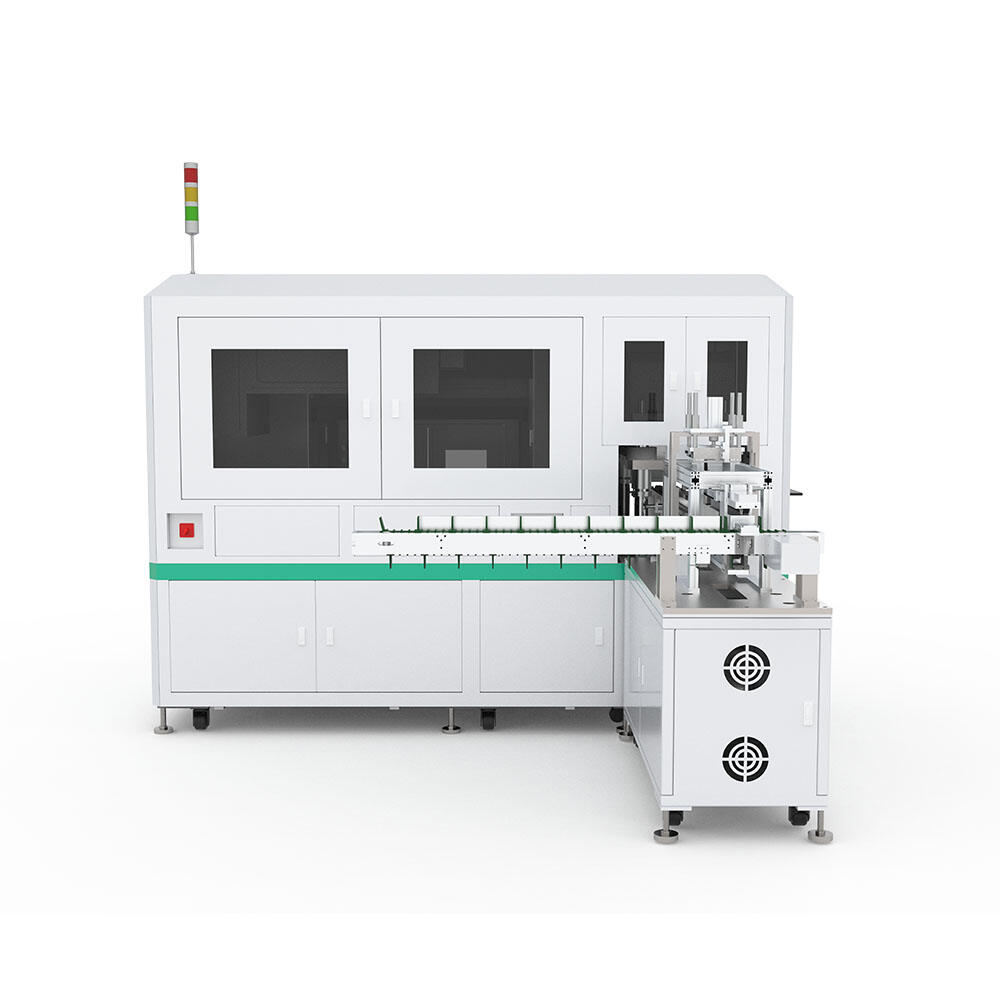

The game card punching machine is widely used in the batch automatic production of animation cards, bank cards, membership cards and other products. The equipment supports rapid mold change and multi-purpose machine. With the automatic classification and sorting system, the efficiency and consistency are improved. View the actual application scenarios and customer cases.

Card products are very popular now. There are game cards, smart cards, bank cards, membership cards, promotional cards, and many collection cards for movies, TV shows, and animations. The quality, speed and consistency of production are directly related to the value and experience of the product. The card-punching process is an important part of card making, which requires high equipment precision, strong stability, and multi-purpose use. The game card punching machine, as a piece of professional die-cutting equipment, meets this high-quality production standard. It's more than just a card-punching machine. It is a complete production solution that includes precision engineering, automated controls, and the ability to change processes based on different needs. This article will introduce the working principle of the equipment, the main problems solved in production, technical details and a variety of application methods in detail. At the same time, it also provides professional technical and knowledge references for card manufacturers around the world.

