card and anime derivative manufacturers: These products are often technically very complex, have many different versions, and have very strict regulations on the accuracy of colors and patterns. The automatic sorting function of the equipment can quickly sort the cards and make different images. The quick change feature is ideal for producing extra packs and limited editions.

3.Industrial material processors are companies that do precision punching of gaskets, filter paper, electronic label substrates, etc. They have high requirements for punching accuracy and burr-free, and the rigid structure and precise control of the equipment can meet these requirements.

4.High-end custom card studios: The number of cards produced may not be large, but the requirements for quality, uniqueness, and complexity of the process (such as die-cutting and hot stamping) are very high. This is the case for niche markets, and the same is true for high-end commodity markets. The high precision and flexibility of the equipment, as well as the customized solutions we provide, can meet all their needs.

5.People who are making paper and plastic products full time need to consider making cards and other business, as well as making punched books and filter paper. The equipment is worth the money because it can do many different things at once. This allows you to make the most of your assets and handle many different market orders.

This bank card punching machine from Shenzhen, China, is becoming important production equipment for manufacturers in the global card-making and related industries. With its deeply integrated automation features, precise and stable punching quality, highly flexible process configuration, and cutting-edge design for the global market, it helps them improve the level of automation, ensure product quality, and quickly adapt to market changes. We are committed to helping customers by constantly introducing new technologies and better ways and bringing continuous value growth to global partners.