Les cartes intelligentes (telles que les cartes bancaires, les cartes de transport, les badges d'accès, les cartes d'identité, etc.) et les cartes haut de gamme pour jeux (telles que les cartes à collectionner, les cartes de jeux de société, les cartes à jouer à collectionner, les cartes d'animation, etc.) sont des supports alliant technologie et art. Avec la croissance rapide des marchés mondiaux du paiement numérique, de la reconnaissance d'identité et de la consommation ludique, les normes de production et de fabrication deviennent de plus en plus strictes. La convergence de ces deux secteurs impose des exigences extrêmement élevées en matière de précision, de durabilité, de sécurité et d'unicité des produits. Dans cet étape clé de fabrication, la machine de découpe par emporte-pièce a évolué d'un simple outil de coupe vers une plateforme de production intégrant mécanique de précision, commande numérique et automatisation intelligente. Cet article détaillera comment machines de découpe par matrices résoudre de manière créative les principaux problèmes liés à la production de cartes intelligentes et de cartes de jeu. Il présentera également ses applications les plus avancées et les meilleures pratiques du secteur.

L'implantation de puces, le laminage d'antennes, la composition multicouche, le moulage de précision et d'autres étapes font tous partie de la fabrication des cartes à puce. Le processus est complexe et comporte trois grands problèmes :

Les microprocesseurs (CI) et les structures d'antenne à l'intérieur de la carte sont très précis et facilement endommageables. Lors du processus d'estampage, une concentration de contraintes, un écart de précision, des bavures sur les bords ou d'autres conditions peuvent provoquer des micro-dégradations du circuit, entraînant une défaillance du fonctionnement et un grand nombre de rebuts.

Conçu pour une utilisation intensive au quotidien. La délaminage des bords, les bavures ou les microfissures n'accélèlent pas seulement les dommages physiques, mais rendent également plus difficile la lecture et l'écriture sécurisées des données. Les produits doivent strictement respecter des normes internationales telles que l'ISO/IEC 7810 afin de garantir leurs dimensions, bords et durabilité.

Les cartes à puce modernes sont principalement fabriquées à partir de matériaux composites multicouches, tels que le PVC, le PET, le PC ou des matériaux biosourcés respectueux de l'environnement. Le processus d'emboutissage doit être propre, rapide et sans déchets.

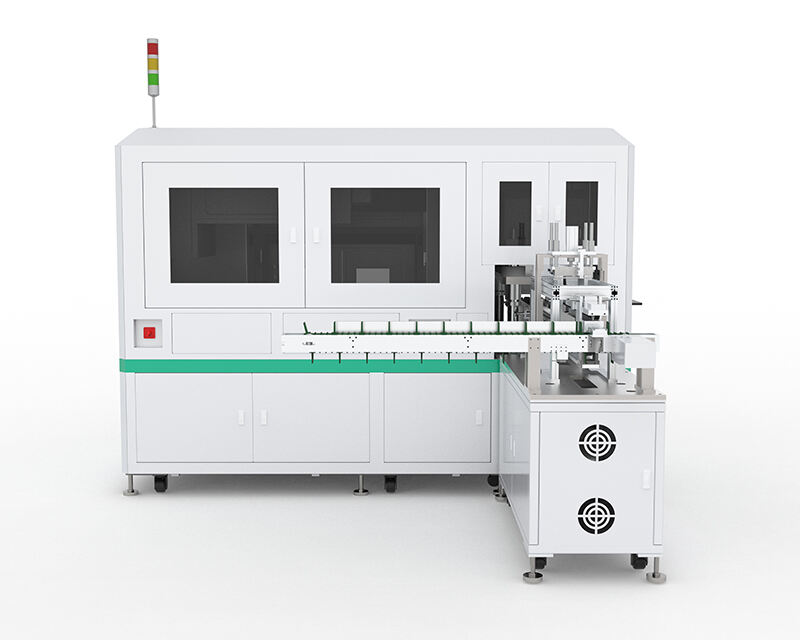

Face aux problèmes susmentionnés, les technologies modernes haute performance machines de découpe par matrices offrent une solution systématique dans une optique de mécanique des ingénieurs :

La sécurité commence par l'estampage de précision et la technologie sans bavures, dont le cœur est constitué par la conception d'un châssis monobloc à ultra-haute rigidité et un système de guidage linéaire de précision. Grâce à l'automatisation à entraînement servo haute puissance de 7,5 kW ou plus, il permet une commande en boucle fermée précise au millième de seconde de la pression, de la vitesse et de la course. Le couteau de découpe précis garantit une surface de coupe aussi lisse qu'un miroir, sans bavures ni délaminage lors de la découpe de matériaux composites multicouches. Cela est essentiel pour préserver la zone du module électronique en toute sécurité et maintient les taux de rebut fonctionnel en dessous de 0,15 %, bien en deçà de la moyenne industrielle.

