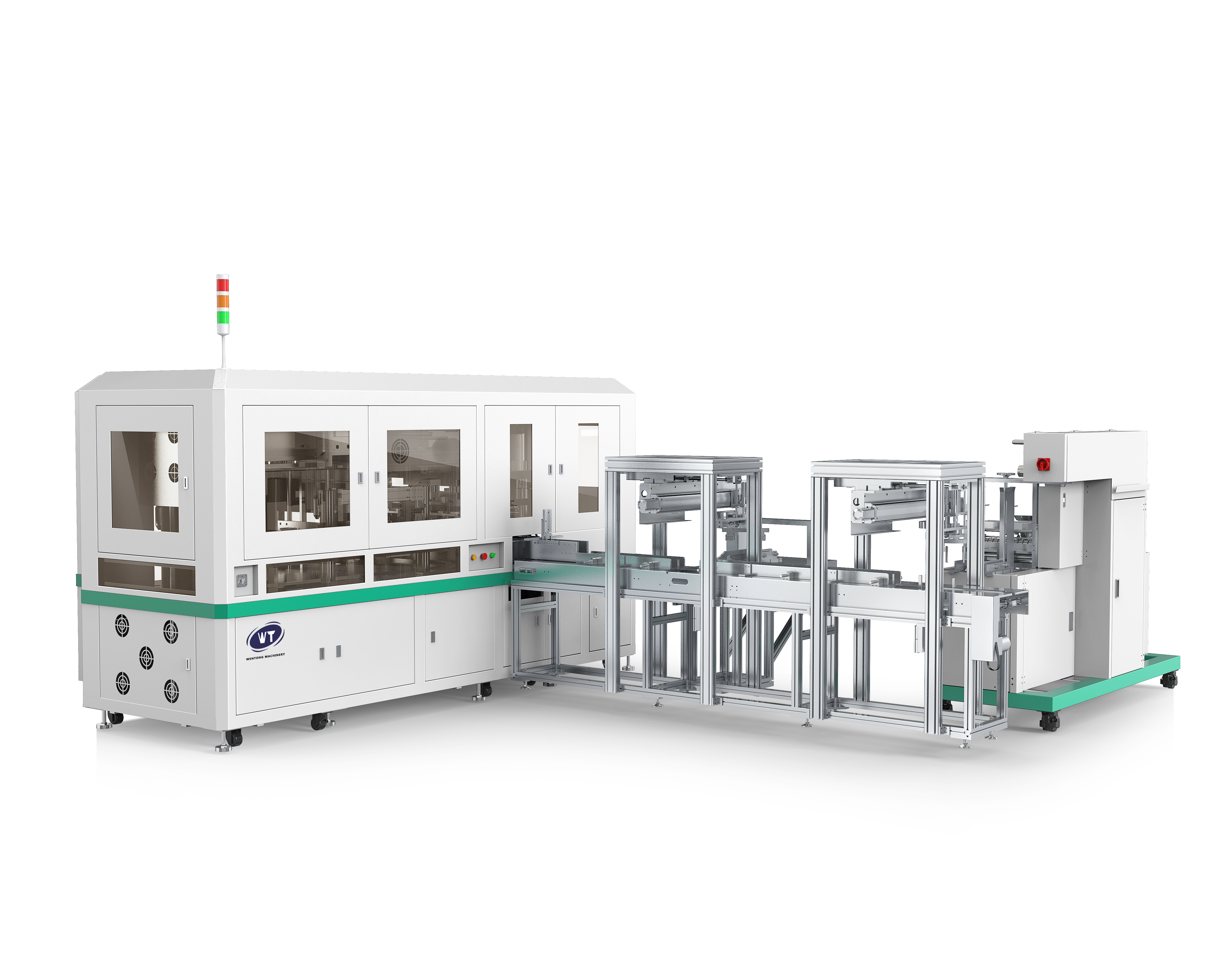

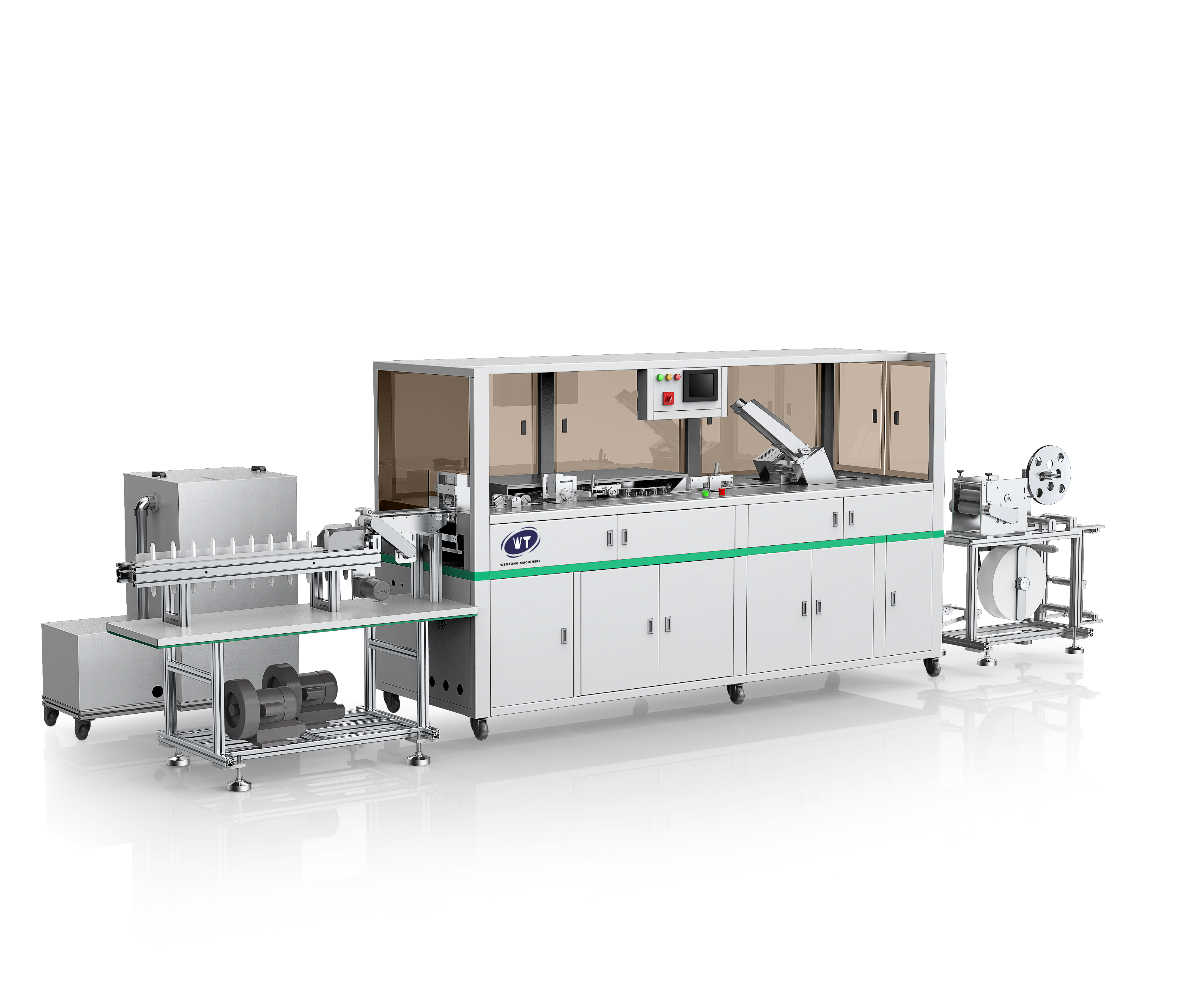

Multifunctional for All-Inclusive Card Solutions

The primary selling point for our card machines is their multifunctionality which ensures all facets of card production are adequately serviced. These machines can cut cards, print them, embossthem all in the same place. In a card producing company, one machine is able to cut card materials of various thicknesses, print images and text including logo or arrangement, emboss logos or reliefs, and laminate the cards. There are some jobs for which you do not need to purchase a number of different machines. autonomy from the card machines designed. When it comes to production, our card machines offer dependable convenience and efficiency for the card making processes, whether simple business cards or complex ID cards with a multitude of security features.