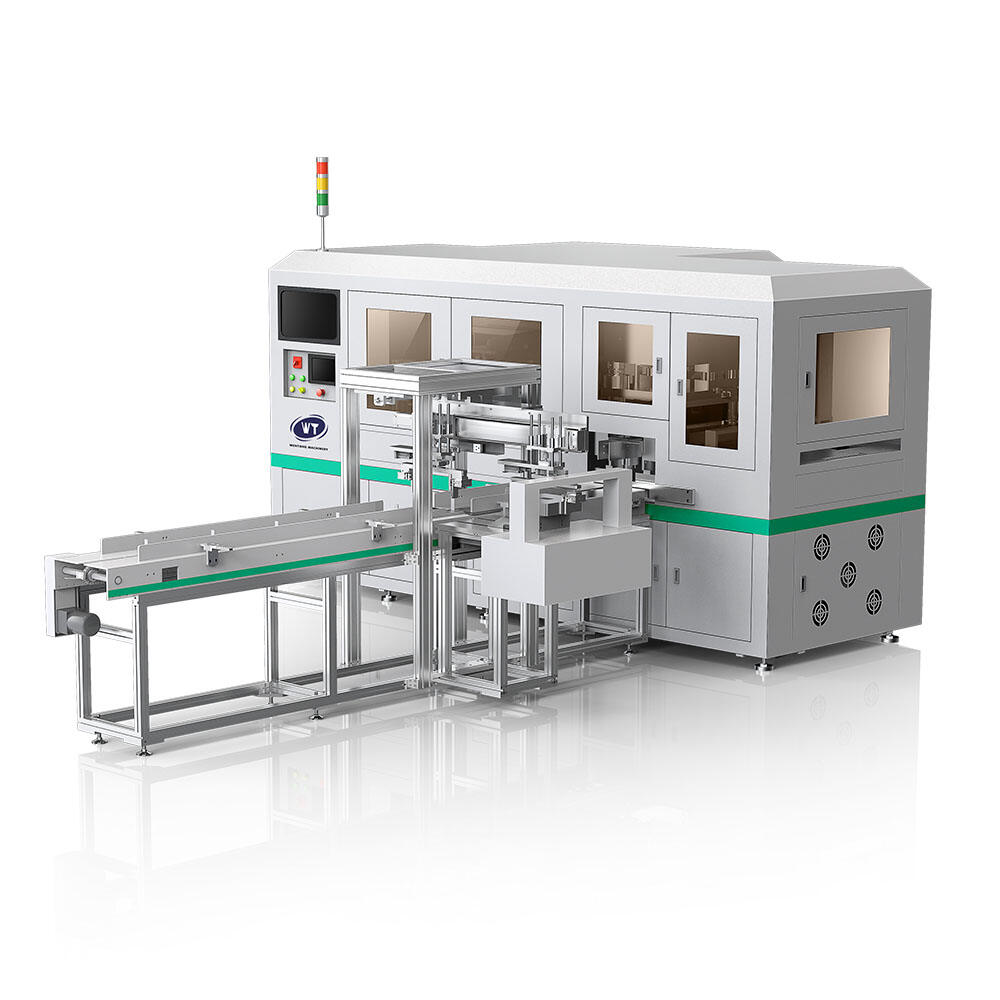

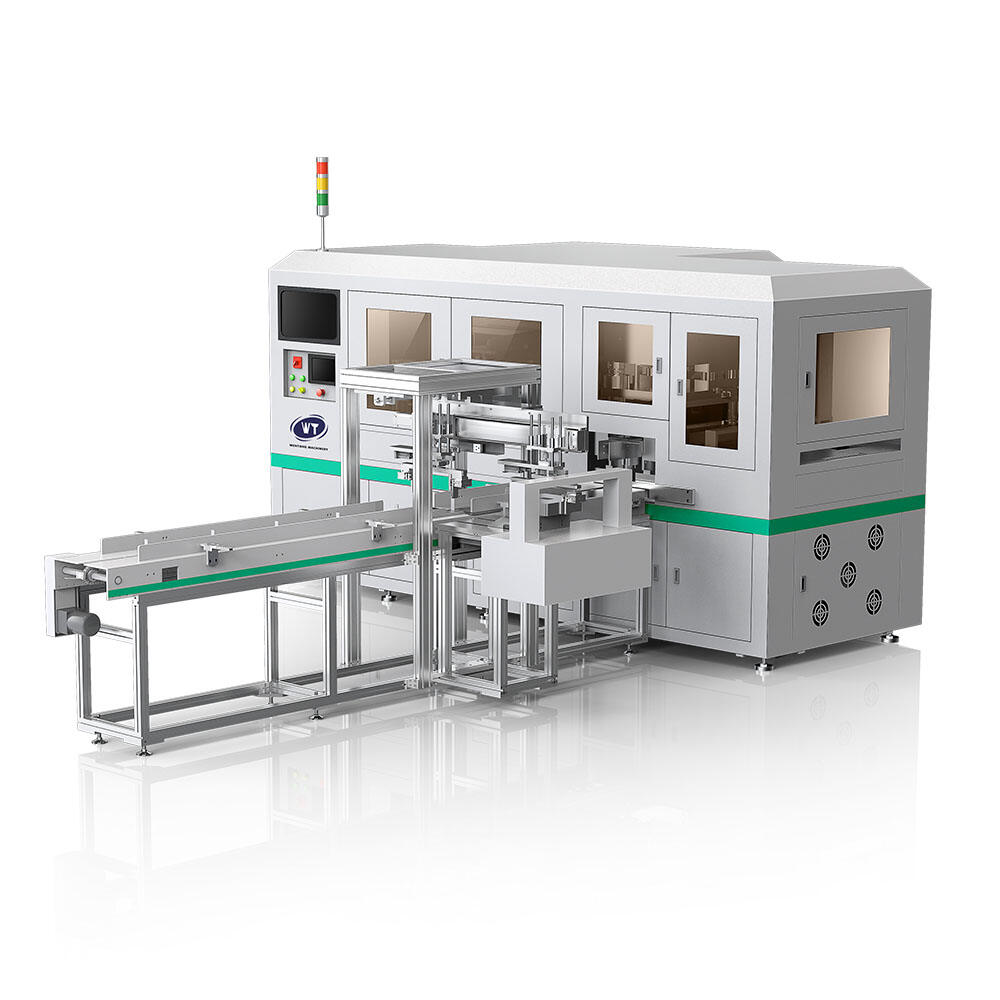

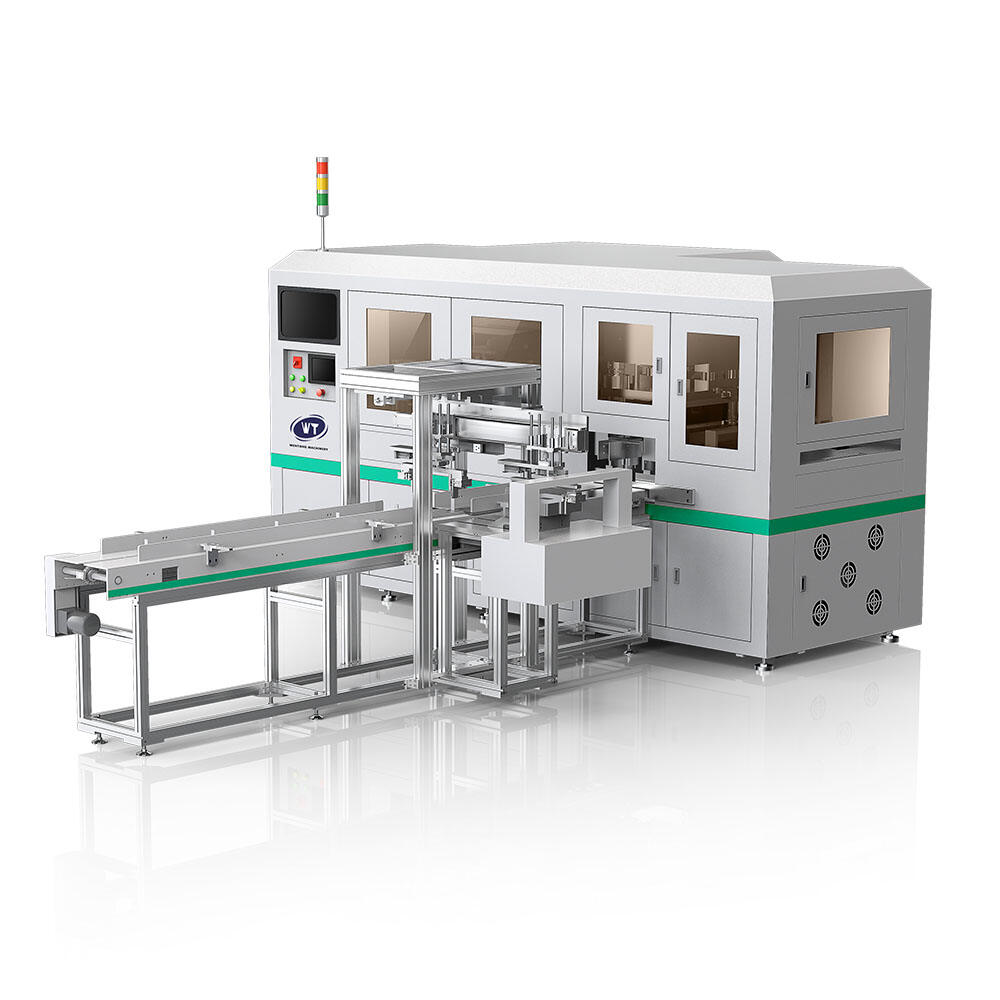

Transparent cards have become an important way to showcase a brand's premium quality and make it stand out in the high-end card manufacturing industry. This is because they have a unique look and feel. The market for transparent cards has been growing, and they are being used in an increasingly wide range of ways. They can be used for luxury membership cards, high-end hotel access cards, collectable game cards, and smart ID cards. However, the production process, especially the die-cutting process that determines the quality of the final product, has many problems that ordinary die-cutting machines cannot solve. When traditional die-cutting machines are used to die-cut transparent materials, problems such as white edges, cracks, obvious stress lines, difficult-to-control cleanliness, and difficult-to-control positioning registration often