Considering the fast-moving children’s book industry today, readers are looking for soft touch finishes, playful interactive bits and even lift-the-flap panels. Of all the types of children’s reading material, those with pictures hidden beneath flaps are the most popular as they transform calm storytelling sessions into miniature adventures alongside treasure hunts. The real surprise, though, lives between the pages; it comes from well-planned production work, especially the precise die cuts that give each sheet its hidden pop. Wentong machinery & Equipment Co., led on the inner page die cutting machine industry for ease of use and helps with modern publishing with precision and high efficiency.

There is a global resurgence by parents, teachers and even caregivers who are seeking printed books for the youngest in their households. These simple books fulfill parents’ desires for screen-free activities that bring the family together not only as a source of fun but also teaches valuable skills. The fine motor functions sharpen through lifting, tugging and peeking at the flaps which aid problem solving, promote early preschool reading readiness and develops independent thinking while encouraging early literacy skills.

But making these books isn’t as simple as it looks. Each flap or tab must be meticulously sliced so that each cut is pristine and seamlessly aligned with the images – this is so that the tab can be opened without obstruction and withstand the excited pulling from children.

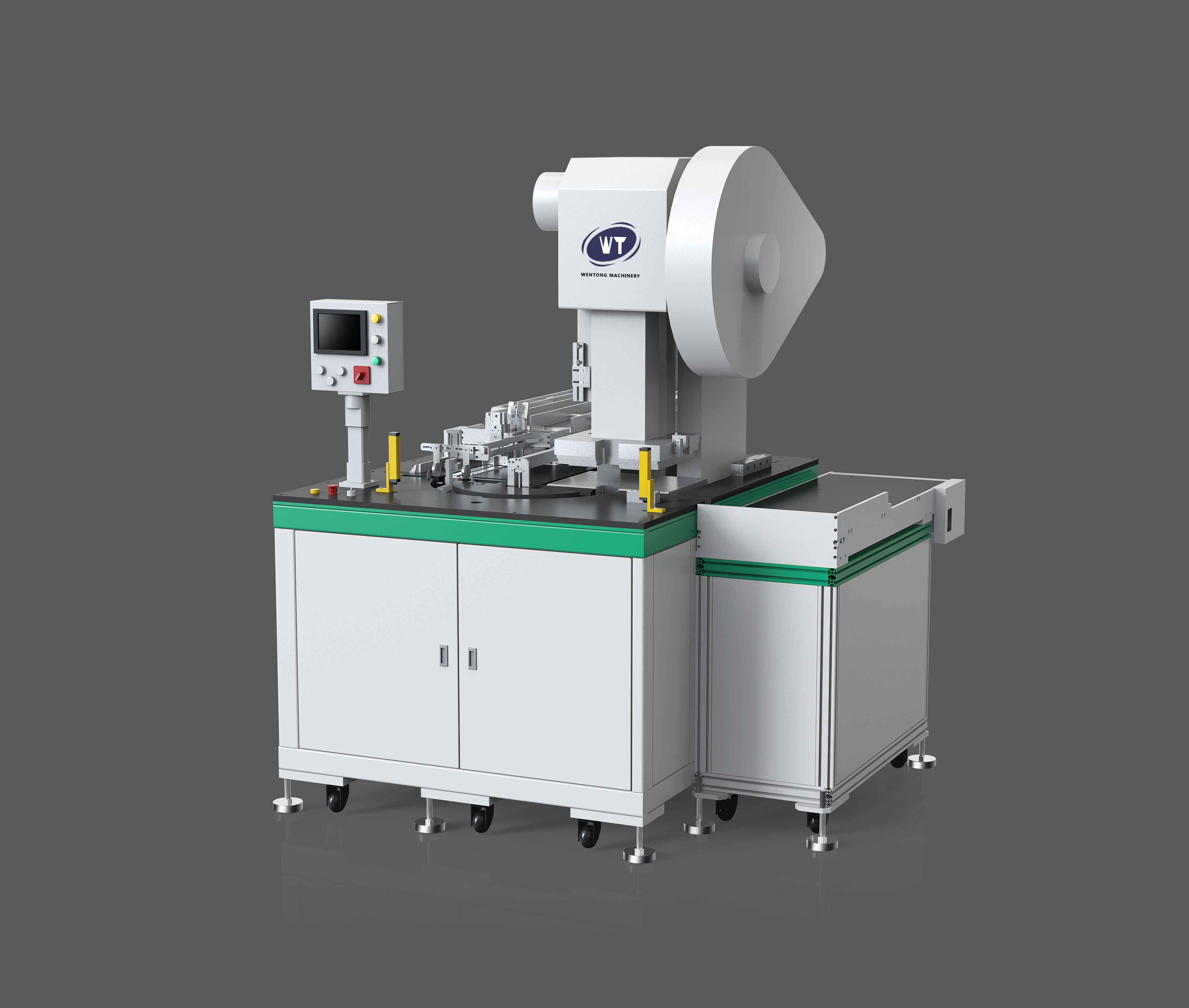

This is where Wentong’s book inner page die cutting machine demonstrates its core strengths:

In a production environment where time is money, and quality is reputation, Wentong provides both reliability and efficiency.

It has been observed that die-cutting machines do not operate as impeccably as needed with modern age children’s books. Regrettably, it has been observed that modern machines do not rise to the occasion. However, Wentong Machinery has tailored its inner page die cutting solution to the cutting edge of the market, and the details manifest sophistication.any conventional die-cutting machines fall short in handling the intricacies required for modern children’s books. Wentong Machinery, however, has specifically engineered its inner page die cutting solution to address this niche market's nuances:

Its simple touchscreen guides operators at any skill level, speeding training and reducing costly mistakes on the shop floor.

Books for Children have evolved impressively beyond boxed shaped pages and simplistic designs. Contemporary publishers are now playing with elaborate multi-flap structures, die-cut silhouettes, pull tabs, embedded pages, complex multi-sensory pages, intricate pop-up pages and more. This begs the question: will production machinery be able to meet such ambitious level of creativity?

With Wentong’s inner page die cutting machine, this answer becomes a resounding yes.

Here’s how the machine is ready for the future:

Hungry for new ideas, strong interaction, and flawless finish, todays publishers and printers see Wentongs inner-page die-cutter as their essential production partner. It lets designers dream big yet keeps speed high and quality rock-solid. Whether you run a mega house that wants to crank out millions of flaps or a small shop play-testing the next picture-book trend, Wentong has the cutting gear you can lean on.

As kids publishing keeps changing, one truth stays bright: tomorrows stories will involve the reader at every turn, and Wentong Machinery is ready to slice that road forward-one flap at a time.