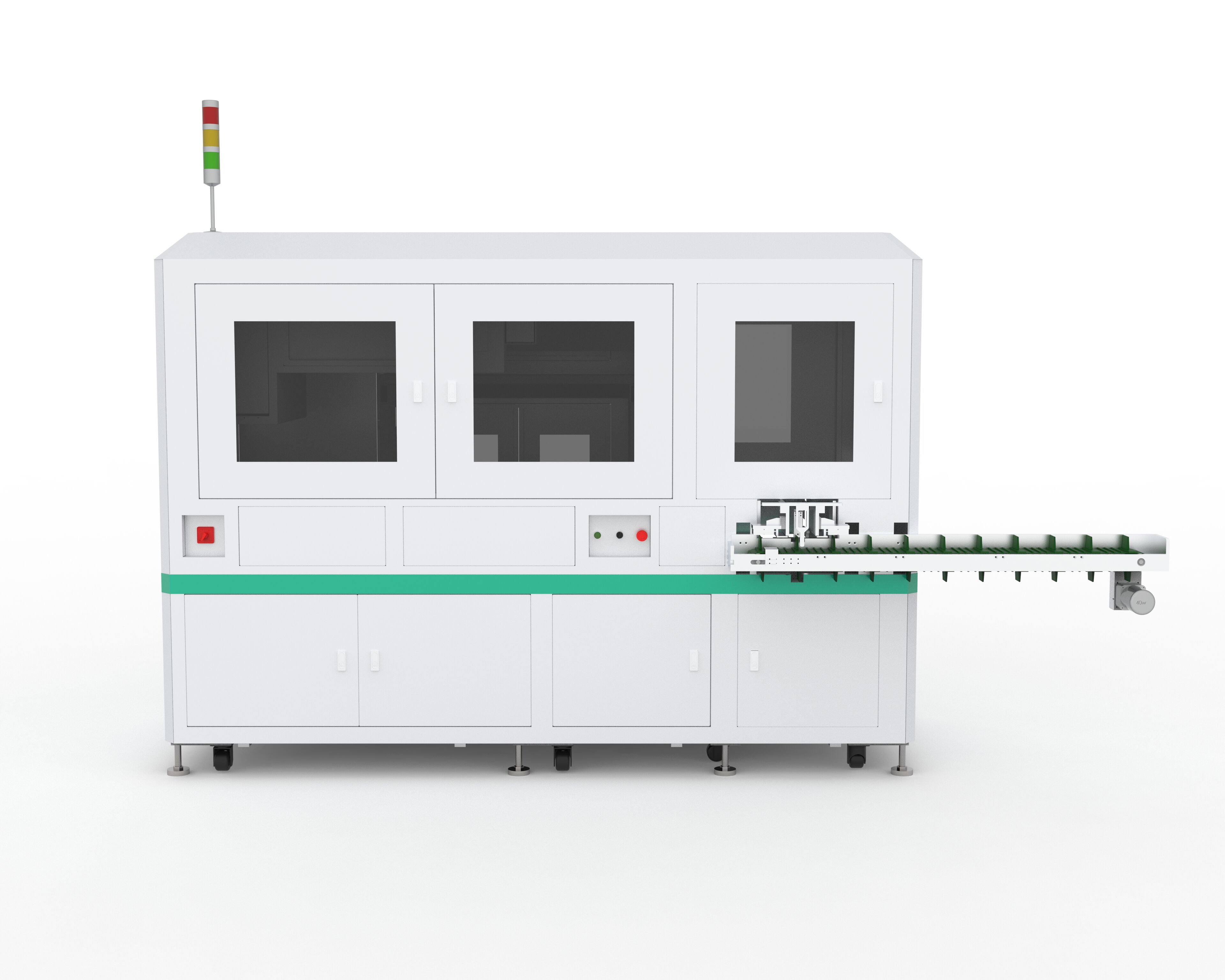

The application of card punching machines is far more than making game cards, membership cards, and smart cards. We are a company in Shenzhen, China, and have been committed to the research and development and production of card punching machines. We have mature technology, and the multi-functional card punching machine is sold to overseas markets. In addition to punching and cutting filter materials such as oil filters, steamers, coatings, and various filter papers, it can also punch and cut various materials such as paper, fiber, wood, and plastic, plus paper cards, calendars, children's books, brochures, document bags, envelopes, and fiber materials. The card punching machine serves the diversified production of global customers, including card game developers, printing plants, filter paper industry, etc.

The first card punching machine that expanded the industry's vision from the limitation of "only making cards" to multi-scene production. This enables our machines to be production partners for customers worldwide.

The equipment used in the card production center can effectively produce game cards, membership cards, and smart cards and is also suitable for cultural and creative products such as postcards and greeting cards, seamlessly connecting the personalized needs of card game developers, publishers, and cultural and creative product designers. The production materials can be paper, fiber, wooden cards, and various grades of plastic. The punching machine adopts a 7.5 kW servo drive mechanism, and the production process is accurate and controllable. High-speed and reliable batch production, and completed with extremely high precision.