occur. These problems lead to low production yield, low efficiency and poor quality. To achieve this goal, the professional-grade transparent card die-cutting machine we launched for the global market is not a simple modification of standard equipment. From design to functional configuration, it is a complete production system designed from scratch to meet the physical and quality requirements of transparent and special card materials. The equipment is committed to providing stable, efficient and high-quality transparent card die-cutting solutions for card merchants around the world. It also completely solved the last step of the transparent card production.

1. Fully understand the main problems and process requirements of transparent card die cutting.

Cutting transparent cards with a die is a complex process that combines materials science, precision mechanics and process control. The main problem lies in the characteristics of the transparent material itself:

-

Optical grade edge quality requirements: The best thing about transparent cards is that they are completely transparent. Under the light, any white spots, cracks, atomisation, and burrs on the cutting edge will be magnified to form glaring defects. A perfect cut should maintain the same smoothness and transparency as the card surface and achieve seamlessness.

-

The processing difficulty brought by the mechanical properties of materials: transparent substrates, such as PETG (polythene terephthalate-1,4-cyclohexanedimethanol ester), PVC (polyvinyl chloride), PC (polycarbonate), acrylic (PMMA) and other transparent card substrates, have different hardness, brittleness, thermoplasticity, etc. During stamping, if the pressure curve, mould angle and speed control are improper, the material is prone to brittle fracture or plastic deformation, resulting in micro-cracks or stress concentration areas. This will reduce the strength of the card and make the aesthetics worse.