l'appareil emboutit des textures ou reliefs clairs et durables à la surface de la carte ou dans des zones spécifiques (comme les bandes de signature, le braille, etc.) grâce à une pression réglable et une profondeur de découpe par empreinte. Cela confère à la carte une texture unique et augmente sa durabilité. Ce procédé non seulement améliore l'aspect professionnel du produit et le rend plus difficile à falsifier, mais améliote également grandement la résistance à la fatigue par flexion de la carte en éliminant les défauts de contrainte au niveau des bords. Des essais ont montré que la carte peut être pliée plus de 50 % de fois supplémentaires, prolongeant considérablement sa durée de vie.

Un système intégré de haute précision optique ou mécanique d'alimentation garantit que l'erreur de positionnement de chaque carte est inférieure à ±0,1 mm. Le dispositif efficace de débourrage et d'élimination composite permet de séparer et d'évacuer rapidement les déchets de cadre, de maintenir la zone de travail propre et de faire atteindre au taux d'utilisation du support de carte une valeur proche du maximum théorique. Cela est essentiel pour la production à grande échelle, car cela permet d'économiser temps et argent.

La valeur principale des cartes de jeu et des cartes à collectionner réside dans leur aspect artistique, leur sensation unique et l'expérience émotionnelle qu'elles procurent. De plus en plus de cartes de jeu et de collection font l'objet de personnalisations poussées et de techniques variées :

Le marché a une forte demande pour la découpe de formes spéciales, telles que des formes rondes, en bouclier, des contours de caractères, des figures géométriques irrégulières, voire des creusages de précision internes. Les moules traditionnels sont lents à modifier et coûteux. La solution moderne consiste à utiliser des moules légers en bois de haute précision ou des gabarits magnétiques. Le temps de changement de moule peut être réduit à 2-3 minutes, permettant une production personnalisée en petites séries, multi-séries et à itération rapide. C'est tout simplement une bénédiction pour les besoins de « mode rapide » et de diffusion limitée sur le marché des cartes.

Le gaufrage (également connu sous le nom de dorure à chaud) est désormais un moyen courant pour que les cartes de jeu haut de gamme se démarquent, en raison de leur rareté, de leur identité de marque ou de motifs uniques. Grâce à un système de commande servo unifié et avancé machines de découpe par matrices peut facilement ajouter une unité de marquage à chaud entièrement automatique. Cela permet d'aligner parfaitement le motif de marquage à chaud avec le contour de découpe (généralement avec une erreur inférieure à ±0,1 mm). Ce mode « une seule alimentation pour réaliser plusieurs processus » améliore non seulement l'efficacité, mais garantit également la cohérence de l'effet décoratif de chaque carte, augmentant ainsi considérablement la valeur de collection et le niveau esthétique du produit.

La surveillance de l'apparence dans la gestion des commandes, des cartes de série, des cartes à tirage aléatoire et des cartes codées est très importante. Vous pouvez ajouter des méthodes de collecte personnalisées très flexibles pour l'appareil :

Triage : Assurer que les cartes portant des numéros de série ou des motifs répétés soient dans l'ordre de leur production afin de faciliter l'emballage.

Tri par catégorie : Le dispositif de tri automatique trie les cartes dans différents emplacements de collecte en fonction du motif, de la rareté, de la couleur et d'autres facteurs relatifs aux cartes. Cela est réalisé grâce à un système d'inspection visuelle en ligne ou à un programme prédéfini. Cela rend l'étape suivante de tri manuel moins coûteuse, moins sujette aux erreurs et permet une automatisation complète du processus de production.

La meilleure façon d'améliorer la compétitivité globale consiste à permettre aux principaux fabricants de cartes de combiner les fonctions avancées de la machine de découpage par emboutissage :

Lorsque le marché présente des besoins différents, la clé pour obtenir un bon retour sur investissement est de disposer d'équipements capables de réaliser de nombreuses fonctions. Une machine de découpe bien conçue et à hautes performances peut non seulement changer rapidement les moules et ajuster les paramètres afin de produire parfaitement des cartes intelligentes, des cartes de jeu, des cartes bancaires et des cartes d'animation, mais aussi parfaire efficacement la découpe des livres et des cahiers ainsi que perforer et découper avec précision du papier filtre et des joints industriels. Une seule machine dotée de multiples fonctions offre aux entreprises d'impression et d'emballage une grande flexibilité en matière de capacité de production et leur permet de s'adapter aux évolutions du marché.

