The card-making industry today regards the membership card die-cutting machine as the key production equipment for accurately and efficiently cutting and making various cards. Membership cards, smart cards, business cards, paper cards, and even wood cards all need to use die-cutting machines. As the demand for global card production automation, personalization, automated production, and card sorting increases, die-cutting equipment is becoming more automated, high-precision, and industry-standard. This article attempts to analyze the technical characteristics, application scenarios, and competitive advantages of membership card die-cutting machines in the global market. Provide professional guidance for overseas customers.

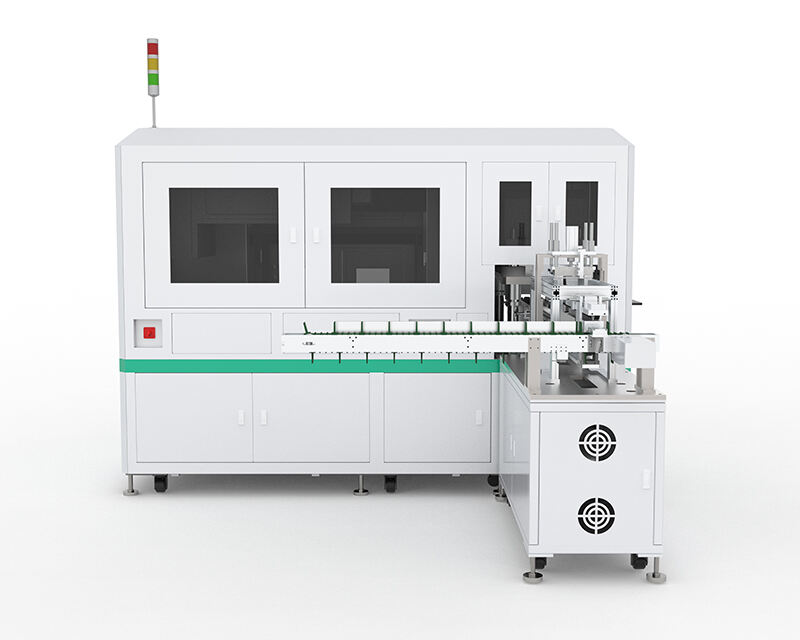

The membership card die-cutting machine is developed for precise die-cutting and card forming. The key modules of the machine include high-precision multi-axis positioning separation, multi-functional mold accessories, and hierarchical automatic sorting and classification. The machine is equipped with an advanced servo control system to ensure that the card edge is cut without taper and smooth. The machine also supports various other material handling, such as ABS, wood composite, and PVC. The sorting function uses a visual positioning chute to achieve rapid sorting and stacking of cards of different sizes and shapes. Practice has proved that this function greatly improves production efficiency.

The die cutter can accurately cut membership and smart cards into ISO standard sizes and shapes, as well as untouched chip embedding areas and strict standards set for financial, transportation, and access control cards.

It can quickly and at high speed die-cut paper materials of various thicknesses and is an ideal choice for mass production of business cards, promotional cards, and gift cards.

Using customized molds, the machine can work with wood and metal composites and other green materials to reach the high-end customized market.

suitable for multi-variety mixed batch and small batch production scenarios. Achieve complete separation and classification packaging, reducing labor.

The automatic sorting function of the membership card die-cutting machine is realized through the following technologies:

The sorter's chutes are controlled by high-resolution cameras that track cards by color, pattern or code.

The chute and conveyor belt are seamlessly synchronized to grab and stack the cards, and more than 1,000 cards can be completed in one hour.

Users can set sorting rules through the touch screen, flexibly adapt to multi-language interfaces, and meet the needs of global customers.

Our company is located in Shenzhen, China, and is a major manufacturer of membership card die-cutting machines, with products sold to Europe, the Americas, and the Middle East. The machine adopts reliable components such as a Siemens motor and Omron sensor, meets CE and UL certification, and provides reliable global service. Ensure continuous global operation and perfect after-sales service. Customized forms, sorting, and speed solutions to reduce overseas operating costs and enhance global competitiveness.

The card die-cutting machine is the key to the enterprise's automation upgrade. It has the characteristics of precision cutting, multi-material compatibility, and intelligent sorting. At the same time, it provides production solutions for global customers. International buyers also understand that the equipment is a product with superior cost performance and obtain continuous optimization of product technical support. Buying products from a mature brand in Shenzhen, China, can get you perfect technical support.