The production of the game card punching machine is first to make the continuous production more stable and efficient and to ensure the accuracy of the final product. The main functions and features are designed according to the actual problems encountered in the card-making process:

Unique texture and precise punching without burrs: the equipment has a very strong frame and precise guidance system. It also features high-quality alloy steel dies that are heat-treated and ground to ensure clean, crisp punches every time. The cut is flat and smooth, without burrs, rough edges, or delamination. This is very important for game cards, bank cards and other things that want to have a high-end feel. It makes the cards look and feel better, and you don't have to clean them manually later.

Excellent durability and long service life: The main structural parts are made of high-strength cast iron or steel plate welded and then aged. They have a long service life because they are difficult to bend and fatigue. We have selected world-renowned brands for important moving parts such as spindles, bearings, and guide rails. We have also put a lot of effort into the design of the sealing and lubrication oil circuit to ensure that the equipment can still maintain high precision under long-term heavy-duty operation. Effectively improved the maintenance cycle of the mould and the service life of the equipment.

Wide range of applications and multiple use places: Through the rapid replacement of the mould system, the game card punching machine can easily handle the punching needs of cards of various sizes and shapes. This means it can handle a wide variety of card types. It can do far more than cut ordinary cards, because it can apply a lot of pressure and it is very well controlled. It can also die-cut hardback book covers, high-quality filter paper and electronic component washcloths, all of which have high standards for cut edge quality. This means you get the most value for the money you spend on the equipment.

Good coordination with post-press processes such as hot stamping: The equipment is designed with standard process interfaces, and it is easy to add online hot stamping, embossing, coding and other units. The combination of stamping and surface decoration not only greatly speeds up the production process but also solves the problem that the global process cannot be correctly aligned. It ensures the extremely high yield of composite process products (such as flashcards and special effect cards).

Mature and stable core technology and automation: It has a 7.5 kW high-power servo drive system and an intelligent control system based on an industrial PC. It makes the power output stable, strong and accurate. Servo systems are far superior to older mechanical or pneumatic systems in controlling speed, position and response time. It is the basis for fast, precise production and the control of complex movements.

Customised overall solution: It is not selling standard equipment but a complete set of solutions, from selecting the right equipment and designing moulds to automatic connection and taking away finished products. The most suitable production line for customers is the one that matches the layout of the customer's factory, product matrix and production mode.

Intelligent automatic sorting and classification: This is one of the tasks that the equipment can automatically complete. Adding a visual recognition system or sensor to the equipment can realise automatic sorting and classification of cards after punching. For example, when making collectible cards, cards with different patterns and different rarities can be automatically sorted into different collection channels. This reduces a large amount of workload and errors that occur during manual sorting.

The finished product collection method is adaptable and can be changed according to your needs. There are two main ways to collect automatically: 1. Collect in order: Collect strictly in the order in which the cards are punched out. This makes it easy to connect to the previous printing process or the subsequent packaging process. It is also a good choice for card sets that need to be exactly the same. 2. Collect by category: The sorting system connects different categories of cards so that they can be stacked, counted and packaged separately. This is useful for sorting after mixed-version printing.

The above features of the game card punching machine solve many problems that card manufacturers often encounter:

Quality consistency: In mass production, it is difficult for manual or semi-automatic machines to ensure that the edge-cutting quality of each card is the same. The machine is fully servo controlled, and the mechanical structure is very precise, ensuring that millions of punching actions occur in the same position (usually within ±0.05 mm). This means that the quality remains the same.

Bottleneck of production efficiency: Traditional single-punch or low-speed equipment can only produce a small amount of products at a time, resulting in low production efficiency. The machine adopts a high-performance servo drive and an automatic feeding and receiving system, which can run at high speed for a long time. The speed can be adjusted according to the material and thickness of the card, and the highest punching frequency can reach tens of thousands of times per minute. It can run 7 days a week, and the output is much higher.

High labour costs and sorting errors: Manual sorting is costly and prone to errors, especially for game cards and anime cards, which come in a wide variety. The automatic classification and sorting function realises the unmanned operation of the machine. This has reduced labour costs by more than 70%, and the sorting accuracy rate has reached more than 99.9%.

