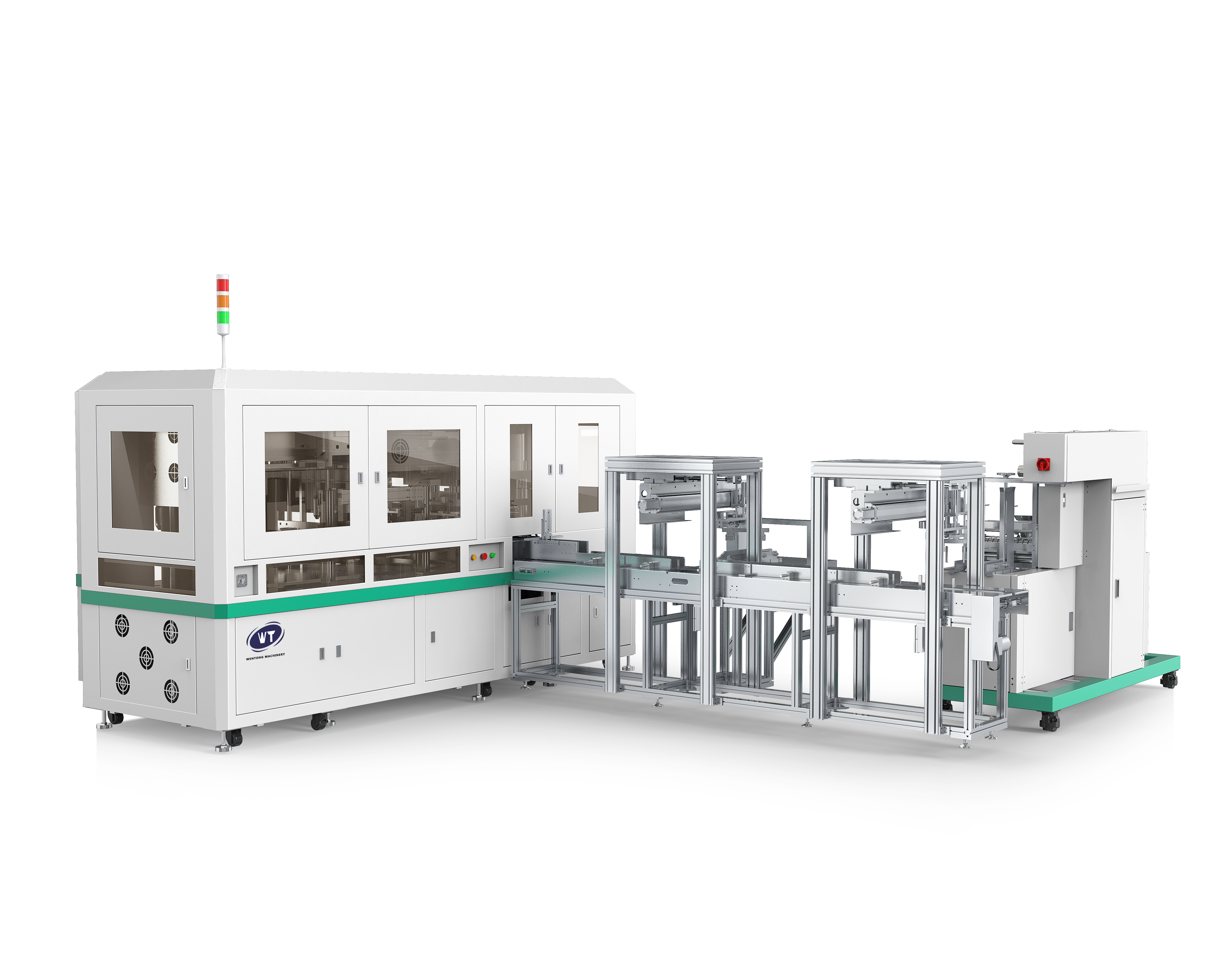

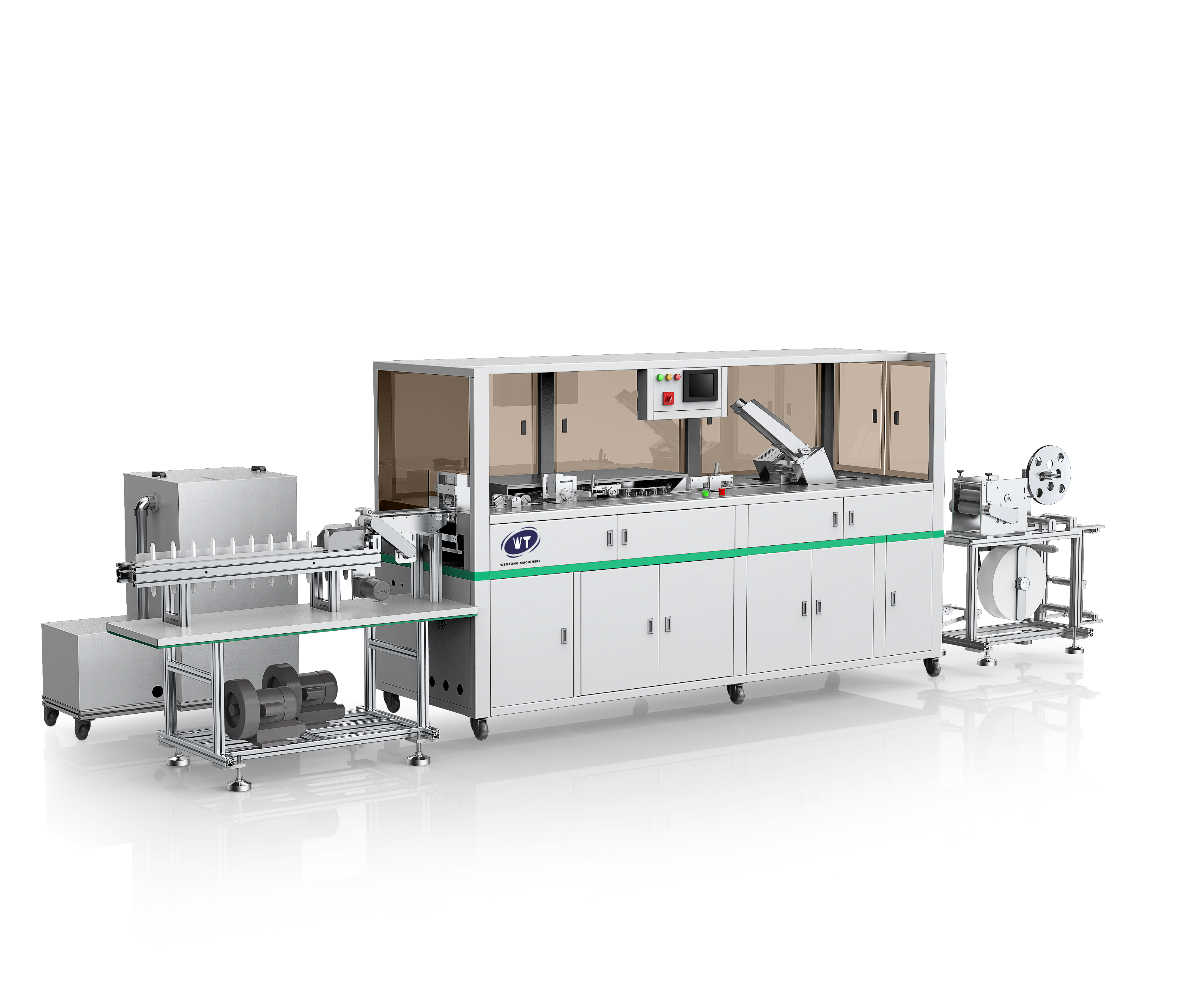

Wentong Machinery’s card packaging machines are engineered to streamline the final stage of card production, offering reliable solutions for sorting, stacking, and wrapping cards into retail-ready packages. These machines address the need for efficient post-production handling, reducing labor costs and improving packaging consistency. The automatic card stacking and packaging machine, such as the WT-CPM series, uses vacuum suction cups to neatly align cards into stacks of specified quantities (e.g., 50 or 100 pieces per stack), with a precision sensor that detects misaligned cards and triggers automatic repositioning. The wrapping module can be configured for different packaging types, including cellophane overwrapping, heat shrink wrapping, or box insertion, with adjustable film tension and sealing temperature controls to accommodate various materials. For added functionality, some models integrate labeling systems that apply product information or barcodes directly to the packages, while others include quality inspection cameras that check for printing defects before packaging. Wentong’s card packaging machines operate at speeds of up to 150 stacks per hour, with a compact footprint that fits into existing production lines. The stainless steel construction and easy-to-clean surfaces make these machines suitable for hygienic environments, while remote monitoring capabilities allow managers to track production metrics and schedule maintenance remotely.