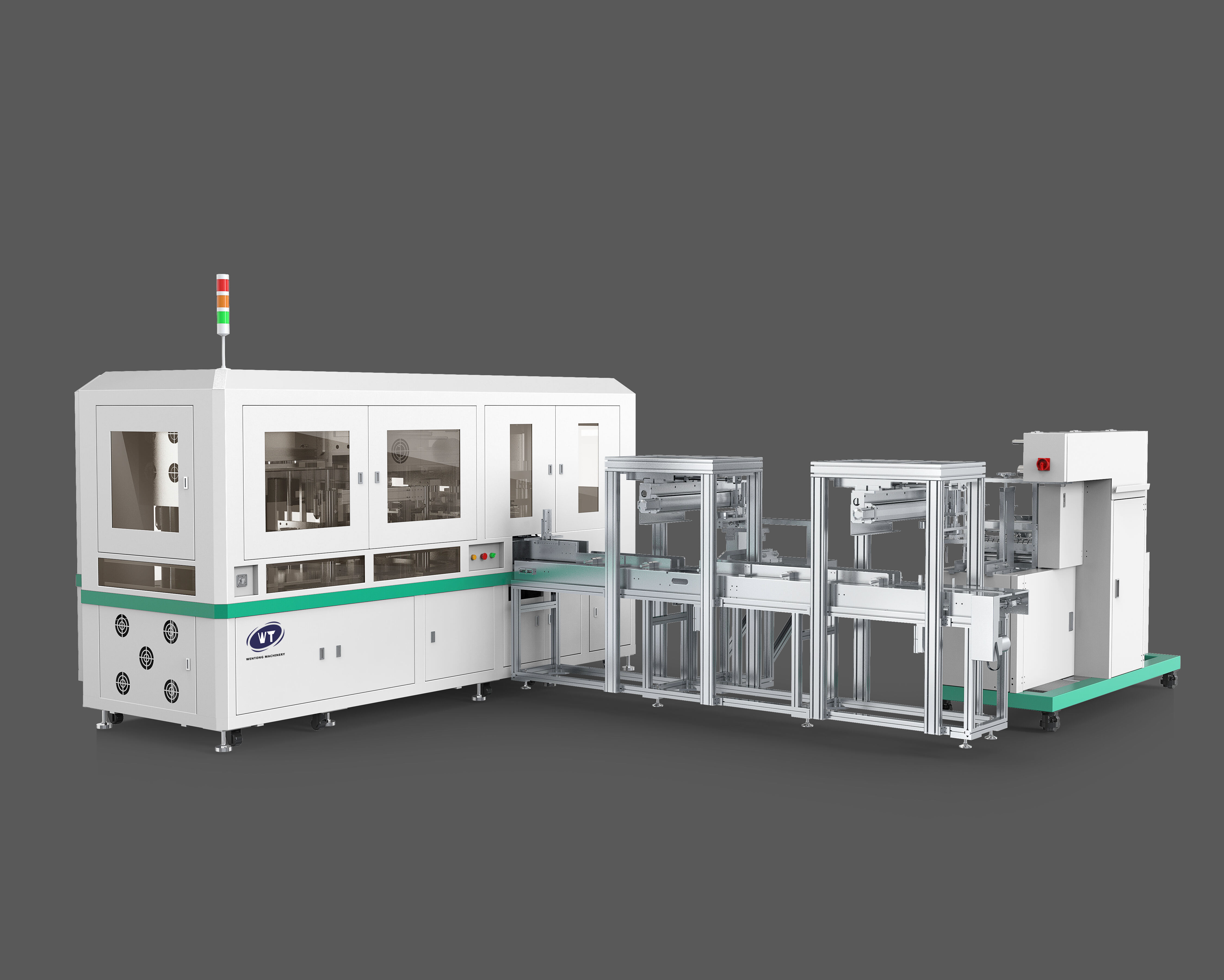

The global printing industry is developing rapidly, and the application of card products is also growing. The market's demand for precision, efficiency, and personalization in card production is constantly growing. Including the playing cards and bank cards we use every day, to the anime collection cards and metal texture game cards with collection value. The trading card die-cutting machine is the most important equipment in the card production process. It is used to make a wide variety of products, including cards, smart cards, game cards, playing cards, animation cards, and bank cards. Because it can accurately feed cards, automatically collect cards, and automatically discharge waste. Shenzhen is a major hub for the global intelligent manufacturing industry, and our company has been deeply involved in the research and development and production of transaction card die-cutting machines for many years. With an advanced technology system, we provide high-quality equipment with unique texture, durable quality, and wide application, as well as customized overall solutions for the global overseas market. This article will introduce the customized application solutions of the trading card die-cutting machine in detail for the production needs of different types of cards and provide professional technical advice for people in the printing industry.

