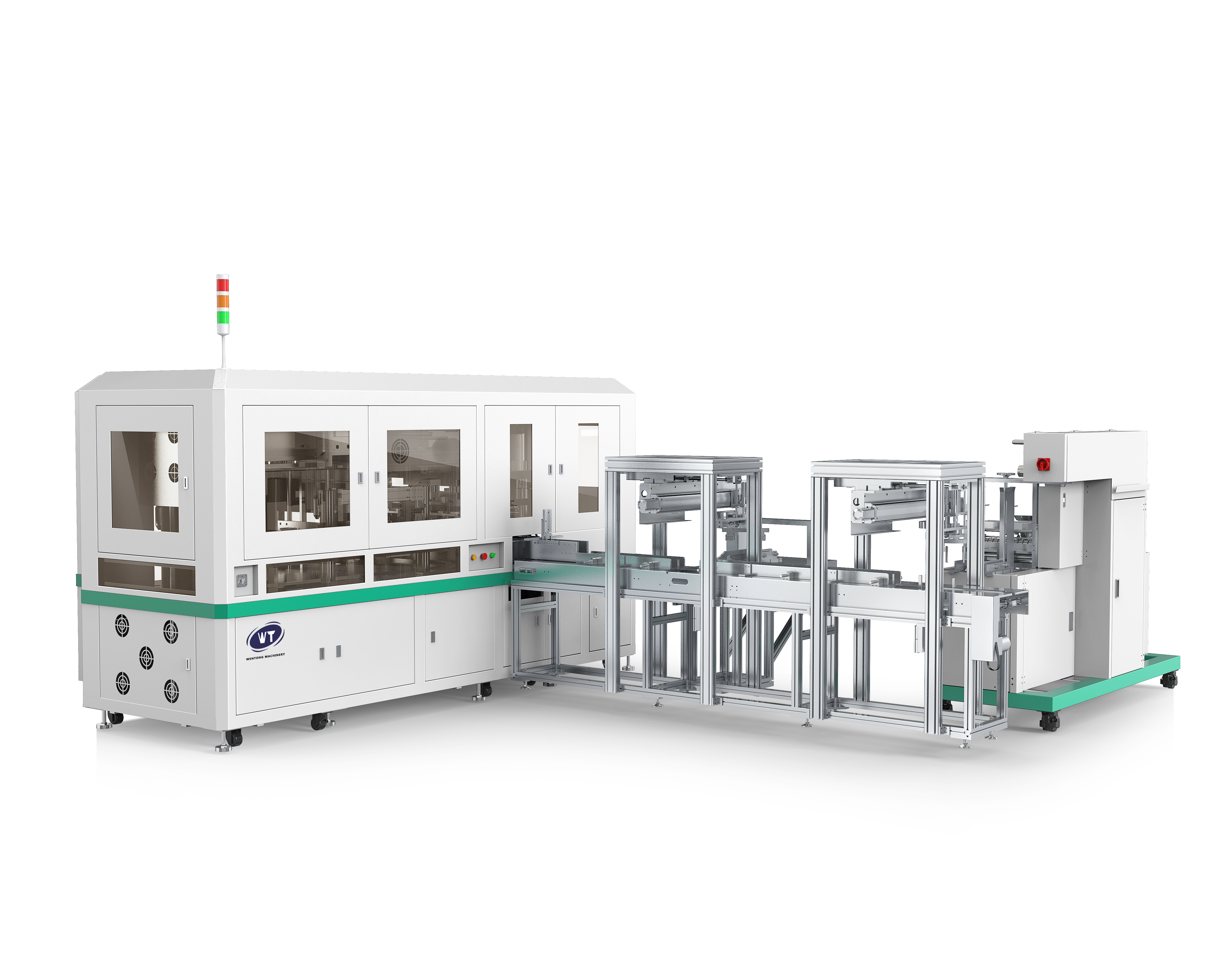

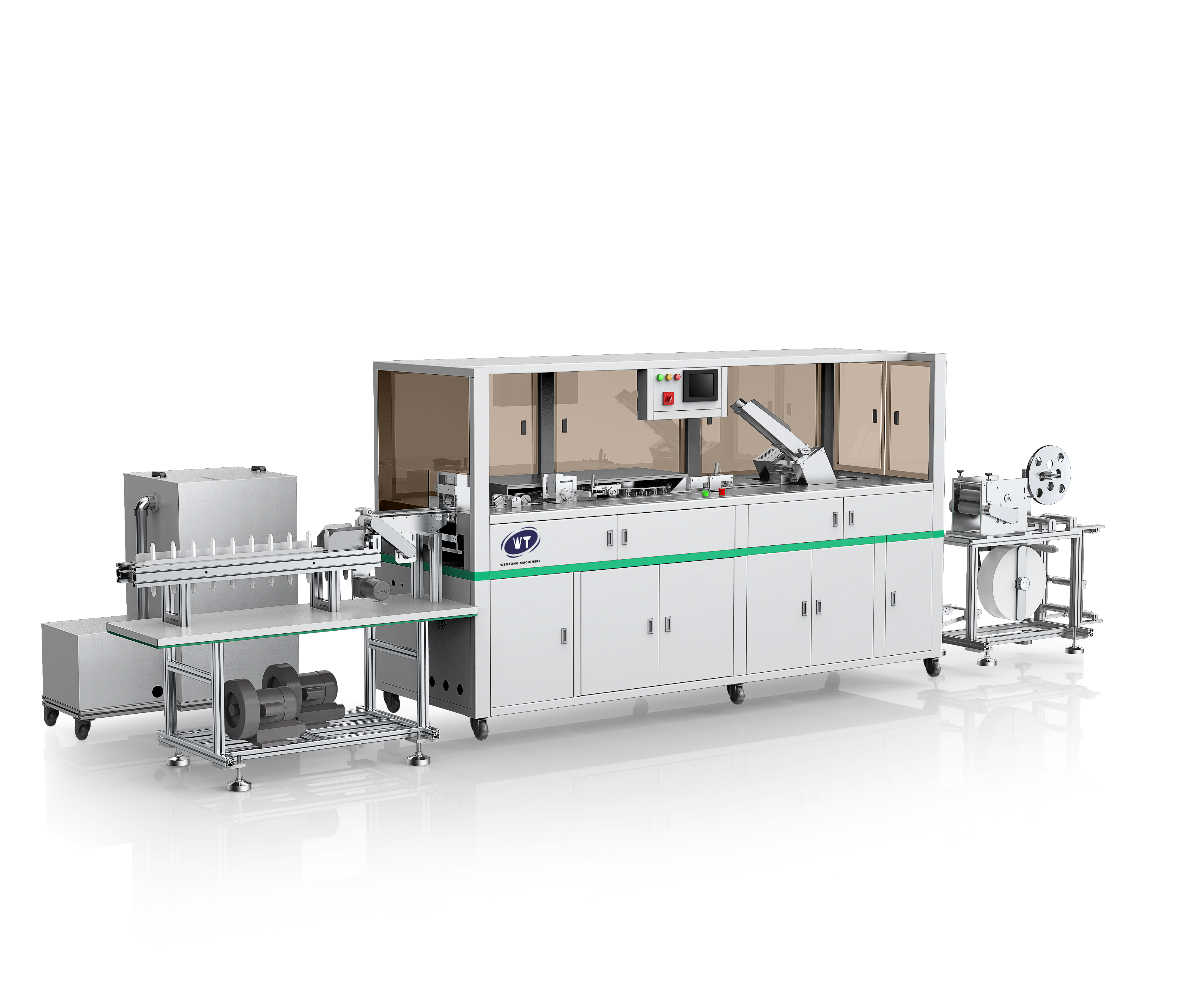

The systems we provide are the latest in innovation in magnetic card machines. Their encoding and personalization capabilities let you create high quality magnetic cards from scratch. Everything is manageable with these machines which revolve from ID cards tequiring access information encoding to debit cards that require payment data addition and even membership cards customization. Their data-writing algorithms ensure accuracy and reliability in card encoding which is completed though measurement checks with head alignment.