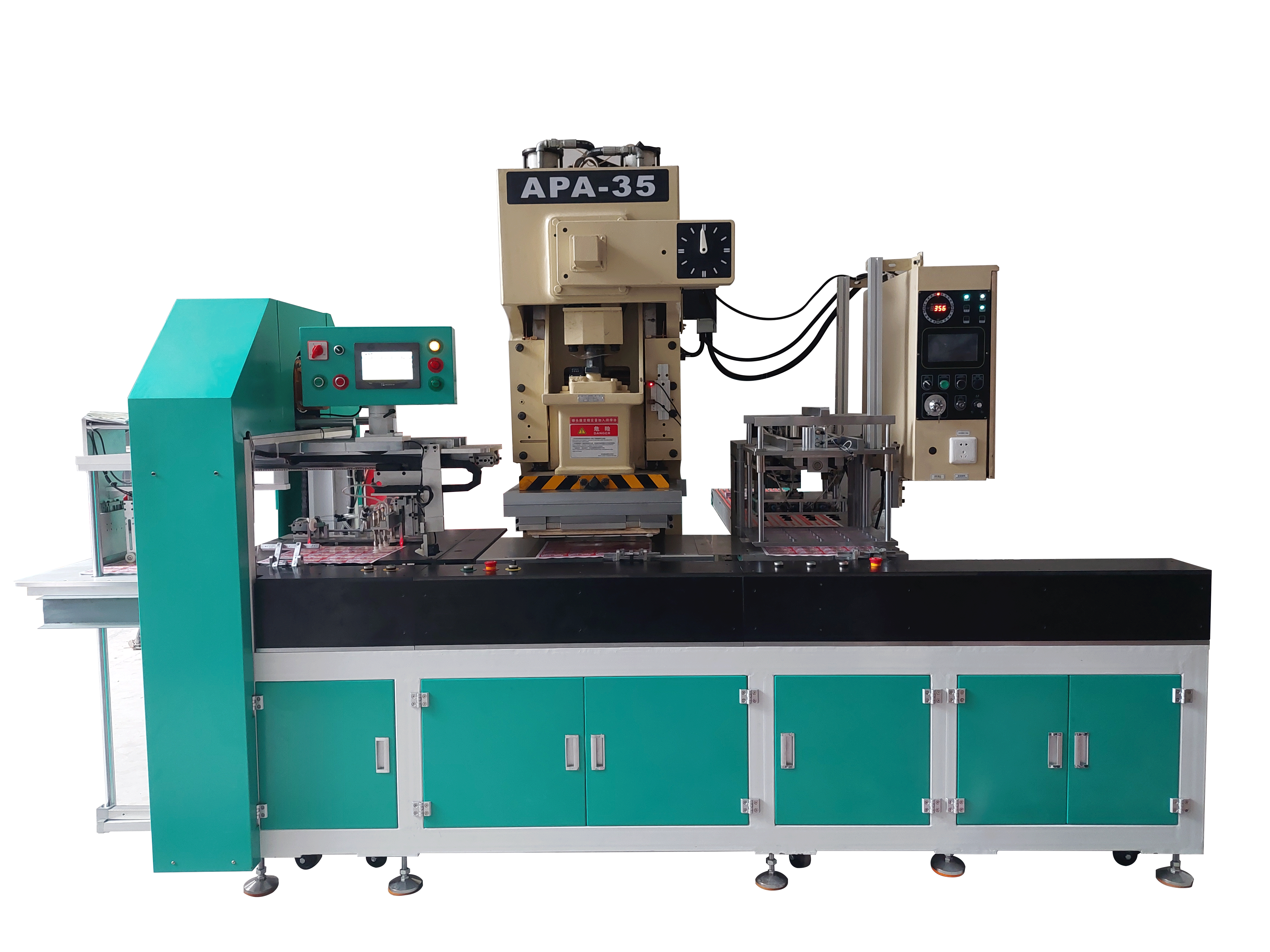

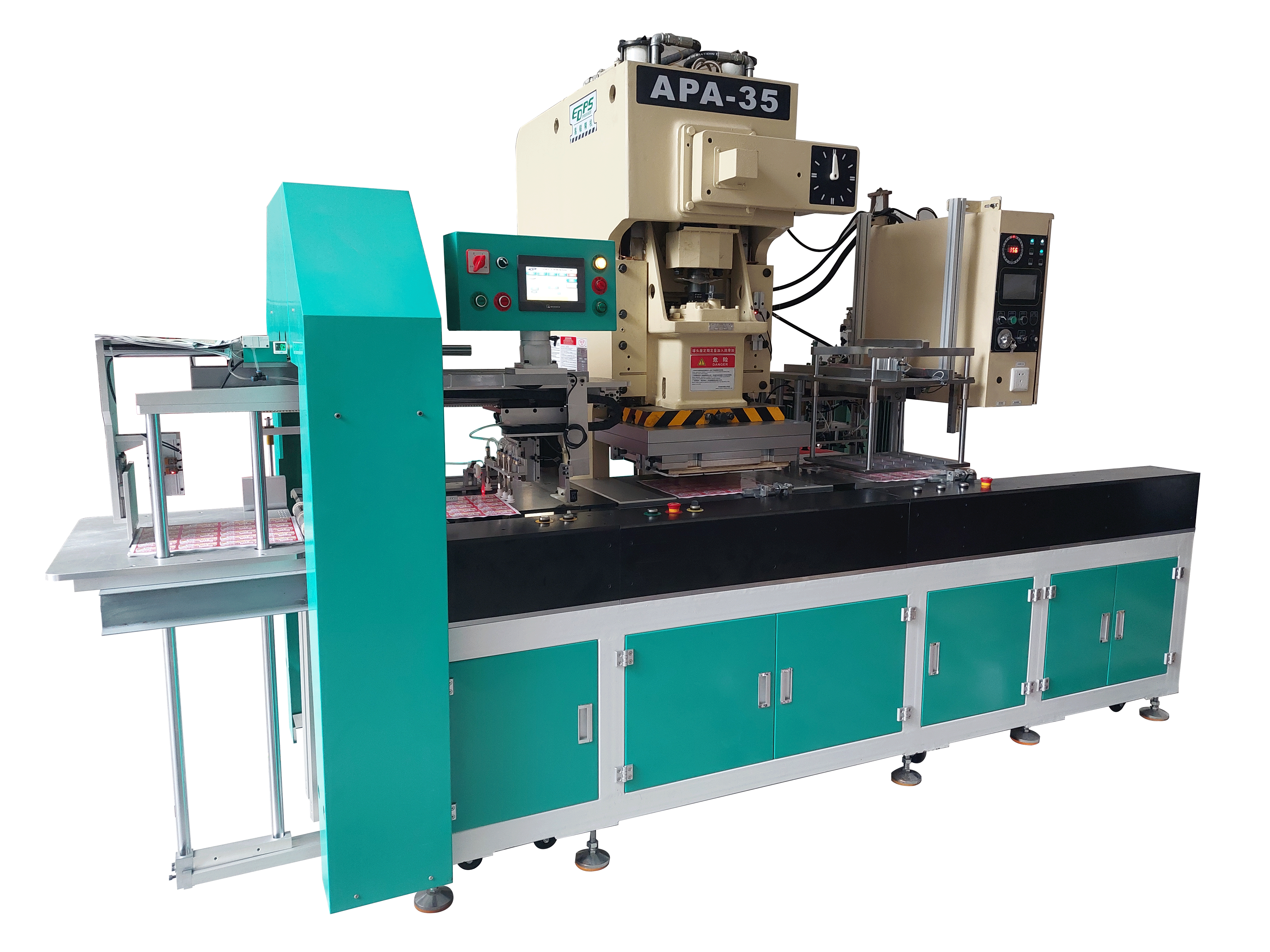

The fully automatic magnetic card punching and cutting machine is an industrial-grade piece of equipment specially designed for high-precision punching, cutting, and sorting of soft magnetic, paper composite materials, PVC, and other special materials.

