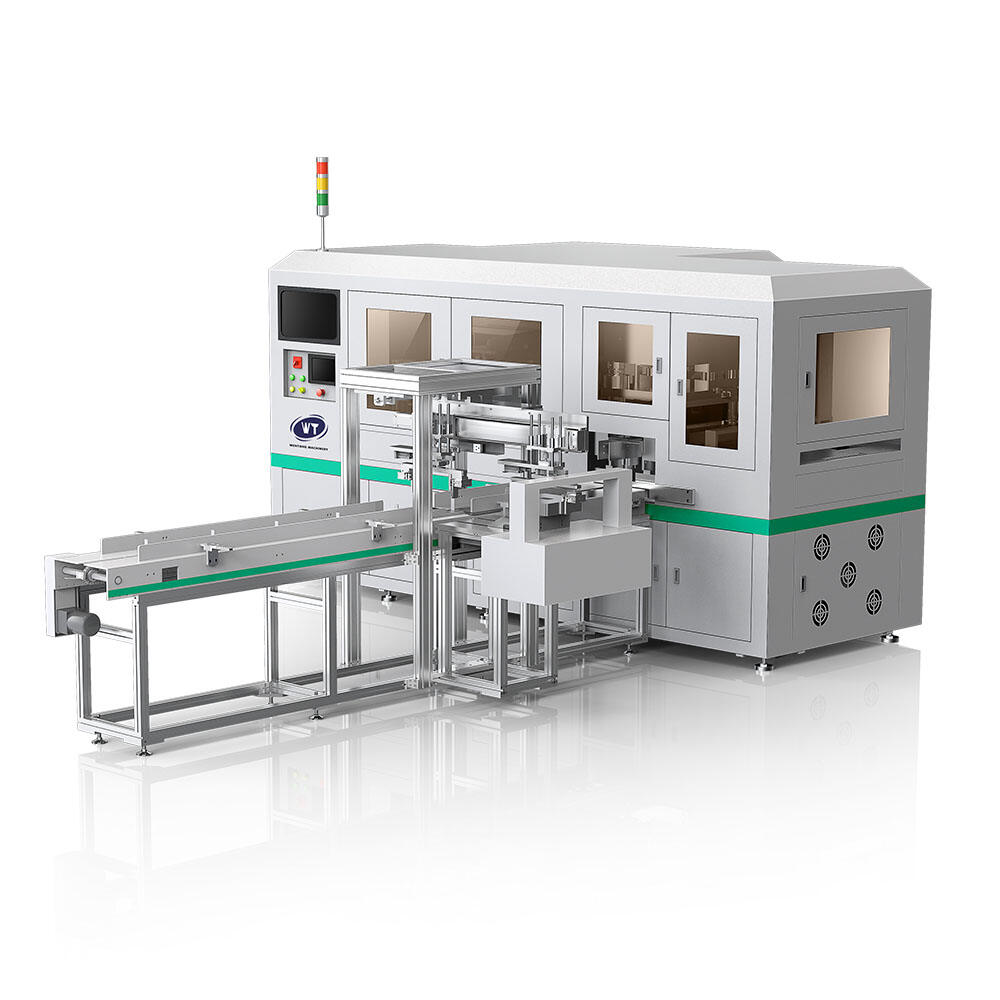

Precision die-cutting is the most important link in the global card-making industry chain, which directly affects the quality, production speed, and cost of the final product. The strict requirements of the market for card varieties, delivery speed, and quality make it difficult for traditional die-cutting machines to meet the requirements in terms of accuracy, maintenance, process flexibility, and production efficiency. For this reason, we rely on the powerful ecology of high-end equipment R&D and manufacturing in Shenzhen, China, to create a new generation of Star Card die-cutting machines. The equipment integrates advanced mechanical engineering, digital servo control, and intelligent automation technology and provides a complete set of full-process customized solutions for global card manufacturers. The following will systematically explain how it changes the efficiency and quality standards of card making from three perspectives: the precise application field of the equipment, the characteristics of the core technology, and the detailed performance parameters.