Pour créer réellement de la valeur, nous devons comprendre en profondeur les problèmes des clients et les résoudre. Nous fournissons des solutions entièrement personnalisées pour les clients internationaux, en tenant compte de propriétés de matériaux différentes, d'objectifs de capacité de production, de combinaisons de procédés (comme le découpage à l'emporte-pièce + le gaufrage + l'impression de code QR) et d'aménagements d'usine. Ces solutions incluent les essais préliminaires de procédés, la conception et la fabrication de moules, l'intégration de lignes de production automatisées (y compris l'alimentation automatique, le contrôle qualité, l'empilage et l'emballage), ainsi que la formation technique. Les clients peuvent tirer parti de ce modèle de service approfondi afin d'améliorer l'efficacité globale des équipements (OEE) et de réduire le coût total de possession (TCO).

Une technologie mature et une forte automatisation garantissent une qualité stable. L'équipement est entièrement intégré à une plateforme modulaire éprouvée, dotée d'un contrôle servo numérique complet, de capteurs intelligents et d'une interface homme-machine centralisée. L'ensemble du processus, du chargement du rouleau de matière à l'alimentation précise, au découpage dynamique au die, à l'évacuation en temps réel des déchets et à la collecte intelligente du matériau, est automatisé. Cela garantit non seulement la stabilité de l'équipement lors d'une production continue 7x24 heures et réduit le taux de défaillance, mais assure également que chaque lot de produits, qu'il s'agisse de cartes de paiement à échelle de millions ou de milliers de cartes de collection limitée, conserve toujours la plus haute qualité.

Dans des secteurs tels que les cartes à puce et les cartes de jeu, qui allient fabrication de haute précision et conception créative, machines de découpe par matrices sont une percée technologique qui conduit directement l'évolution du secteur. Ces indicateurs clés permettent d'en mesurer la valeur fondamentale :

En matière de qualité et d'efficacité, l'utilisation d'une machine entièrement servomotrice de haute précision pour le découpage par empreinte permet de réduire le taux global de rebut du processus d'estampage, passant d'environ 1 % avec les équipements traditionnels à moins de 0,1 %. En même temps, la vitesse de production augmente en moyenne de 25 % à 40 %. Cela signifie que pour des projets impliquant des dizaines de millions de cartes à puce ou de cartes de jeux populaires, vous pouvez économiser des millions de dollars en coûts de matériaux et livrer les cartes plus rapidement à vos clients.

Machines de découpe par matrices sont les outils les plus importants pour réaliser des découpes de protection sur les puces jusqu'aux modèles artistiques complexes, car ils offrent une grande liberté en matière de conception et de valeur du produit. Ils repoussent directement les limites du design produit, rendant les produits plus sûrs, plus interactifs et plus précieux en tant qu'objets de collection, aidant ainsi les marques à conquérir le marché.

La qualité durable de l'équipement et ses faibles besoins d'entretien font en sorte que l'investissement s'amortira avec le temps. Une seule machine peut accomplir de nombreuses tâches, permettant ainsi une meilleure utilisation des actifs. La fabrication mondiale évolue vers une approche plus allégée et écologique, et l'élimination efficace des déchets ainsi qu'une forte utilisation des matériaux s'inscrivent dans cette tendance.

Avec l'évolution des cartes intelligentes vers la flexibilité, la finesse et l'Internet des objets, ainsi que la demande croissante de matériaux spéciaux tels que l'interaction en réalité augmentée (AR), les métaux et la transparence pour les cartes de jeu, la technologie de machines de découpe par matrices évoluera vers l'ultra-précision, l'intelligence (vision artificielle intégrée avec ajustement en temps réel) et la flexibilité. Pour les fabricants chinois de Shenzhen qui desservent des clients internationaux, continuer à se concentrer sur la fourniture de solutions de découpe technique approfondie, haute stabilité, forte fiabilité, forte personnalisation et interconnexion intelligente constitue non seulement la clé pour répondre aux besoins actuels des clients du secteur de l'imprimerie, mais aussi le pilier stratégique afin de mener conjointement la révolution future de la fabrication de cartes. Grâce à une coopération technique approfondie dont le transfert de savoir est le cœur, cela aide les partenaires mondiaux à bâtir des avantages manufacturiers durables et compétitifs sur un marché fortement concurrentiel.