With the increasingly fierce competition in the global printing industry, card product (smart card, game card, poker, animation card, bank card, etc.) production enterprises are paying more and more attention to reducing costs and improving work efficiency. The trading card die-cutting machine is the most important equipment in the production process of such products. Its technical level directly affects the production cost and the competitiveness of the product. Shenzhen is an important industrial center for global intelligent manufacturing equipment. A number of poker card die-cutting machine R&D and production enterprises with core technologies have emerged. Its automatic trading card die-cutting machine has a number of core advantages, reducing costs in terms of labor, efficiency, scrap rate, long-term operation and maintenance, etc. Provide efficient production solutions for global printing industry customers. This article will systematically analyze the cost reduction logic of automatic poker card die-cutting machines from the perspectives of core value, cost recovery cycle, total cost of ownership, etc., and provide professional guidance for industry practitioners.

The three major problems of traditional die-cutting cards are high labor costs, low production efficiency, and difficult control of the scrap rate. These problems make it difficult for enterprises to make profits. The automatic trading card die-cutting machine solves these three major problems from the source through the upgrading of core technologies, making the control of production costs possible.

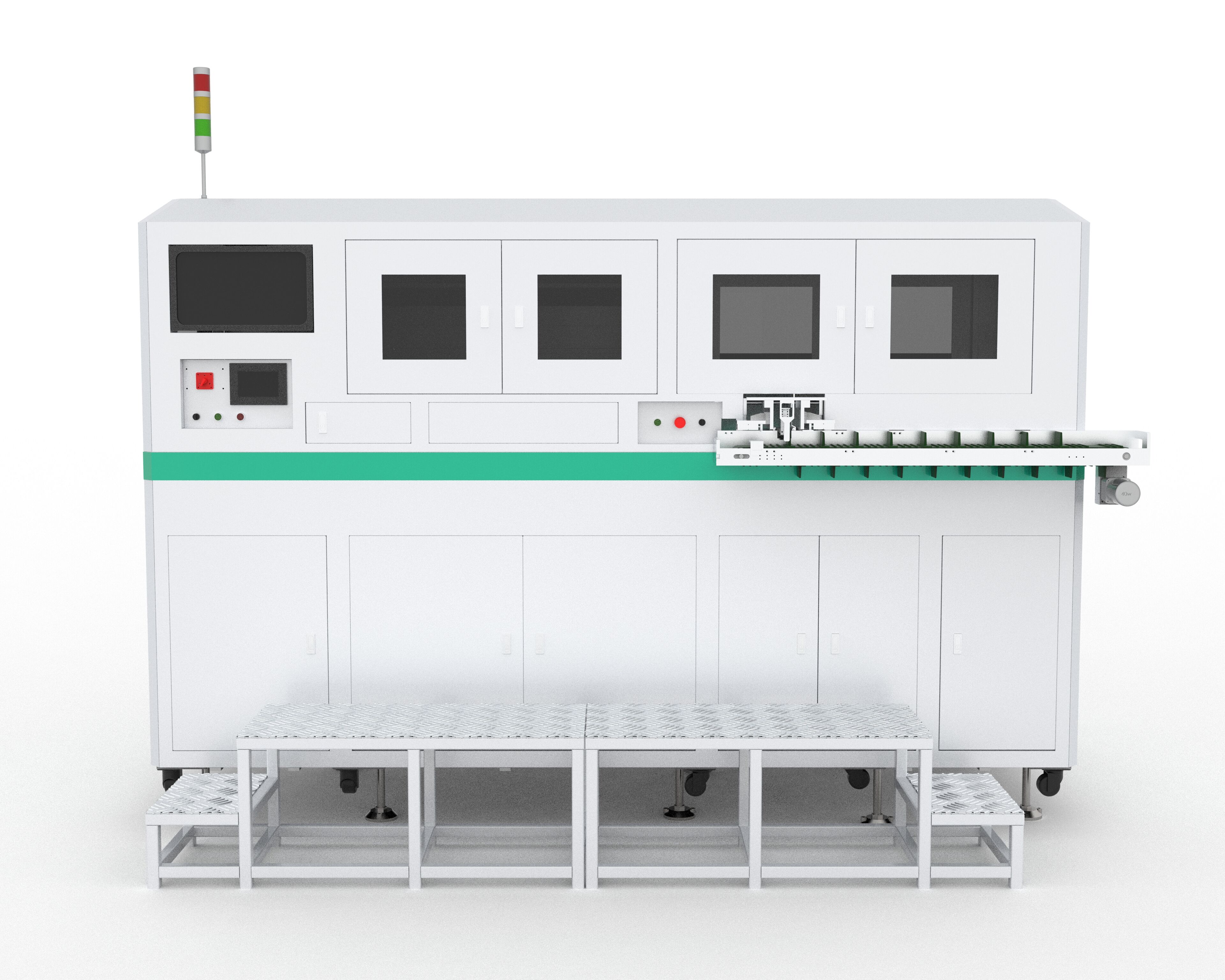

The automatic trading card die-cutting machine has a fully automatic production chain, including precise feeding, automatic card collection, waste removal, automatic sorting and finishing, and other processes, without too much manual operation. The fully automatic machine only needs one person to watch and assist, while the traditional semi-automatic machine needs 3 to 5 people to cooperate to complete the work of feeding, sorting, and waste disposal. The average labor cost in the global printing industry is 6,000 yuan per person per month. This means that each machine can save 144,000 to 240,000 yuan in labor costs each year. In some places, labor costs are much higher than in China, especially for foreign customers. That's why automated equipment is more useful in saving labor costs.

