The global market for collectible cards, smart game cards, high-end poker cards, and anime collectible cards is still growing. The quality, production speed, and ability to meet personalized needs of card products have reached new heights. We released a new generation of high-performance game card die-cutting machine for the global market.

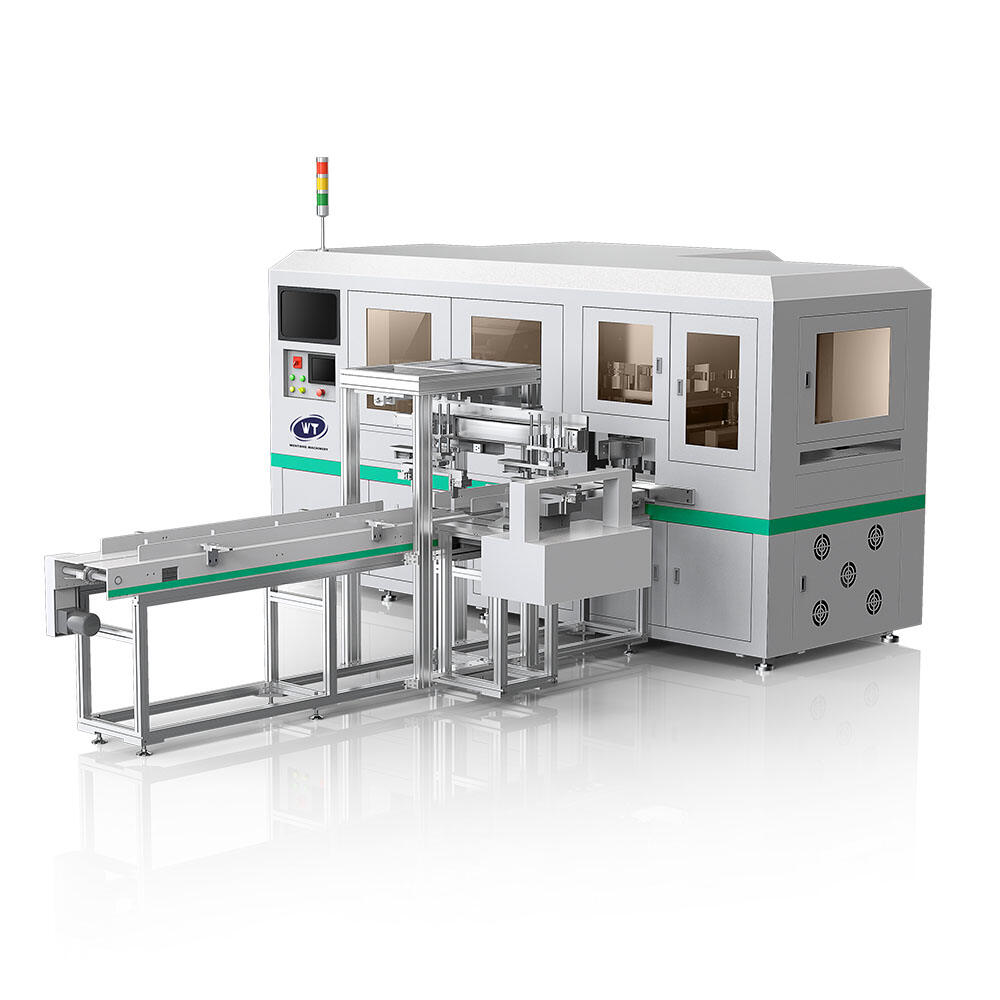

The global market for collectible cards, smart game cards, high-end poker cards, and anime collectible cards is still growing. The quality, production speed, and ability to meet personalized needs of card products have reached new heights. We released a new generation of high-performance game card die-cutting machines for the global market. It is not just a punching machine but a customized production system integrating precision die cutting, texture processing, hot stamping, intelligent automatic sorting, and classification. It is designed to meet the strict requirements of high-end card manufacturers.

The design concept of this poker card die-cutting machine is "accurate, efficient, flexible, and intelligent." It mainly serves the following types of customers around the world:

The feel of the card is the first factor that affects people's use of the card. The machine adopts a special pressure control system and precision pad technology and applies appropriate pressure while cutting the card material. Not only does it complete the cutting, but it also gives the card edge a unique micro-pressure polishing effect, and the overall texture is better. The card edge cut by this machine is smoother and more beautiful than the ordinary die-cut card. This makes the product look more valuable.

The main body of the equipment adopts a high-strength alloy cast iron frame, which is treated with multiple stress reliefs to ensure that it will not be deformed after long-term use under heavy load. The core guide rails, bearings, and other moving parts are all famous international brands. This ensures that the equipment will not have problems such as excessive wear and heat generation even when it is moving XX times per minute (actual data). The mean time between failures (MTBF) is much higher than the industry standard, providing a strong guarantee for customers to always be able to manufacture products.