-

The dilemma of high-precision registration and positioning: The problem with high-precision alignment and positioning is that the material is transparent, so the visual positioning marks that are usually based on optical contrast may not be easy to see, especially in multi-layer composite or all-transparent designs. To achieve this, the equipment needs a high-definition visual system at the sub-pixel level or very precise mechanical positioning.

-

Cleanliness control during production: During punching, static electricity easily causes fine plastic chips and dust to be adsorbed on the surface of the transparent card. Re-cleaning is not only costly but may also scratch the surface. Therefore, a "dust-free" or "dust-on-demand" production environment is a must.

-

Thermal management requirements: High-speed continuous stamping will generate frictional heat, which will increase the temperature of specific areas of the material, change its mechanical properties, cause slight dimensional deformation or adhesion, and affect the consistency of mass production.

Each functional module of this transparent card die-cutting machine is designed to systematically solve the above problems and ensure that the entire process from roll or sheet input to finished product sorting meets the high standards of the best transparent card manufacturers.

Precision cutting function system of transparent card die cutting machine

This is the most important value of the equipment, and it is also a project that requires the coordinated work and precise cooperation of multiple subsystems.

-

Ultra-rigid gantry frame and precision guiding mechanism: The equipment base adopts a high-quality cast iron frame designed by finite element analysis. This makes it more rigid and more resistant to vibration than other models. Ultra-precision linear guide rails and heavy-duty bearings with adjustable pre-tightening force ensure the straightness and verticality of the punch movement trajectory and do not shake even under the impact of hundreds of tonnes. This is the physical basis for obtaining stable and uniform slit quality and avoids uneven or inclined slits that may be caused by frame bending or too small guiding clearance.

-

Servo punching system, best for transparent materials: The drive system uses a high-performance AC servo motor and precision reduction mechanism, and the pressure output is accurate and easy to control. The programmable pressure-displacement curve is the most important part. The best stamping speed, pressure holding time and return speed can be set for different transparent materials, such as PETG with good toughness and PC with good brittleness. For example, the "fast-through-slow-off" curve for PC materials can help get rid of stress lines. PETG, on the other hand, requires higher sustained pressure to ensure a smooth cut. This adaptive pressure control is the most important thing to prevent material breakage.

Special blade mould technology and temperature control system:

-

Mould: Multi-level mirror-polished special alloy steel knife mould. The blade is treated with special micro-geometric angles and coatings (such as DLC diamond-like coatings) to make it high in hardness and wear-resistant. At the same time, it also makes cutting easier and reduces friction. This design makes the cutting process more like a "precise tear" than a "forced cut", which helps to obtain a nearly perfect clear cut.

-

Temperature control: A mould temperature control system can be optionally added to keep the cutting mould at a suitable temperature for cutting different materials. This prevents the material from suddenly cooling or heating up in certain areas due to the temperature difference between the mould and the environment. This also helps maintain consistency of the cutting edge, especially in shops where temperature and humidity vary widely.

2. Ensure that the high-yield clean production and dust removal system is always in operation.

-

Integrated dust removal and fully enclosed stamping unit: The main stamping area is enclosed, and a multi-stage dust removal device is built in. To eliminate static electricity and prevent dust from adhering to the material, an ion wind bar is set at the material inlet. Secondly, there is a high-pressure airflow air knife next to the mould, which blows the debris generated after cutting away from the cutting area as soon as possible. Finally, the negative pressure dust extraction pipe collects all the debris and sends it to the external filter cartridge. This system ensures that the punching process takes place in a dust-free area and produces clean cards immediately.

-

Long-term accuracy maintenance and intelligent monitoring: The key motion pairs adopt an automatic central lubrication system, and special grease is injected regularly to ensure long-term accurate operation. The equipment has a built-in sensor network to monitor important factors such as pressure, displacement, and temperature in real time. If the system exceeds the set safety process window, it will issue an early warning or shut down to avoid batch defects. This is equivalent to setting up a quality firewall for the production of high-priced products such as transparent cards.