The most important thing for automated equipment to reduce unit costs is to improve production efficiency. The machine is equipped with a 7.5 kW automatic servo system. The servo motor has the characteristics of fast response speed, high running precision, and stable power output, so the punching speed is fast and the precision is high. The automatic trading card die-cutting machine can produce 6,000 to 8,000 cards per hour, which is more than twice the speed of 3,000 cards per hour of traditional equipment. The equipment is also equipped with wooden light molds, and it only takes 2 to 3 minutes to replace the molds, which is much faster than the traditional mold replacement time of more than 30 minutes. For small-batch and multi-variety orders, quick mold change can reduce equipment downtime and make better use of equipment. Based on 8 hours of production per day, automatic equipment produces 24,000 to 40,000 more cards per day than traditional equipment. The increase in output per unit time reduces the fixed cost allocation of unit products.

Another important part of controlling the cost of automated equipment is to reduce the scrap rate. The waste rate of traditional manual die-cutting machines is usually 3% to 5% due to human error, inaccurate feeding, etc. The automatic transaction card die-cutting machine adopts a 7.5 KW servo-driven precision punching mechanism and a precision feeding system. The machine can control the punching process with millimeter-level precision. The stamped products have no burrs and the size consistency is very good. The scrap rate can be controlled at 0.5%. For example, each factory produces 100,000 cards per day, and the cost of each card is 1 yuan. The loss of waste products of traditional equipment is 3,000 yuan to 5,000 yuan per day, while the loss of waste products of automated equipment is only 500 yuan. This means that automated equipment can save 880,000 to 1.64 million yuan in waste losses each year. The automatic waste discharge function of the equipment can also collect and process the waste generated during the stamping process in a timely manner. This avoids the accumulation of waste affecting production and reduces the cost of waste disposal and environmental protection.

For card products, product quality is directly related to the consistency of production, while the speed of delivery will affect the likelihood of customers working with you again. Both of these things indirectly affect the company's competitiveness in the market and the efficiency of spending money. By upgrading the technology, the automatic playing card die-cutting machine has improved production consistency and accelerated order delivery. This translates into long-term cost savings by making customers more satisfied.