This die-cutting machine is designed to solve the problem of only one card being able to be made at a time. The equipment can easily handle:

Cards: game cards, smart cards, playing cards, and bank cards.

Paper products: hardcover books and notebook covers are punched into special shapes.

Special materials: Laboratory-grade filter paper and high-density fiberboard are used to manufacture the product with extremely high precision.

This flexibility allows customers to quickly change production lines based on market orders. This allows them to maximize their investment in equipment.

The equipment can include a high-precision hot stamping unit to meet the visual effect requirements of high-end cards. Hot stamping can be performed before and after the die-cutting station, and die-cutting and surface decoration can be completed in one pass. The hot stamping position accuracy can reach ±0.15 mm, which is suitable for hot stamping local logos, text, borders, etc. This makes the product look more expensive and more difficult to copy.

The equipment control system is built on a mature industrial platform that has been tested on thousands of machines worldwide. The human-machine interface (HMI) is easy to use and available in multiple languages. The parameter setting and fault diagnosis are intelligent. The mature process database can store the production parameters of hundreds of products, which can be called with one click, which is convenient and fast. This makes it easier to use and less dependent on skilled technicians.

We know that using the same equipment to handle all problems does not solve all production problems. Therefore, we offer a full range of services, from initial consultation and process testing to customized equipment. We can customize the mold, material collection scheme, and even the whole line layout planning according to the specific card size, material thickness (0.2 mm-1.2 mm), shape (rounded corners, special-shaped holes), and workshop layout of customers.

This is the biggest difference between this equipment and the old die-cutting machine. The built-in high-speed visual recognition system or pre-programmed logic can find and automatically sort and classify the die-cut cards in real time. For example:

When making game cards, you can classify them by rarity and pattern.

During the smart card production process, coded and uncoded cards can be classified.

Take away those products with slight misprints and stains.

This function replaces the time-consuming and error-prone manual sorting work, and the efficiency is increased by more than 70%.

The high-precision reducer is matched with a high-power 7.5 kW high-performance servo motor to provide power for the core of the equipment. This means:

We provide flexible collection methods for the finished products after sorting, and customers can choose according to the production process:

The equipment adopts a patented double elbow lever linkage mechanism to ensure that the die-cutting knife hits the material with the maximum pressure and the most vertical angle. The high-quality die-cutting knife with special grinding technology truly realizes "no waste" cutting. The card edges are free of burrs, wire drawing, and delamination. Smooth and flat. This feature is very important for long-term use of game cards, bank cards, etc. that need to be plugged and unplugged frequently. At the same time, it can prevent burrs so as not to affect the subsequent hot stamping and inkjet coding process.

Power supply |

AC 380V/50 HZ |

Sheet format |

Max. (L*W) 1000*700MM Min. (L*W) 550*450MM |

Total power |

10KW |

Control |

PLC control + Servo system |

Air source |

6 kg/cm2 |

Operators needed |

1 |

Air consumption |

Approx. 80L/min |

Dimension |

L2800*W1750*H1850MM |

Punching pressure |

2T-6T |

Drive |

Servo system |

Weight |

Approx. 2000KG |

Punched card size |

Max. 140*140MM Min. 54*54MM |

Punching accuracy |

±0.05mm |

Productivity |

1200 Sheets/H |

Applicable card materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

ake the standard size (63x88mm) PVC game card as an example. When equipped with an automatic sorting and dealing system, 100,000 cards can be produced per shift (8 hours). Please fill in the actual measured data. Customers can typically recover the cost of the equipment in 12 to 18 months through increased efficiency and reduced waste. This can be achieved by reducing the number of sorting station employees by at least two to three and keeping the rejection rate of finished products below 0.1%.

As the global card market becomes increasingly competitive, basic die-cutting functions are no longer sufficient to gain a competitive advantage. The reason why the Wentong game card die-cutting machine is a forward-looking production solution is that it has a unique card-forming method, precision punching that guarantees no burrs, multiple functions in one machine, and an intelligent core that automatically sorts and sorts cards. It is not only a tool to improve production capacity but also a strategic partner to help customers improve product quality, automate complex production processes, and ultimately make customers more competitive in the global market.

We are located in Shenzhen, China, where the Pearl River Delta has a strong supply chain and R&D ecosystem, which helps us ensure the highest quality of equipment and rapid technological changes. Our engineering team is ready to provide remote and on-site assistance to customers around the world to ensure your production line is always running smoothly. Please feel free to contact our sales team for a personalized solution and demonstration to meet your specific production needs.