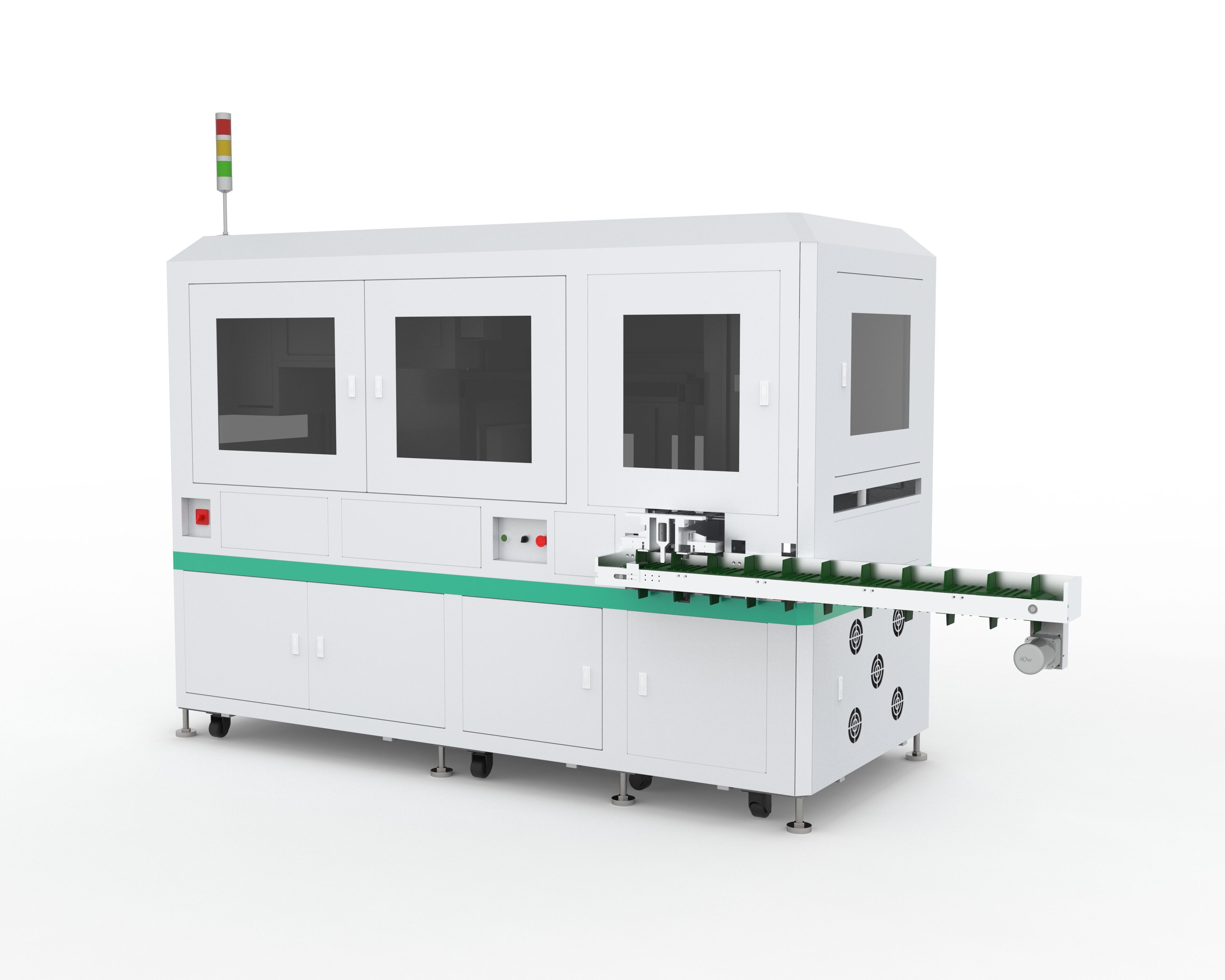

For the manufacturing and packaging industries, precision and versatility are paramount. Dry and wet die-cutting machines are among the few pieces of equipment tailored to meet such needs. This robust equipment facilitates the processing of dry sheets and the die-cutting of sheets, hangers, and jigsaw cards and is used to cut paper, cardboard, film, and non-woven fabrics.

One of the core features of the dry sheet cutting equipment is therefore the ease with which the operating mode can be switched. The machine makes no compromises in terms of speed, and the quality of the cut dry sheets is the only decisive criterion. The equipment does not restrict the thickness and type of the materials used, which can be dry non-woven fabrics, cardboard, and paper. The machine makes no compromises in terms of speed, and the quality of the cut dry sheets is the only decisive criterion.

For entities in the packaging, printing, and consumer goods industries, purchasing a high-quality die-cutting machine is a matter of achieving production goals and meeting the requirements of different industries. The fact that it is intuitive to operate and requires little maintenance makes it a value-for-money choice for large factories and small production units.

Investing in new technology can significantly improve delivery times, product quality, and international market position. The potential of dry and wet metal sheet die-cutting machines to improve manufacturing processes is worth exploring.