As a classic form of mass entertainment, poker cards are produced in large batches, at high speed and with high precision. The speed and stability of the die-cutting process are particularly difficult to keep up with. In the process of making playing cards, the die-cutting speed directly affects the production efficiency, while the wear resistance of the tool affects the product qualification rate and the ability to continuously make cards. The customized settings of the trading card die-cutting machine are mainly based on these two major needs.

The poker die-cutting machine customized by our company adopts a 7.5 kW automatic servo system to meet the needs of rapid production of poker. The system has a fast response speed and stable operation. It can cut 300 to 500 sheets per minute, which is more than 40% faster than traditional equipment. This is very suitable for the rhythm requirements of large-scale poker production. At the same time, the precise control of the servo system can ensure the accuracy of feeding even at high speed. The feeding error is controlled within ±0.1 mm, which avoids the problem of die-cutting misalignment caused by inaccurate feeding.

We chose tungsten steel wear-resistant tools according to the characteristics of poker paper (usually 250-300 g/m² poker special paper). The hardness of the tool can reach above HRC60, and the service life is three times that of ordinary tools. It remains sharp after punching 1 million playing cards, which means fewer tools need to be replaced, there is less production downtime, and consumable costs are lower. The tool also features a custom corner radius design to meet the standard requirements for corner radius die-cutting of playing cards. The radius of the rounded corner can be changed according to the needs of different regions (such as international standard rounded corners or regional customized rounded corners) to ensure that the edges of the die-cut playing cards are smooth and burr-free and meet the industry quality standards.

A large amount of waste paper edges will be generated during the production of playing cards, so this needs to be paid attention to. The customized trading card die-cutting machine has an automatic waste removal system, which uses a negative pressure adsorption device to collect the waste paper edges in real time and move them to the waste box. It keeps the production environment and equipment running smoothly and cleanly and improves the smoothness of production.

As a major component of the fan economy, the production of animation collection cards not only requires very precise die-cutting effects but also has to deal with the problems brought about by special coated materials. In order to make the collection value higher, the animation collection cards often go through surface treatment processes such as film coating, hot stamping, and UV. These special coating materials, such as PET film coating and UV curing coating, have high hardness and strong toughness. Traditional die-cutting tools are prone to problems such as coating tearing and edge warping. Therefore, when customizing trading card die-cutting machines, their adaptability to different coatings and the accuracy of die-cutting need to be considered.

Due to the difficulty in die-cutting special coated materials, we first made an easy-to-adjust modification to the die-cutting pressure of the trading card die-cutting machine. The machine has an intelligent pressure sensing system that automatically changes the die-cutting pressure according to the thickness (0.1-0.5 mm) and hardness of the coated material. The pressure can be varied from 0 to 500 N to ensure that the coating is not damaged when the material is cut. For example, when die-cutting UV-cured coatings, the machine will automatically reduce the initial pressure and adopt the "progressive die-cutting" method to pre-crack the coating first and then perform the overall die-cutting. This can prevent the coating from tearing.

The customized trading card die-cutting machine adopts a double servo feeding mechanism, which is driven synchronously before and after to ensure the smooth movement of materials. It is also equipped with a high-definition visual positioning system, which can find the printed patterns on the card in real time. The die-cutting error can be controlled within ±0.05 mm, ensuring that the card pattern is complete and undamaged after die-cutting and the edges are neat. This is exactly what the animation collection card needs in detail. At the same time, the equipment can quickly switch between wooden molds and light molds and has strong applicability to the common special-shaped die-cutting needs of animation collection cards, such as character outlines and brand LOGO customized shapes. The mold change only takes 2-3 minutes, and the replacement efficiency is 80% higher than that of the traditional steel mold. This greatly reduces the cost of changing lines for small-batch, multi-variety production.

