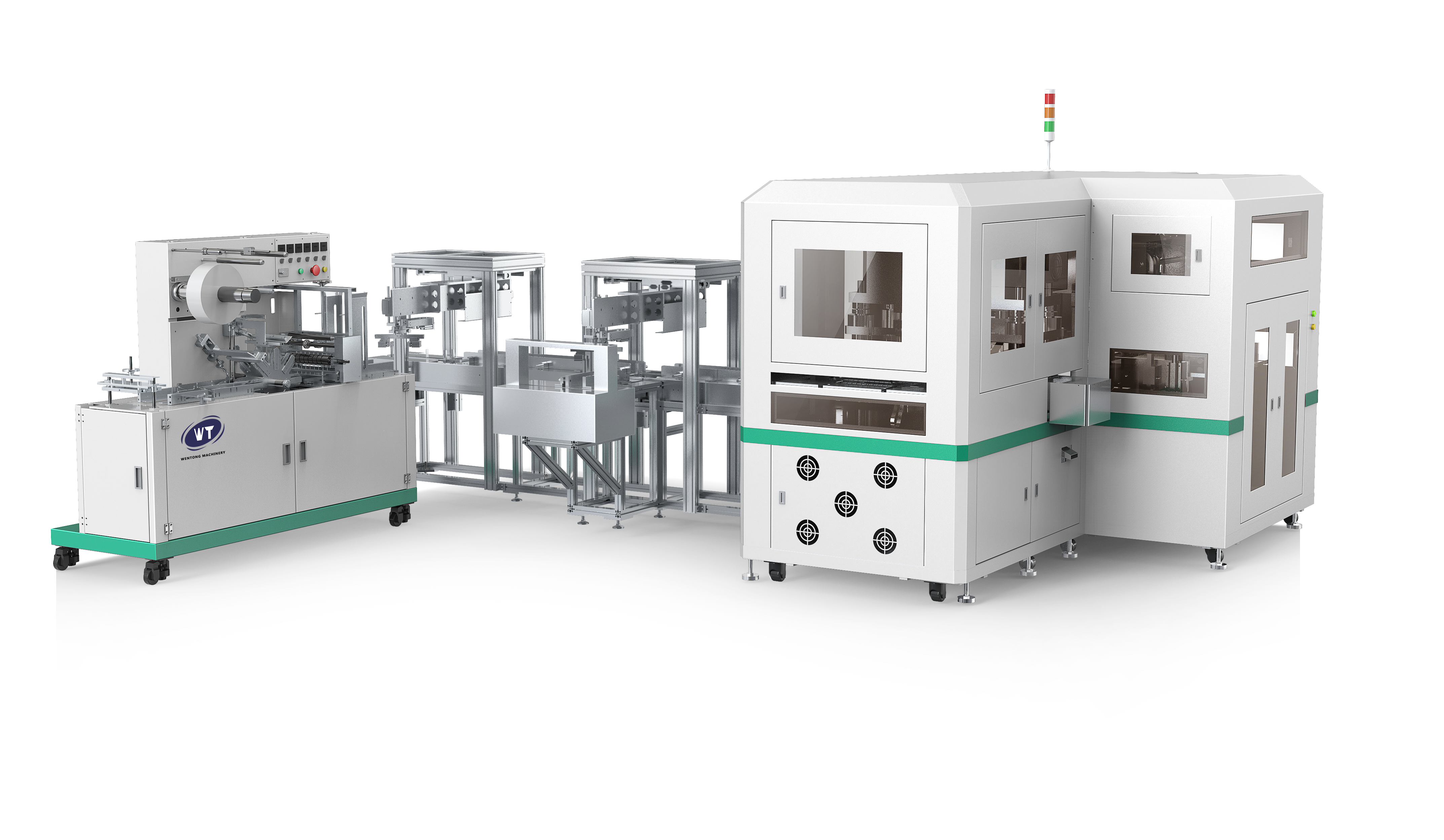

With the increasing demand for smart cards and membership cards in the market, choosing a reliable and efficient card-making machine is essential for enterprises that want to improve their competitive advantage. We are a card-making equipment manufacturer in Shenzhen, China, providing automated and multifunctional card-making production for global customers. This article aims to illustrate the equipment that suits the production needs of customers and explore the versatility, the diversity of building materials, and the automation of the equipment.

The main function of the card-making machine is to make various cards such as smart cards, plastic cards, metal cards, wood cards, and membership cards. The production process of card-making equipment is different for each material. For example:

Mainly composed of PVC and PET plastics, the machine must facilitate the chip embedding, printing, and encoding processes.

The system must have high-precision, wear-resistant stamping dies for processing stainless steel or aluminum.

In terms of cutting and surface treatment capabilities, care must be taken to avoid chips and burrs.

If your business is producing and using a variety of materials, then choose equipment with high versatility. This is to minimize the loss of productivity due to mold changes.

Modern card-making equipment has an automatic system for automatic classification and sorting of multiple outputs of the same type, which maximizes production efficiency. For example:

Automatically sorts and organizes by type, size, or code assigned to the card; best for bulk orders.

The automatic sorting and classification system reduces the chance of manual errors and runs through all aspects of card production and packaging. It has obvious advantages for customers in Europe and the United States, where labor costs are high.

The core advantages of card-making equipment should include production speed, accuracy, and long-term stability:

The card-making equipment can produce more than 2,000 cards per hour and maintain very high precision, so it is very suitable for mass production. There is also card-making equipment suitable for small and medium-sized enterprises, which is equipped with automatic sorting and classification, which greatly reduces labor costs.

Our smart card production equipment uses laser etching, so its cutting precision is very high, reaching the micron level, ensuring the integrity of the chip and printed pattern inside the card.

The system should have automatic self-diagnosis and remote monitoring capabilities. High cost performance, strong durability, and adaptability to the global supply chain are the advantages of Shenzhen manufacturing.

The equipment has

When choosing a card printer, consider the manufacturer's global service coverage. As a Shenzhen-based company, we offer

The remote diagnostic capabilities of the IoT system greatly reduce your maintenance time.

Configure the system to meet specific regional requirements, such as EU CE or North American FCC regulations.

Ensure that suppliers have sufficient resources to prevent production cycles from being interrupted by machine failures.

In addition, AI quality inspection will increase the value of the equipment while maintaining the modular design, allowing future development, such as the process of adding more biodegradable and recycled materials as the industry transitions to green manufacturing.

The selection of card manufacturing equipment is a balance between production needs, automation, and global service. Our equipment retains the innovation of Shenzhen manufacturing in technology and practical experience and serves the efficient production of membership cards, smart cards, and multi-material cards for overseas customers.