The fully automatic magnetic card punching and cutting machine is an industrial-grade piece of equipment specially designed for high-precision punching, cutting, and sorting of soft magnetic, paper composite materials, PVC, and other special materials. It integrates high-precision punching, hot stamping, automatic sorting, and customized material collection and aims to provide efficient, stable, and flexible one-stop production solutions for manufacturers of refrigerator magnets, magnetic cards, filter paper, and other products. As the core unit on the production line, it can significantly improve product quality, optimize the production process, and reduce the overall cost.

The fully automatic magnetic card punching machine adopts the modular design concept and integrates modules such as feeding, punching, hot stamping (optional), visual recognition (optional), sorting, and receiving on the basis of the high-rigidity machine base. The core working principle is as follows:

The entire system is automated, and the single-piece punching and sorting do not require manual intervention, ensuring the speed and consistency of the entire operation process.

| Project | Specifications and configuration instructions |

| Core power | The 7.5KW high-performance servo motor system provides stable, accurate and energy-saving power output. |

| Blanking accuracy | ±0.05mm, ensuring that the outline of the punched product is clear and the edge is free of burrs. |

| Applicable materials | Soft magnets, magnetic stickers, PVC, paper materials (such as filter paper), self-adhesive paper, etc. |

| Standard production rate | 900-1200 times/hour (depending on the mold and the complexity of the product). |

| Automation | The standard automatic classification and sorting system supports classification according to patterns, shapes and other conditions. |

| Finished product collection method | Customized finished product collection method: supports two modes, collection in order and collection by category. |

| Process integration | Optional online hot stamping module can be equipped to realize the integrated operation of die cutting and hot stamping. |

| Control system | Industrial-grade PLC + color touch screen, easy parameter setting, real-time monitoring of running status. |

| Mechanical structure | The high-strength steel plate is welded as a whole and treated with stress relief to ensure the durability and long-term stability of the equipment. |

| Power requirements | 380V / 50Hz / 60Hz (can be customized according to the customer's regional standards). |

The fully automatic magnet card punching machine adopts a four-column guide structure or a gantry guide structure, and the punching die adopts special alloy steel to ensure the verticality and parallelism of the punching die. This improvement in stability, especially in soft magnets, has solved the problems of wire drawing and burrs that are common in the industry and has given refrigerator magnets and other products a soft feel and a texture that is of great market value.

The fully automatic magnetic card punching machine integrates a unique automatic sorting system. The system greatly improves the sorting efficiency of mixed production of multiple products or batch orders before shipment. This "unmanned" production system has a unique embedded system.

The fully automatic magnetic card punching machine is essentially a platform for customized solutions. In addition to standard punching and waste removal, we can also match hot stamping, detection systems, two-dimensional code marking, and other functions according to your production needs. This stackable design is flexible, allowing one machine to be used for multiple production purposes, thereby significantly improving the user's return on investment.

Compared with the traditional clutch motor, the 7.5 kW servo motor has the advantages of high efficiency, precise control, small maintenance, low noise, and low energy waste. This is the main basis for the durability, precision mechanical control of the stamping speed, position, pressure, etc., and also the embodiment of the technical content of the equipment.

Customized production needs require both hardware and software considerations. Therefore, we offer flexible software programming to customize the way finished products are collected, and we offer customized hardware for collection box layout and downstream packaging equipment integration to ensure that the equipment is seamlessly integrated into your smart factory.

Scene 1: Production of cultural and creative refrigerator magnets

Process: soft magnetic coil material → automatic feeding → high-precision special-shaped stamping → automatic classification (according to pattern/color) → collection by classification.

Value: The finished product can be produced at one time and can be directly packaged, with an efficiency increase of more than 200%.

Scene 2: Magnetic card and filter paper punching

Process: composite material → automatic feeding → precision stamping (no burrs) → automatic sorting (qualified/unqualified products) → orderly collection (convenient for packaging).

Value: To ensure the card edge is smooth and feels good, the filter paper is punched and cut to the accurate size without burrs.

This fully automatic servo magnet punching machine is not only a machine but also a strategic asset for you to improve the level of production technology and cope with the challenges of the future market. We are committed to combining reliable equipment with mature technology and forward-looking automation concepts to create real value for global manufacturing companies.

Feel free to contact our international business staff for customized solutions, detailed technical documentation, or to set up an online test run. Based in Shenzhen, China, we have successfully served customers in more than 50 countries and regions around the world.