The design concept of the equipment starts from the needs of terminal products and makes a full analysis. It is widely used in card products with high requirements for dimensional accuracy, edge quality, production efficiency, and process complexity. It can also be easily extended to related precision stamping fields.

1. Payment and Security ID

These products meet the highest standards of reliability and security in the card industry. The main uses of the equipment are

-

Chip card carrier punching: Punching holes in the composite material module (INLAY) inside bank cards, credit cards, and social security cards using a precision punch. The long-term reliability of the card and the protection of the antenna from damage depend on its precise dimensions (±0.05 mm) and burr-free edges.

-

Finished card cutting and pre-personalization: Cut the laminated PVC, PETG, or polycarbonate (PC) card blanks into suitable shapes to provide a perfect base for offset printing, gravure printing, or personalized hot stamping. Can be connected to the personalized production line, automatic sorting, and classification. This allows the items to be collected in order and the coding cards to be retained.

2. Collectibles and Trading Cards

This is the area with the most stringent requirements for the overall performance of the device. It is directly related to the collection value and user experience of the product.

-

High-end collection card production, such as sports star cards, animation and film cards, limited art cards, etc. The equipment must ensure that the cut edges of each card are as smooth as a mirror so that the unique texture of the card material can be seen. The high-rigidity structure and servo control ensure that the pattern registration is 100% accurate. Combined with the hot stamping process, zero-error alignment decoration can be achieved.

-

Making trading cards, such as Magic the Gathering, Yu-Gi-Oh, and Pokemon cards. The equipment's quick mold change capability and parameter memory function have become its most important competitive advantages. This enables it to quickly change products to meet the needs of a fast-reacting market. The automatic sorting system can sort the cards by rarity or series on its own. This makes it much easier to package them later.

3. Mass consumption game entertainment card

These items are made in a way that allows for stable, large-scale production while maintaining extremely low costs.

-

Playing cards and board game cards: machines must be able to produce millions of cards per week, non-stop. Their robust construction and high efficiency ensure that even under heavy loads and long periods of use, the size, feel, and weight of each deck remain the same. This makes the game fair and fun.

-

Promotional cards, membership cards, and phone cards: The device can handle these businesses well because it can do many different things and is fast. One machine can do so many things, which helps printing and packaging companies better manage their production capacity and better utilize their equipment (OEE).

4. Special Materials and More Uses

The equipment has strong punching force and precise control, which makes its application range wider and wider.

-

Special cards: Special cards include thick cardboard cards, metal composite cards, and special-shaped cards.

-

Expanded precision die-cutting: By changing the special die, it can produce the exact shape of high-quality hardcover book covers, the round or special-shaped die-cutting of laboratory-grade precision filter paper, the die-cutting and creasing processing of electronic product lining, and high-end packaging boxes. This flexibility provides users with new ways to develop their business.

2. The main technical features of the Star Card die-cutting machine

All the technical improvements of the equipment are based on the core triangle capability model of "short, flat, and fast." The goal is to find the best balance between speed, quality, and flexibility.

Feature 1: "Short Cycle" Agile Engineering

-

Modular quick die change (QDC) system: The equipment has a standardized interface with hydraulic or mechanical hoop locking and an offline die pre-adjustment table. While the machine is running, the operator can pre-adjust the next set of molds. This allows for a seamless production process, reducing the mold change time from several hours to less than 15 minutes, greatly reducing the standby time of the equipment. This is especially suitable for the production of star cards, game cards, and other products with many varieties and small batches.

-

Full digital intelligent control: It has a large industrial touch screen and a programmable logic controller (PLC) that can store hundreds of product process recipes. When switching products, the correct parameters (pressure, stroke, speed, and positioning point) are called with one click, and the system automatically switches. This saves time and avoids errors caused by manual debugging.

