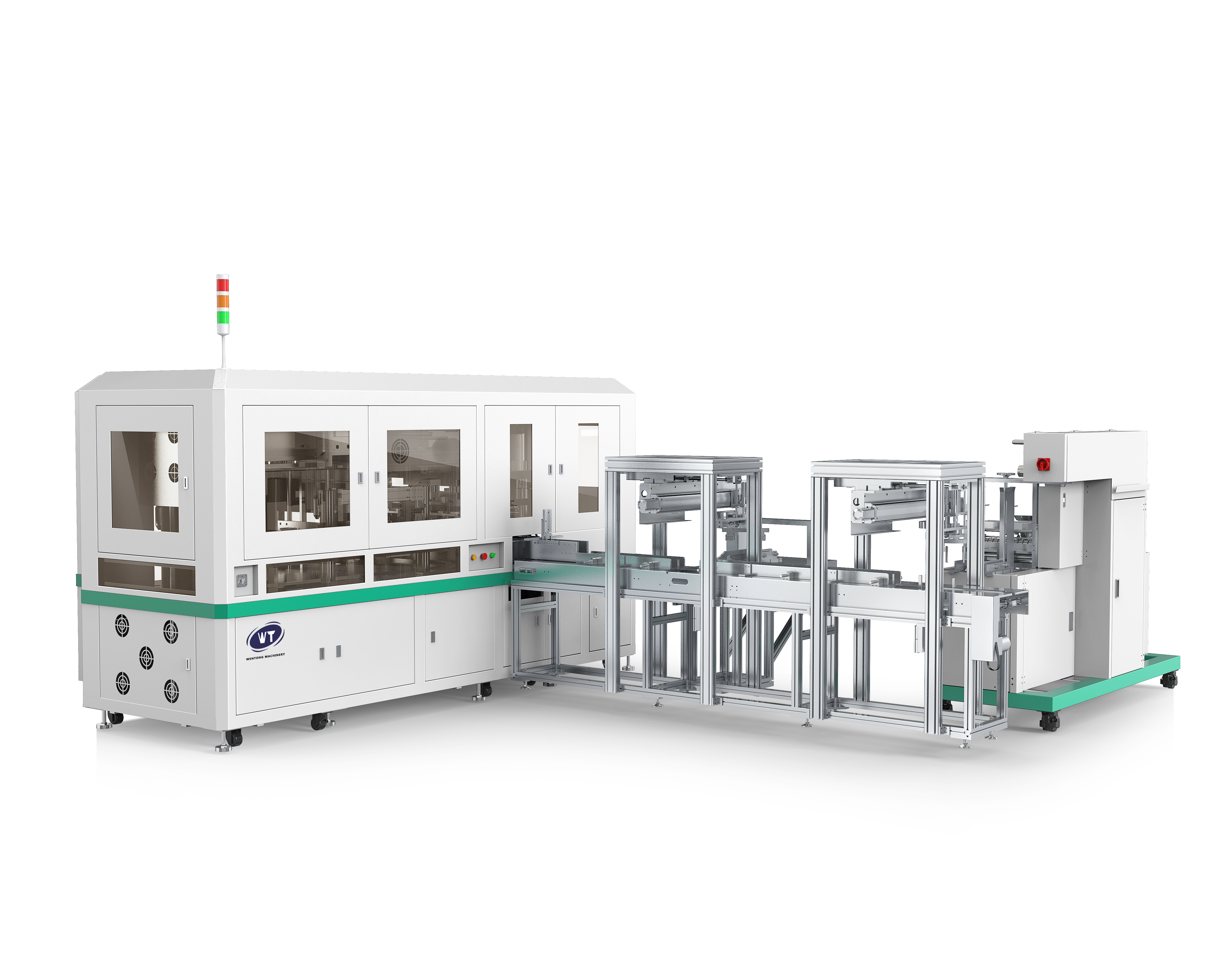

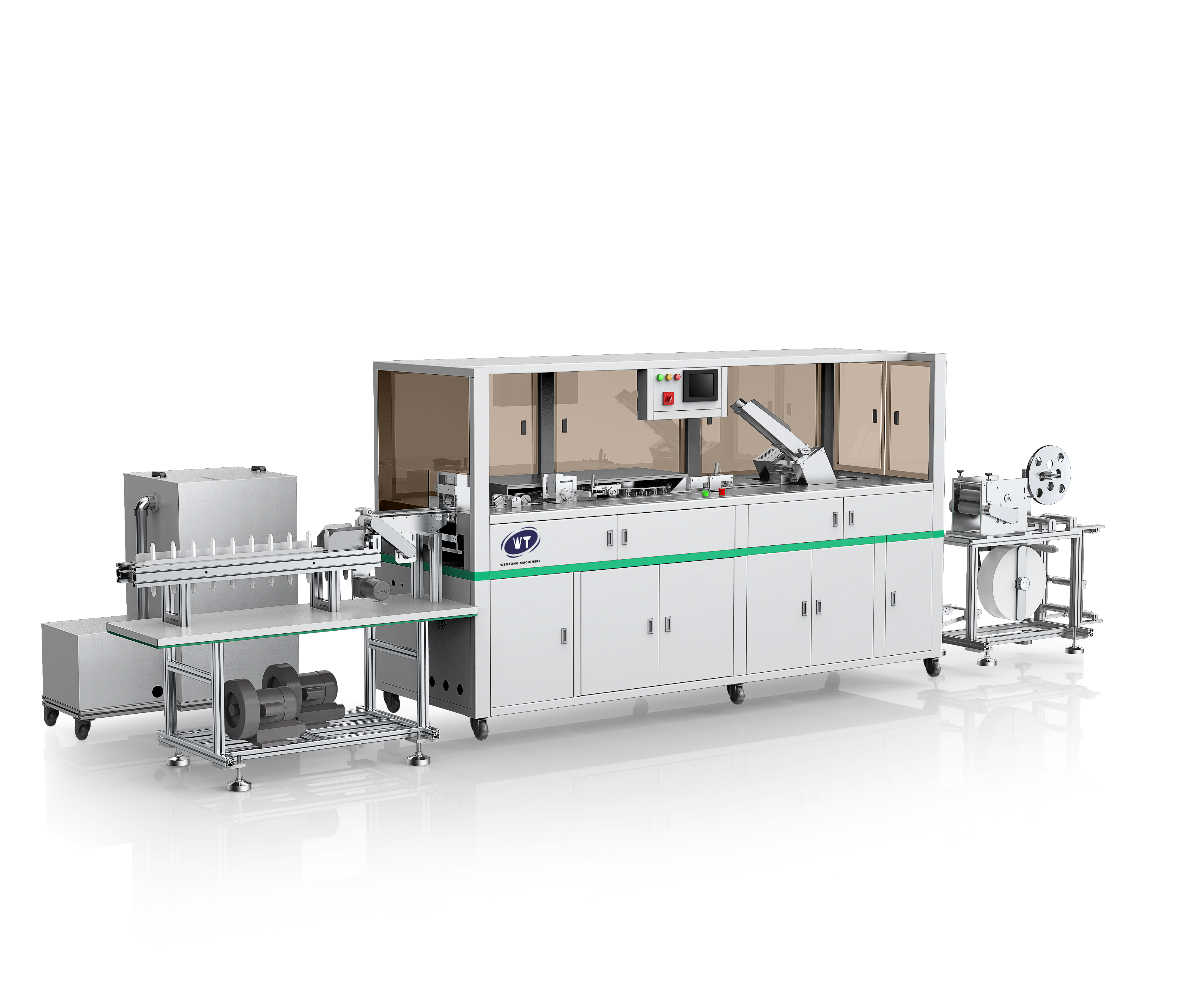

Shenzhen Wentong Machinery Co., Ltd. designs card trimming machines that combine precision cutting with robust durability, catering to the printing and packaging industry’s need for clean, uniform card edges. These machines are engineered with high-precision blades made from hardened tungsten steel, capable of maintaining sharpness through 500,000+ cutting cycles, ensuring consistent trim quality for materials ranging from 80gsm paper to 3mm thick cardstock. The automatic feeding system of Wentong’s trimming machines, such as the WT-CTM series, features vacuum suction belts that align sheets within ±0.3mm accuracy, minimizing waste from miscuts. Operators can adjust cutting parameters via a touch-screen interface, enabling quick setup for different card sizes—from standard business cards (85x55mm) to custom-shaped designs. Safety is prioritized with infrared sensors that halt operation if hands enter the cutting zone, while a built-in dust extraction system keeps the work area clean. The machine’s heavy-duty cast iron base reduces vibration during high-speed cutting (up to 30 sheets per minute), ensuring long-term stability. Wentong’s card trimming machines also support special functions like bevel cutting and batch counting, making them versatile for both mass production and boutique printing needs.