The automated equipment uses a complete customized solution to ensure consistent production. The feeding mechanism, punching system, and finished product collection link of the equipment are carefully matched and debugged to ensure that the punching size and edge flatness of each card are very consistent. The punching precision of the automatic transaction card die-cutting machine can reach ±0.01 mm, which fully meets the industry standards. This is especially important for making smart cards, bank cards, and other products that require very high precision. The pass rate of products produced by automated equipment can be maintained at more than 99.5%, reducing the cost of rework and returns caused by quality problems. This is better than the quality fluctuations caused by traditional manual operation of equipment or unstable equipment. According to industry data, the cost of rework due to inconsistent product quality for traditional manufacturing companies accounts for 8% to 12% of total costs. Automated equipment can cut that cost to less than 2% by making production more consistent.

The main benefit of automation for happier customers is faster order delivery. The above-mentioned increase in production efficiency has greatly shortened the order production time. For example, it takes 3 to 4 days for traditional equipment to produce 100,000 game cards, while automated equipment only takes 1 to 2 days. On the other hand, the equipment also has a customized finished product collection method, which can be collected in order or by category according to customer needs. This means that there is no need for a second manual sorting, which further shortens the delivery cycle of orders. The equipment has functions such as punching, book cutting, and filter paper, which can meet the needs of various orders. This helps companies more easily meet different order requirements and improves their ability to accept orders and deliver them on time. By delivering orders quickly and reliably, companies can increase customer satisfaction, reduce the cost of penalties for late deliveries, and increase customer loyalty, which reduces the cost of acquiring new customers. According to market research, if customer satisfaction increases by 10%, companies can expect repeat customers to increase by 15% to 20%. This is because the cost of acquiring a new customer is 5 to 8 times higher than the cost of retaining an existing one.

Printing companies need to invest a certain amount of equipment funds in the early stage when purchasing automatic poker card die-cutting machines. That is why the payback period of the equipment is an important factor in business decisions. By using specific data, such as how much labor is saved, how much waste is reduced, and how much efficiency is improved, it can be calculated how long it will take for automated equipment to recover costs.

First, clarify the basic parameters (based on the global printing industry average and the real data of an automated transaction card die-cutting machine of a company in Shenzhen): 1. The equipment purchase cost is as follows: Each fully automatic transaction card die-cutting machine costs about 600,000 yuan, and each traditional semi-automatic machine costs about 200,000 yuan, which is 400,000 yuan more. Labor cost savings: RMB 144,000-240,000 in labor costs are saved each year (calculated based on savings of 3-5 people); 3.4. Costs saved due to the decline in the scrap rate: RMB 880,000-1,640,000 is saved each year; Additional income brought by the increase in efficiency: Calculated based on an average of 30,000 more cards produced each day and a profit of RMB 0.1 per card, about RMB 1,080,000 in additional income is created each year (30,000 cards/day × 360 days × RMB 0.1/card); The cost of rework, the cost of fines, etc. add up to about RMB 100,000 each year.

According to the comprehensive calculation, the automatic transaction card die-cutting machine can save the total cost and additional benefits of about 2.604 million yuan to 3.46 million yuan per year. After deducting the 400,000 yuan of costs invested in the early stage, the cost recovery period is only 0.12-0.15 years, that is, 1.4-1.8 months. This does not include the depreciation of the equipment. Even if the depreciation of equipment (60,000 yuan per year for 10 years) is taken into account, the cost recovery period is only 1.5-2 months. The time for cost recovery will vary depending on the production scale, labor costs, and order structure of different enterprises. But overall, the cost recovery speed of the automatic trading card die-cutting machine is far higher than the industry average, and it has a very good return on investment.

When businesses consider the cost-effectiveness of an automatic trading card die cutter, they need to consider the total cost of ownership (TCO). This includes all costs over the machine's lifetime, such as energy use, maintenance, upgrades, and other costs, as well as the initial purchase price and direct savings in production costs. The automatic poker card die-cutting machine manufactured by Shenzhen enterprises has many advantages in controlling the total cost of ownership. This makes the machine more cost-effective in the long run.

