The invention of punching machines has transformed the manufacturing industry, offering unparalleled efficiency and accuracy ior value add metalworking operations. It is one of the most useful tools for achieving intricate shapes on various materials as it ensures every design made is punched out precisely. With technology, advancements, today’s punching machines have additional features that improve their output making these machines essential for all businesses out there hoping to optimize their productivity and minimize on wastage and defects.

Among the different sectors in industrial manufacturing, the need for reliable and accurate punching machines has intensified. Businesses are now purchasing new commanding technologies due to the increase in demand coming from customers. The capacity to create challenging forms while using minimal resources is one major advantage that these punching machines bring to the table. Ultimately, these benefits not only create profits for the company, but also promote sustainable practices that help protect the environment.

Like many modern machines, today's punching machines have added features that improve their overall efficiency. For example, CNC (Computer Numerical Control) features fully automated processes, which considerably improves both speed and accuracy of production. Programmable CNC punching machines allow operators to set a number of operations, thus reducing the chances of human blunders, achieving uniformity in quality for each punch done. Also, the new “smart” technology integration allows for real-time monitoring and computerized inspections, diagnostics, maintenance scheduling systems, and so forth, which help in minimizing downtimes and machine idle time.

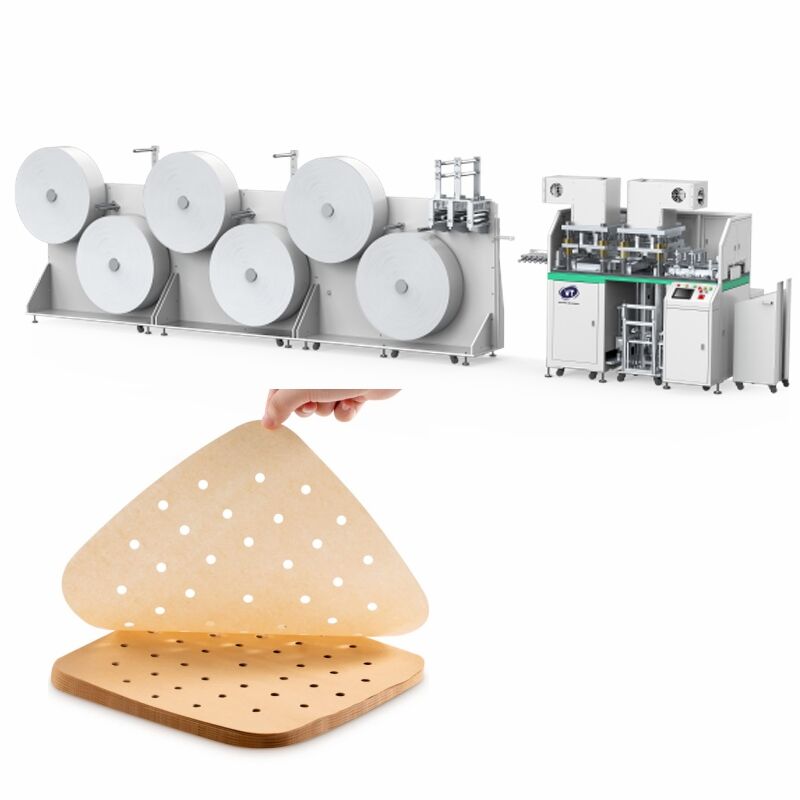

On the other hand, punching machines are versatile as it relates to the types of materials that one can be worked on which may include metals, plastics and even some composites. Applications vast across many industries such as automotive as well as electronics. The standards offered by punching machines allows manufacturers to satisfy the ever-increasing quality expectations of their customers.

With industries evolving with time, the capabilities of punching machines has also improved. The move to automation and smart manufacturing have been the most essential factors in the development of advanced punching technologies. Machines have always been designed to achieve a certain level of accuracy; however, these days, there is still a need for compatibility with automated systems in the production line. The direction that manufacturing processes are heading towards is what will influence the development of punching technology, thus opening up more possibilities for innovation as well as efficiency.

To sum up, punching machines are essential for precision accuracy in production processes. As punching technology improves, it will continue to become even more important in fulfilling the requirements of contemporary production. Businesses that invest in quality punching machines will experience enhanced effectiveness, less product waste, and the ability to provide high-quality products to their clients. Innovations in punching technology continue to emerge, ensuring that the sustainability of advancements in performance and capability will endure.