The equipment has a soft finished product collection device to protect the finished product. The conveying roller and the receiving tray are made of silicone material, and the coating on the surface of the card will not be scratched after die-cutting. It also has an automatic dust removal function, using an ion air gun to remove static electricity and dust from the surface of the card. This keeps the finished product clean and gives the collectible card a better feel and appearance.

Metal texture cards, such as metal foil composite cards and stainless steel brushed cards, are favored for high-end membership cards, commemorative cards, and high-end game cards because of their excellent appearance and feel. This kind of card is usually made of metal foil and paper or plastic. This material has high hardness, good toughness, and good thermal conductivity. During the die-cutting process, problems such as incomplete die-cutting, edge burrs, and material deformation often occur. Therefore, it is important to be able to change the settings and make the trading card die-cutting machine work the way you want it to.

The most important thing to know when making metal cards is how to change the speed of the die-cutting machine. Metal composites are very resistant to cutting, so if the die-cutting speed is too high, the tool will have to work very hard, which will wear the blade faster and tear the material. The custom trading card die cutter allows you to die cut at variable speeds. For metal texture cards, the speed should be set to 150 to 250 sheets per minute. When the tool slows down, it can fully contact the material, making the die-cutting more complete. At the same time, the servo system of the equipment can keep the speed stable, avoiding the decline of die-cutting accuracy caused by the change of speed.

The key to deburring the edges of metal texture cards lies in the precise control of the die-cutting gap. The gap between the upper and lower dies needs to be determined according to the total thickness of the metal composite material, usually between 0.3 and 0.8 mm. If the gap is too large, the die cutting will not be thorough. If the gap is too small, the material will be squeezed and deformed, and the edges will be rough. The custom trading card die cutter has a micron-level gap adjustment device that allows you to precisely set the gap value through the digital display. The adjustment accuracy is 0.01 mm, so the gap is always perfectly matched to the thickness of the material. For example, if your metal foil composite card is 0.5 mm thick, you should set the die-cutting gap to 0.03–0.05 mm. This will ensure that the die-cut edges are smooth and free of burrs.

In addition, due to the good thermal conductivity of metal materials, the equipment is also equipped with a tool cooling system, which cools the tool in real time through circulating cooling water. This can prevent the tool from softening due to frictional heat generation during the die-cutting process, making the tool more wear-resistant and the die-cutting more stable. This production method also reflects the versatility of the equipment. For example, metal texture cards can be punched and then hot stamped. The integrated process design reduces the process conversion time and improves the production efficiency.

Customer needs in the printing industry are very specific. Different types of cards, production scales, and quality standards have different die-cutting solutions. Based on our experience in providing services in the global overseas market, we have created a complete customized die-cutting solution service process. The process includes all aspects from researching customer needs to implementing solutions and then to operating and maintaining solutions. Throughout the process, we provide professional support to customers to ensure the accuracy and practicality of the solution.

Step 1: Conduct sufficient demand research. The professional technical team fully understands the core needs of customers through online communication, on-site visits, and other methods. Including the type of cards (such as playing cards, anime cards, metal texture cards, etc.), the characteristics of the substrate (material, thickness, coating), the production scale (daily output, batch quantity), the quality requirements (die-cutting accuracy, edge smoothness), the subsequent process (whether it needs to be equipped with hot stamping, card sorting, etc.), the site conditions, the budget range, etc. At the same time, we collect the data of the customer's existing production process to understand the problems existing in the existing die-cutting process. This gave us a starting point for designing our solution.

Step 2: Create a solution that fits your needs. Based on the survey results, the technical team will customize the solution design. The design mainly includes three aspects: selecting appropriate equipment configuration, setting die-cutting parameters, and integrating auxiliary functions. In terms of equipment configuration, the servo power and die-cutting speed are selected according to the production scale, the tool type and mold material are selected according to the material characteristics, and functions such as hot stamping and automatic sorting are added according to the needs of subsequent processes. In terms of pre-setting of die-cutting parameters, the core parameters such as die-cutting speed, pressure, and gap will be set in advance according to the process points of different card types. This can save customers time in debugging the machine later. For example, auxiliary functions such as the finished product collection method (by category or in order) and the waste disposal method are customized according to the needs of each customer.