Feature 2: Cornerstone design to ensure stability

-

Extremely rigid frame: The frame is made of high-quality cast iron, optimized by finite element analysis (FEA), and fully vibration-aged to eliminate internal stress and ensure that the deformation is as small as possible under long-term high-speed impact load. This is the key to maintaining long-term accuracy.

-

Servo-driven precision stamping: The main power source is a 7.5 kW high-performance AC servo motor. The motor can respond to precise torque control in milliseconds, which is much faster than traditional mechanical transmission. By optimizing the toggle or crank connecting rod mechanism, the "soft landing" of the stamping process can be realized, the impact on the mold and materials can be reduced, and the operation can be kept smooth and quiet while achieving high-speed stamping of 120 times per minute. This greatly extends the service life of the equipment and molds.

-

Zero-defect edge processing technology: The movement of the upper die is controlled by a precision guiding system (such as a rectangular roller guide rail). The alloy steel die adopts special heat treatment and a mirror polishing process to realize micron-level blade gap control. This not only ensures the repeated positioning accuracy of ±0.05 mm, but also the edge of the cut card is free of burrs, and the perfect texture is immediately presented without additional processing.

Feature 3: "Fast response" is driven by automation and intelligence.

-

Inline integrated process unit: fully automatic flat-bed hot stamping module, available for your choice. The module communicates with the main control system in real time to ensure that hot stamping and die cutting are always synchronized. Decoration and forming are completed in one pass, combining two processes into one. This speeds up the production process and makes it easier to produce high value-added products.

-

Intelligent back-end sorting and collection system: the key to realizing "unmanned" workshop operation. The equipment has an automatic classification and sorting module, which can be used in two ways: visual induction or mechanical triggering. It also has two customizable finished product collection methods:

-

Sequential collection:A high-precision encoder is adopted to ensure that the order of cards made is completely consistent with the order of die cutting. This is very important for lottery tickets, serial number collection cards, and other cards.

-

Collection by category: Cards can be automatically sent to 2-6 independent collection stacks or conveyor belts according to preset standards (such as qualified products/waste products, different color patterns, different product models, etc.). This means that they can be directly used for counting, plastic sealing, or packaging processes, completely replacing manual sorting.

-

Forward-looking customized integration capabilities: We provide complete integration solutions that can be customized according to your needs. Customers can use the equipment as the core module to connect the fully automatic roll material feeder, CCD visual inspection system, high-speed stacker, packaging machine, etc. to form a complete intelligent production line from raw materials to finished product packaging.

Part 3: Key performance parameters of the star card die-cutting machine

The following specific technical parameters are the exact figures for the equipment to run well and reliably. Provide a solid data foundation for customers' investment decisions.

Power supply |

AC 380V/50 HZ |

Sheet format |

Max. (L*W) 1000*700MM

Min. (L*W) 550*450MM

|

Total power |

10KW |

Control |

PLC control + Servo system |

Air source |

6 kg/cm2 |

Operators needed |

1 |

Air consumption |

Approx. 80L/min |

Dimension |

L2800*W1750*H1850MM |

Punching pressure |

2T-6T |

Drive |

Servo system |

Weight |

Approx. 2000KG |

Punched card size |

Max. 140*140MM

Min. 54*54MM

|

Punching accuracy |

±0.05mm |

Productivity |

1200 Sheets/H |

Applicable card materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

It has become the best card-making equipment in the modern world because its high-performance parameters have been thoroughly tested. It goes beyond a single piece of equipment to become a complete solution that can be deeply customized and easily connected. This directly addresses the biggest issues facing the industry in terms of efficiency, quality, and flexibility. Card manufacturers who want to be more competitive in the global market should choose this equipment because it has shorter delivery times, better quality, and more flexibility to market changes. We are eager to take this technology as a carrier to bring the card-making industry to a higher level of automation and intelligence together with global partners.