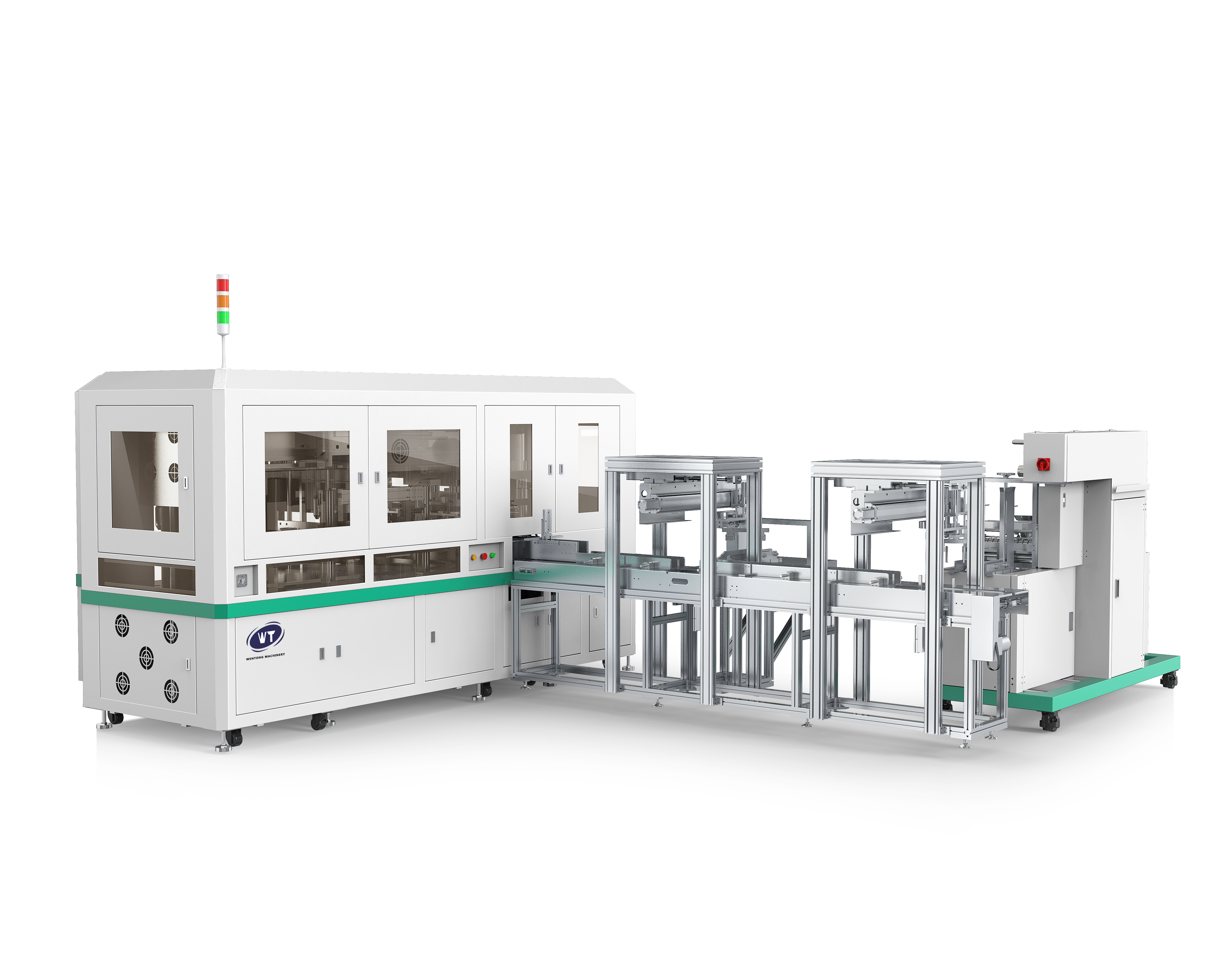

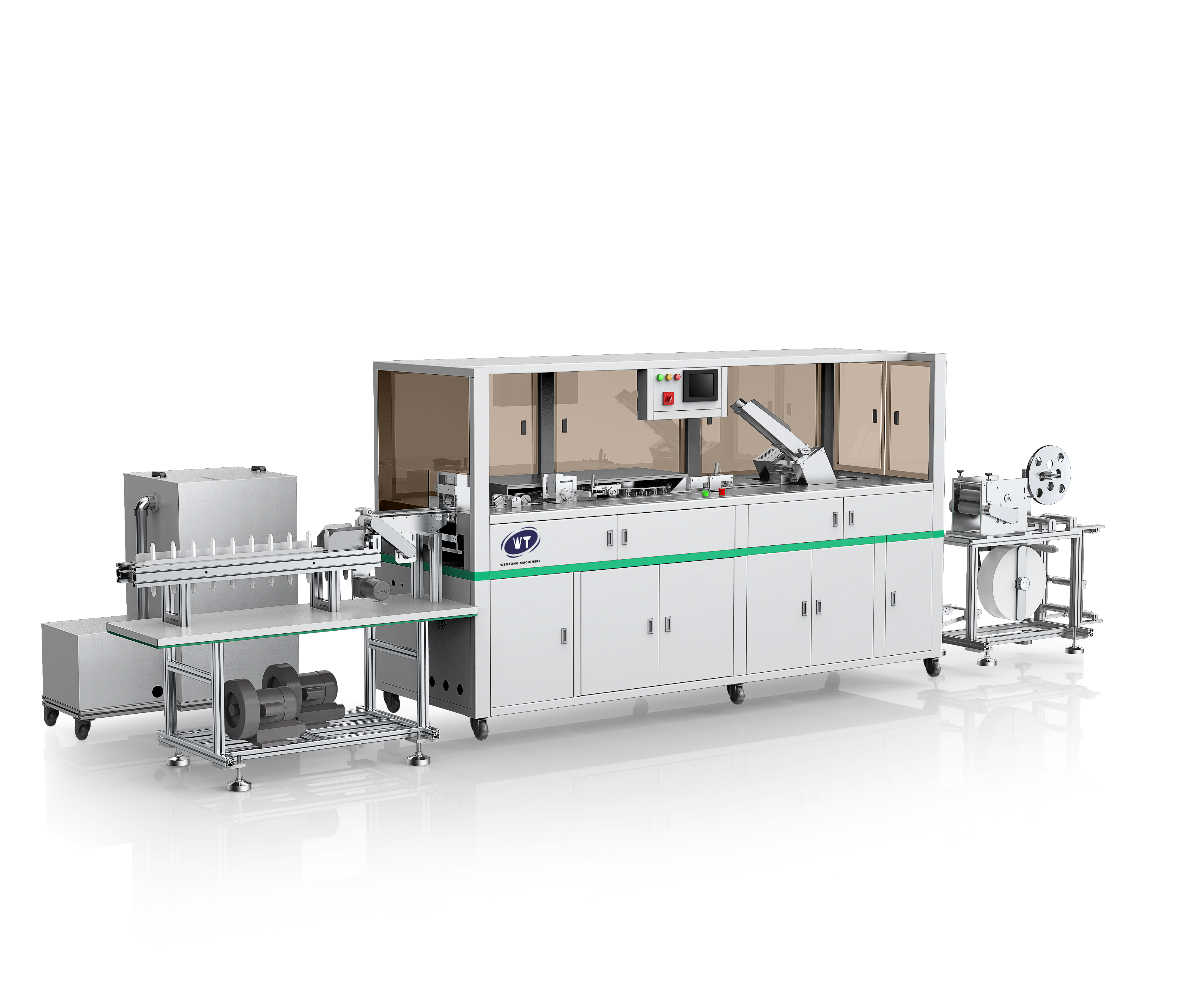

Dependable and Resilient Construction for Lasting Dependability

Card machine purchases are a step towards achieving reliability. Ensuring longevity, these machines are constructed from first-rate materials, carefully crafted parts, and are designed to endure the rigors of heavy use in demanding production settings. Supporting smooth operations, durable mechanical and electronic components are designed to function seamlessly for long periods, while sturdy frames supply stability. In busy card-production factories where machines are used on a daily, multi-hour basis, these machines offer long-lasting dependability and reduce maintenance requirements. This helps avoid expensive repairs and guarantees seamless production, allowing businesses to depend on the machines for meeting production deadlines. With proper servicing, these card machines will elegantly fulfill your card-making requirements for years and form a dependable foundation for your business expansion.