Step 3: Test and improve the prototype. After the plan is determined, a prototype is made, and the customer selects the material he wants to use for the die-cutting test. The test includes the precision of die cutting, efficiency, the qualified rate of finished products, the stability of equipment operation, etc. We will feed back the test results to the customer and modify the plan according to the customer's opinions until all the customer's needs are met. For example, when a customer tested an animation collection card, they found that the UV coating had a slight warping problem. The technical team solved the problem by adjusting the die-cutting pressure and adopting a progressive die-cutting process.

Step 4: Build the device, put it together, and work out any bugs. Once the design is approved, the next step is to build the equipment. The production, assembly, and quality inspection of parts are strictly carried out in accordance with the customized plan. After the equipment is manufactured, professional technicians will be sent to the customer's site for installation and commissioning to ensure the normal operation of the equipment. The customer's operators will also receive professional training, including how to use the equipment, how to change settings, how to perform daily maintenance, etc.

Step 5: After that, there is operation and maintenance and technical support. During the warranty period, customers should receive comprehensive after-sales service, including free repairs, regular inspections, and replacement of parts. There should also be a 24-hour technical support hotline that customers can call for help with technical issues and faults. At the same time, according to the changes in the industry and the changes in the production needs of customers, we provide customers with equipment upgrades and program optimization suggestions to keep their production process stable and efficient.

Our customized trading card die-cutting machine has eight core advantages that work together to meet the production needs of different card types. First, the unique texture presentation, through precise die-cutting control and finished product protection design, to ensure that the card edge is smooth, the surface is clean, and the visual and tactile texture of the product is improved; Second, the excellent durability and the use of high-quality tools, servo systems, and other core components mean the average service life of the equipment can reach 8-10 years, 30% higher than the industry average. Third, the powerful multi-application, one-machine, multi-purpose can achieve a variety of materials, such as cards, books, filter paper, and other materials punching, to meet the diverse production needs of customers; Fourth, the integration of the hot stamping process can be directly matched with the hot stamping module to achieve integrated die-cutting and hot stamping production and improve production efficiency. Fifth, the mature technical system, relying on years of research and development experience, the equipment runs with high stability, and the failure rate is less than 1%; Sixth, the integrated customized overall solution, from equipment to service, the whole process is customized, and the customer needs are accurately matched; Seventh, the automatic classification and sorting function can realize the collection of finished products in order or by classification, reducing the subsequent manual sorting cost. Eighth, the punching is accurate and there is no burr, and the error of die-cutting is within ±0.05 mm.

These key advantages make trading card die cutters very useful in printing businesses. Not only can it make production more efficient and less costly, but it can also make products better and more value-added, thus helping customers compete better in the market. Customized die-cutting solutions can help customers respond quickly to market changes and meet the production needs of different types of cards. This is especially important as the global card market continues to grow.

The customized setting and process optimization of the trading card die-cutting machine are the guarantee for the high-quality and fast production of cards. Through the customized adjustment of the core components of the equipment, such as die-cutting speed, pressure, cutter, parameters, etc., it can meet the needs of different types of products, such as playing cards, animation collection cards, and metal texture cards, provide all-round customized services, and accurately solve the production problems of different customers.

Industry data shows that the global card market will be worth $85 billion by 2025. Customized cards will account for more than 40% of the total. This trend has brought huge market growth space for trading card die-cutting machines. Our company is a smart manufacturing enterprise in Shenzhen. With the help of the technologically leading customized trading card die-cutting machine, we have helped more than 300 printing enterprises in more than 50 countries and regions around the world to achieve transformation and upgrading. Customers said that the equipment has increased production efficiency by an average of more than 35%, reduced the cost of consumables by more than 25%, and kept the pass rate of finished products above 99.8%.

With the continuous improvement of printing technology and the continuous rise of market demand, the trading card die-cutting machine will be more accurate, more practical, and more intelligent. We will continue to work hard on technology research and development, improve our customized solutions, and provide better equipment and services for customers in the global printing industry. We will also help our customers achieve quality growth.