3. Intelligent identification system for transparent materials and sorting function of die-cutting machine

Multi-source triggering, high-precision positioning and sorting: To facilitate the positioning of transparent materials, the equipment provides a variety of options:

-

High-contrast vision system: through the ring light source of a specific wavelength and a high-resolution industrial camera, it captures the tiny thickness changes or internal texture of transparent materials so as to realise the precise positioning of completely transparent materials.

-

Mechanical pre-alignment and data stream docking: It can be connected to the previous printing or laser coding equipment. Then, the mechanical positioning hole information on the edge of the material can be directly read, or the digital registration coordinate data can be received to achieve perfect positioning.

-

Intelligent sorting trigger: The sorting logic can use the pattern difference of visual recognition or use an RFID chip, invisible code information, or the simple batch signal added in the previous step to realise fully automatic and very accurate classification output.

-

Non-destructive conveying and collection: From the die-cutting station to the sorting station and then to the stacking station, the entire conveying path has no sharp edges and corners, and the contact surface is made of soft materials such as silicone and Teflon coating. High-end configurations can use air-floating conveyor tables, where the cards do not touch the conveyor table surface and move on the air film. This completely eliminates the risk of scratching the surface. To ensure the edges and surfaces of the finished card stack are perfect, the card stacker is designed with anti-static and cushioning features.

4. Allows modular growth and the connection of complex process chains

Transparent cards are often used in hot stamping, screen printing, laminating and other processes. The integration of the process was considered in the initial design of the equipment.

-

Standardised online interface: with a mechanical docking platform and a single electrical communication protocol (such as EtherCAT), it can be easily docked with the front-end high-speed hot stamping machine or the back-end automatic packaging machine to form an automated production line of "hot stamping-die cutting-sorting-packaging". It solves the problem of quality control and efficiency loss caused by multiple loading and unloading of cards in the multi-process production process of transparent cards.

-

Quick mould change and multi-function expansion: The patented quick clamping system and the central database controlling mould parameters make the replacement of card-type moulds very fast. The machine's powerful punching capacity and precise platform also enable it to accurately process thicker transparent acrylic sheets, composite plastic sheets and other materials. This gives manufacturers the opportunity to grow their business.

5.Parameters of transparent card die-cutting machine

Power supply |

AC 380V/50 HZ |

Sheet format |

Max. (L*W) 1000*700MM

Min. (L*W) 550*450MM

|

Total power |

10KW |

Control |

PLC control + Servo system |

Air source |

6 kg/cm2 |

Operators needed |

1 |

Air consumption |

Approx. 80L/min |

Dimension |

L2800*W1750*H1850MM |

Punching pressure |

2T-6T |

Drive |

Servo system |

Weight |

Approx. 2000KG |

Punched card size |

Max. 140*140MM

Min. 54*54MM

|

Punching accuracy |

±0.05mm |

Productivity |

1200 Sheets/H |

Applicable card materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

6.Conclusion: Setting a new standard for precise die-cutting of transparent cards

The transparent card die-cutting machine is based on the concept of "precision moulding of transparent cards" and combines deep material processing knowledge with cutting-edge electromechanical technology. It abandons the idea of being as versatile as possible but focuses on being the best in its own field. For any manufacturer in the world who cares about the quality of transparent card products, is very worried about production fluctuations, or wants to develop a high-end transparent card market, purchasing this dedicated equipment is a way to gain a competitive advantage by solving the biggest problems in the process. It not only makes one process better but also makes the final product more attractive to customers and more valuable to the brand by ensuring perfect edges and a good overall appearance of the product. As transparent cards become more and more popular as high-end identification and collection carriers, the equipment is the most important and trustworthy partner for manufacturers who want to turn new ideas into perfect reality.