The 7.5 kW automatic servo system in the automatic poker card die-cutting machine is energy-saving, which means it consumes less energy when running. The servo motor automatically reduces energy use when there is no load or a light load. Compared with ordinary motors on traditional equipment, it can save 30% to 40% of electricity. If the equipment is used for 8 hours a day, and the average industrial electricity price is 0.8 yuan/kWh, the daily electricity cost of traditional equipment is about 48 yuan (7.5 kW × 8 h × 0.8 yuan/kWh). The energy cost of automatic equipment is only 28.8-33.6 yuan per day, which means that 52,560-69,360 yuan of energy cost can be saved in a year. In some areas outside the United States where electricity costs are high, the energy savings are even more pronounced.

The main feature of the automatic trading card die-cutting machine that makes it easy to maintain is that it is very durable. The most important parts of the equipment are made of high-quality alloy materials and are carefully processed. The service life is far higher than the industry average, which means that the frequency of parts replacement is lower and the cost is lower. At the same time, the equipment has an intelligent fault early warning system, which can monitor the operation of the equipment in real time, give early warning before the occurrence of the fault, and eliminate the downtime loss and high maintenance cost caused by the sudden fault. At the same time, the equipment is equipped with wooden light molds, which are easy to maintain, low in cost, and quick to replace. Compared with the old-fashioned metal molds, the mold maintenance cost can be saved by 30,000 to 50,000 yuan per year. The total maintenance cost of automatic equipment is about 20,000 to 30,000 yuan a year. This is less than the maintenance cost of traditional equipment, which is 50,000 to 80,000 yuan per year. This means that 30,000 to 60,000 yuan can be saved in a year.

The automatic poker die-cutting machine produced by Shenzhen enterprises adopts a modular design and can be easily upgraded. As the industry technology advances and customer needs change, companies can upgrade their equipment without having to buy new equipment. They can do this by replacing certain modules, such as the servo system or the hot stamping process module. This greatly reduces the cost of equipment upgrades. If the customer wants to add the hot stamping process in the later period, he only needs to spend 50,000 to 80,000 yuan to replace the hot stamping module. This allows for simultaneous hot stamping and die cutting. To achieve this, replacing all the traditional equipment would cost more than 200,000 yuan. The company also offers excellent technical upgrade services to customers outside the United States to ensure that equipment can keep up with changes in market demand, have a longer service life, and become a better long-term investment.

The automatic poker card die-cutting machine directly realizes precise cost control in the production process by reducing labor costs, accelerating production speed, and reducing scrap rate. At the same time, the machine indirectly reduces the cost of customer development and maintenance by improving production consistency, accelerating order delivery speed, and improving customer satisfaction. The ultra-short cost recovery cycle (1.4-1.8 months) of this model allows enterprises to quickly recover their investment. In terms of total cost of ownership control, the model further enhances long-term cost benefits through energy-saving operation, lower maintenance costs, and flexible upgrade paths.

The average labor cost of customers has decreased by 70%, production efficiency has increased by 120%, the defect rate has decreased by 85%, the order delivery cycle has been shortened by 60%, customer satisfaction has increased to more than 95%, the average cost recovery cycle of equipment is only 1.6 months, and the total cost of ownership throughout the life cycle has decreased by 45% compared with traditional equipment.

For card product manufacturers in the global printing industry, the introduction of automatic card die-cutting machines with core advantages such as unique texture, durability, and wide application can not only reduce production costs but also improve product quality and market competitiveness. Shenzhen enterprises have many years of technical experience and can serve global customers. They provide customized one-stop solutions for overseas customers, helping them operate their businesses more efficiently at a lower cost. They are also a good choice for global printing companies looking to upgrade their production equipment.