In industries such as playing cards, membership services, smart cards, and filter paper, the requirements for product accuracy and production efficiency are getting higher and higher.

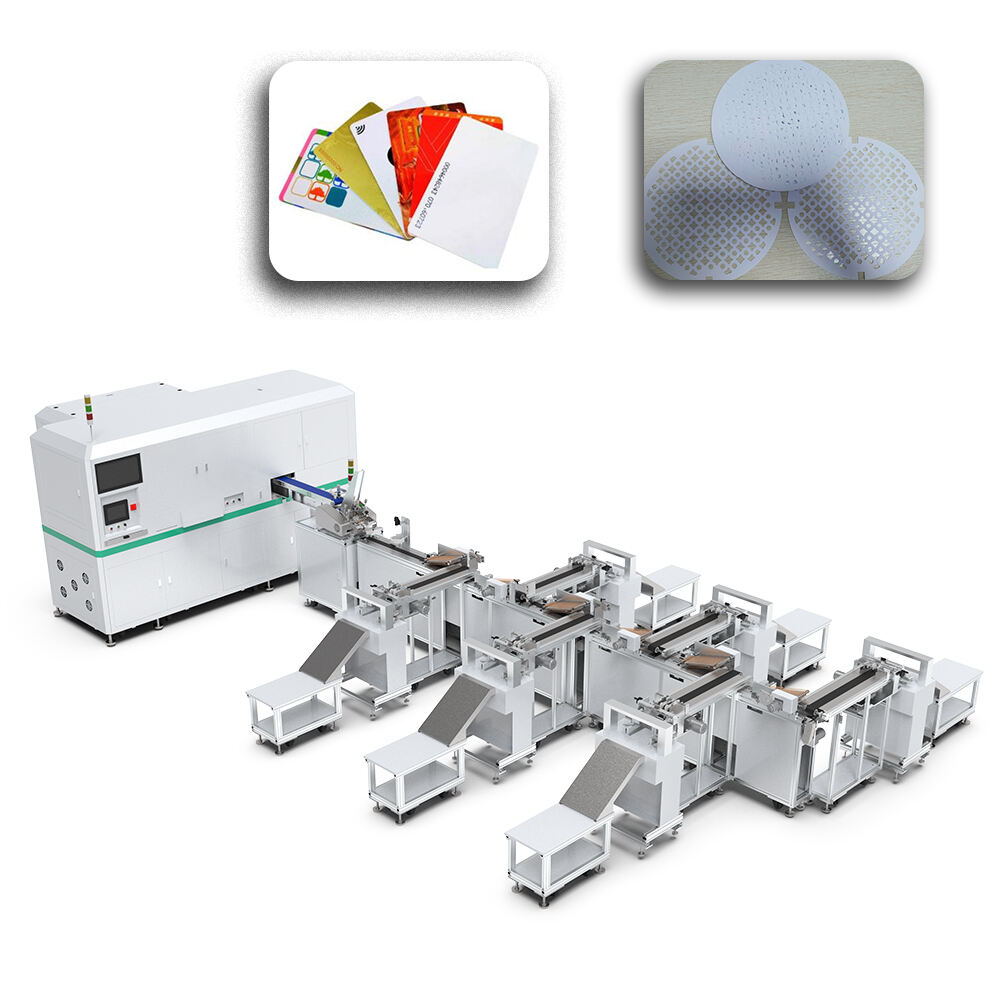

In industries such as playing cards, membership services, smart cards, and filter paper, the requirements for product accuracy and production efficiency are getting higher and higher. To meet this demand, Shenzhen's leading industrial equipment manufacturing hardware company has designed a card punching machine that integrates sorting and hot stamping and has launched it on the international market. Using advanced technology and fully automatic systems, we provide card developers, filter paper manufacturers, printers, etc. with excellent cost performance and one-stop streamlined solutions.

The punching machine can efficiently punch various materials such as paper, fiber, wood, and plastic:

game cards, membership cards, smart cards, postcards, greeting cards, etc.

oil filter paper, steamer paper, coated paper, filter paper, etc.

calendars, books, brochures, document bags, envelopes, etc.

It has a unique automatic sorting and distribution system, which can collect and store finished products in a specific order or collect finished products by category according to user requirements. This feature greatly improves the production efficiency of the assembly line.

1. Unique texture presentation

Thanks to the precision mold and pressure control, the edge of the card after stamping is smooth and burr-free, perfectly showing the fine texture and surface flatness of the high-quality card.

2. Excellent durability

The card cutting machine adopts high-strength steel, which is wear-resistant and durable, and can run under heavy load for a long time. Its service life exceeds the industry's expectations and reduces maintenance costs.

3. One machine for multiple uses, covering the needs of multiple industries

The same machine can flexibly realize the two functions of game cards and filter paper by changing the mold. It improves the utilization rate of production capacity and reduces equipment investment.

4. Optional hot stamping process

With hot stamping technology, the surface hot stamping is completed at the same time as punching and cutting, which meets the higher requirements of cultural and creative products, decorative membership cards, and so on for esthetics.

5. Mature technology and strong stability

From years of R&D experience, the card punching machine runs stably with an extremely low failure rate and is very suitable for large-scale continuous production.

6. Customized overall solutions

We provide full customization services and tailor mold design, production technology, and finished product collection methods according to the different raw materials and output requirements of customers.

7. Automatic sorting and distribution system

Programmable in the finished product:

① Sequential collection: Keep a set of cards and a series of products intact;

② Classification and collection: Products of different specifications are automatically classified and distinguished, which is convenient for packaging and delivery.

8. High-efficiency power system

Equipped with a 7.5 kW servo motor, the punching speed and precision are improved synchronously, with fast response and low energy consumption.

9. Flexible finished product collection scheme

Users can choose to stack in order to avoid mixing materials and simplify subsequent processing according to the characteristics of the product or choose to pack them in boxes.

10. Accurate punching, no burrs, and no tearing

The intelligent control of the high-rigidity guide rail and positioning system ensures the dimensional accuracy of each piece of cardboard and filter paper, with an error of -0.1 mm to +0.1 mm; the edges are smooth, and no secondary processing is required.

The time clock is optimized for the following types of businesses:

provide efficient production and quality requirements for a large number of game cards;

combine customized hot stamping designs with rapid mass production;

It can produce small batches of multiple categories;

expand business scope to card and filter paper processing and production;

Precision punching of various industrial and food-grade filter papers.

Based in Shenzhen, relying on the Chinese manufacturing supply chain and international technical team, we focus on providing global customers with:

High cost-performance ratio equipment: more competitive price under the same function;

Full-cycle technical support: full response from installation training to after-sales maintenance;

Fast delivery capability: The combination of standardized modules and flexible production shortens the delivery cycle.

Conclusion Beyond being a piece of equipment, the card punch is used to increase production capacity, ensure consistency, and support business growth. Whether in card production, filter paper processing, or diversified printing business, the equipment can become an important core tool on the production line with its performance and flexible adaptability.