Complex processes are difficult to combine: there are too many equipment and process links, the floor area is large, and the cost is high. The equipment adopts a modular design, integrating the processes of testing, stamping, hot stamping, etc. on one production line. This simplifies the process, reduces material handling, and improves overall yield.

Time-consuming and inflexible mould changing: The equipment has a quick mould changing system, which can complete mould changing and calibration in a few minutes. It meets the production needs of small batches and multiple varieties and can quickly adapt to market changes.

The equipment works very well due to some technical details and parameters:

Power system: The core power adopts a 7.5 kW high-response AC servo motor, which makes the torque output consistent and always adjustable. The high-precision reducer and ball screw/eccentric gear transmission convert the rotary motion into precise vertical stamping pressure.

Control system: An industrial-grade PLC or dedicated motion controller is the brain of the control system. It also has a high-resolution encoder that allows it to fully control the loop. The touchscreen HMI can be set to multiple languages, such as Chinese and English. It is also easy to set and save the production parameters of different products, such as speed, pressure, stroke, count, etc.

Mechanical structure: The mechanical structure adopts an integral gantry or C-type frame structure, and the key components are optimised by finite element analysis (FEA) to ensure the strength. The pre-loaded linear guide rail and maintenance-free bearing are adopted to ensure the smooth and non-jitter movement of the slider.

Precision index: punching and cutting repeat positioning accuracy is usually ≤±0.03 mm, and parallelism error is ≤0.05 mm/m. This means that even moulds with small fonts and difficult-to-cut shapes can be cut perfectly.

Pressure and stroke: The nominal pressure range can be changed as required (usually between 20 tonnes and 80 tonnes), and the stroke can be changed according to the thickness of different materials, from 0.2 mm thick PVC cards to several millimetres thick cardboard.

Automatic connection: standard interface, convenient to connect with automatic paper feeder, visual inspection system, stacker, packaging machine and other machines. Automatic sorting and distribution systems typically use CCD cameras or fibre optic sensors to find preset shapes, colours, or markings. Then, they use robotic arms or pneumatic arms to sort the items.

Safety and environmental protection: It has a two-hand start button, emergency stop device, grating safety protection, etc., to ensure your safety and protect the environment. The equipment runs well, and the noise is not loud. It also meets the environmental standards of the factory.

Many card product manufacturers around the world use the game card punching machine because it is flexible, very precise and can be automated:

Trading card game (TCG) manufacturers, such as Magic: The Gathering, Yu-Gi-Oh! and Pokémon, produce many different cards. This is the most important example of how it's used. The machine can quickly sort through large quantities of cards with different patterns and even sort out rare cards on its own. This is an important tool to ensure that these goods are produced in large quantities and of high quality.

Smart card and security document manufacturers: such as SIM cards, bank cards, credit cards, ID cards, access cards, etc. The requirements for cutting-edge quality and dimensional accuracy are very high. The high precision and stability of the equipment fully meet the standards of security and financial products.

Playing Card and Speciality Card Company: Produces fine playing cards, bridge cards, custom-themed cards, and more. The equipment works best with multi-ply laminated card stock, which has clean edges, so shuffling is very smooth.

Animation and film and television peripheral and promotional products printing enterprises: printing animation and film and television peripheral products, promotional products companies, making a variety of merchants for publicity cards. These are character cards, collection cards, star cards, membership cards, and discount cards. This machine is perfect for small-batch, multi-variety orders because it can change moulds quickly and make many different things.

Packaging and stationery manufacturers: The machine should be used by packaging and stationery companies to cut hardback book covers, gift box paper, high-end notebook covers, industrial filter paper and insulation materials with extremely high precision. This will demonstrate the practicality of "one machine for multiple uses".

Located in Shenzhen, China, Wintone has rich experience in mechatronics technology. It is also close to the world's electronics and manufacturing supply chain. The company's game card punching machine is globally competitive in terms of performance, reliability, and cost performance. It has been successfully sold to major markets around the world, such as Europe, North America, Southeast Asia, Japan, and South Korea. Today, many of the world's leading card brands trust it and use it as their equipment supplier. When you buy one of these machines, you are not just buying a machine; you are buying a modern production system that can make products better, cheaper, and faster to market.