With the increasing popularity of the Internet of Things and the rapid development of intelligent technology, RFID technology has been more and more widely used around the world. RFID cards are widely used in payment cards, access control systems, identity recognition, and other fields and have become an indispensable part of people's daily life and business activities. RFID card die-cutting machines have become an indispensable part of RFID card production with their unparalleled precision and efficiency. This article will delve into the technology, possible use cases, and global market value of RFID card die-cutting machines, as well as the services they provide to industry customers.

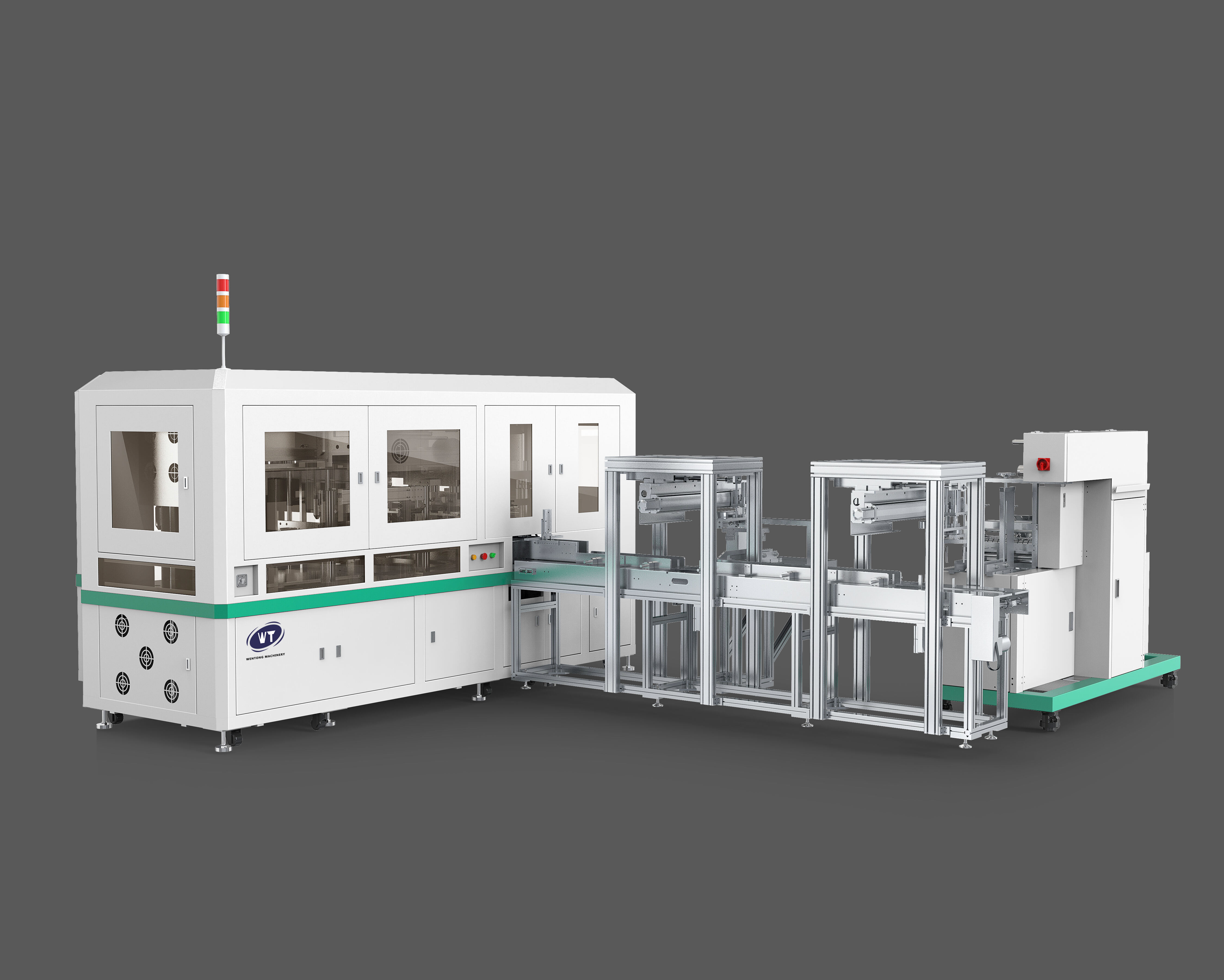

The RFID card die cutting machine is designed for the forming and cutting of various cards to achieve precision. This model can be used for die cutting of RFID cards, smart cards, paper, and even wooden cards. And it adopts a mold and automatic control system to realize high speed and fast cutting. Finally, it has an automatic sorting system, which simplifies the operation and improves the quality and efficiency.

The die-cutting machine uses a servo drive system and high-precision die-cutting to ensure that the cutting error is less than 0.1 mm. This is critical for smart card and RFID card cutting, as cutting too high can damage the internal components.

PVC, PET, paper composite materials, wood veneer, and other substrates are all within the processing capacity of the equipment. As long as the appropriate mold is replaced and the parameters are fine-tuned, the production needs of various thickness substrates can be met. This versatility is unmatched.

Advanced RFID card die-cutting machines use vision system integration and robotics to automatically sort, count, and package complete cards. This capability not only minimizes the number of workers required but also greatly reduces the level of errors made during the production process.

Operators can observe the real-time production status, continuously modify parameters, and store and retrieve production data through the PLC or industrial computer control system. Some mid-to-high-end echelon systems also provide indirect access to "things" for remote operation and maintenance fault diagnosis.

large-scale production of bank credit cards, transportation cards, membership cards, etc.

RFID tags and cards for logistics, retail, asset management, and other fields.

such as wooden gift cards, paper coupons, and personalized custom cards.

It can be linked with the front-end printer and the back-end coding equipment to form a fully automated production line.

As for the rest of the world, the smart card market is still growing and is expected to exceed $30 billion by 2028. Therefore, card die-cutting machines used to manufacture RFID cards are considered to be important assets in the card manufacturing industry. The continued growth of the smart card market in these regions indicates that production automation and the quality of the customer's final-grade products will grow rapidly.

Shenzhen, China, is not only an important production base for electronic manufacturing equipment in the world but also a major town for the R&D and production of RFID card die-cutting machines. Local enterprises, relying on technological innovation and the rapid development of the industrial chain, provide the market with high-performance equipment that meets international standards.

Our equipment is based on years of technical accumulation and customer feedback to continuously optimize, with the following core advantages:

Over the years, automation has developed rapidly, and so has the international RFID card die-cutting machine. This technological advancement helps companies increase productivity, reduce costs, and stay ahead of the curve in the manufacture and development of smart cards and other types of cards. If you need a supplier, please feel free to contact us. However, there is still a gap in the market for automated solutions that can help smart card manufacturers improve productivity. This is a gap we can help fill.

The productivity gap in the market is a problem, and we have the solution. This means you need to have automation equipment available. Currently, our systems are supplied to over 50 countries worldwide, and our equipment is efficient, durable, and long-lasting, eliminating the problems of low productivity and unstable infrastructure.