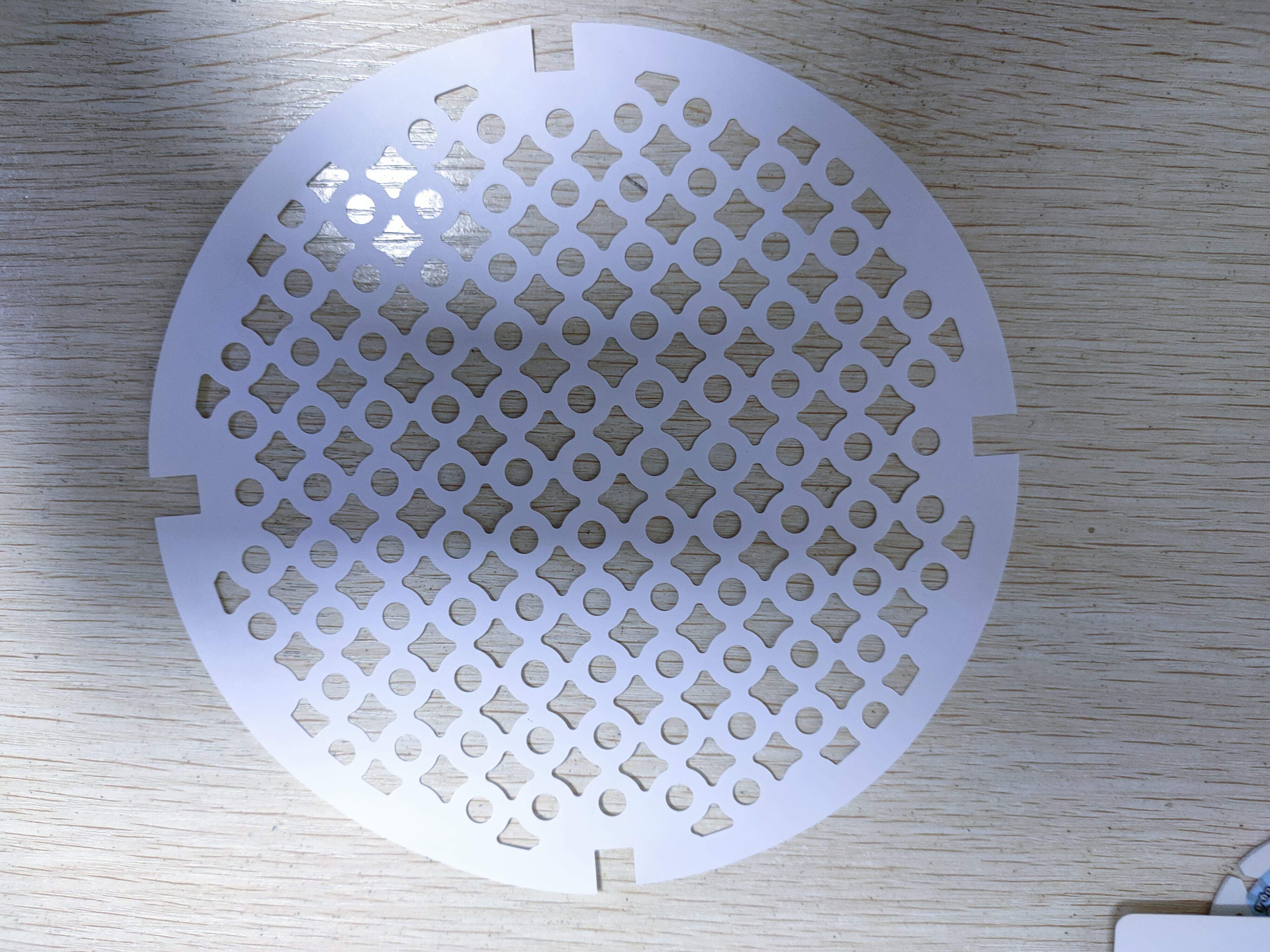

The punching of filter paper, especially in oil filter paper, steam paper, and coated paper, is the core competitive advantage. This equipment is built to fully serve the mass production needs of filter paper manufacturers. In addition, it can be used as a die-cutting and finishing tool for a variety of products, including jigsaw cards, children's books, literacy cards, document bags, and envelopes. It is a one-stop solution for printing house production.

In response to the core needs of children's cards and jigsaw cards, which are "safe and burr-free, accurately spliced, and durable," our card punching machine provides a unique process design.

The 7.5 kW automatic servo system ensures that the punching error is at the micron level, ensures the seamless splicing of puzzle cards, and ensures that the edges of children's cards are smooth and burr-free, and there are no safety hazards.

For children's products made of paper, wood, food-grade plastic, etc., we have designed special punching dies to efficiently preserve the texture of the materials. It also improves the competitiveness of the product.

By combining hot stamping technology with our card punching machine, you can hot stamp exquisite patterns and cartoon images on children's cards and puzzle cards to increase the value and attractiveness of the products. The durability of the equipment also enables it to run continuously for 24 hours to meet the delivery time of manufacturers' batch orders.

In order to make the punching machine adapt to the production of oil filter paper, steamer paper, coated paper, filter paper, and other products, we designed it to respond to the production pain points of filter paper products such as "large batch, miscellaneous specifications, and high precision requirements."

Filter paper punching and cutting of various sizes and thicknesses can be customized. We can customize filter paper punching and cutting of various sizes and thicknesses for customers. The exclusive customer mold can be made at the fastest speed. Single-sheet and batch continuous punching and cutting production can be switched seamlessly to meet the needs of multi-size orders.

The finished products after punching and cutting can be automatically classified and sorted according to the receiving or cutting orders. The automatic sorting system reduces manual intervention, saves labor, and improves production efficiency. This increase in automation has minimized manual intervention, saved manpower, and improved production efficiency.

Our punching system is designed to maintain the integrity of the filter paper and ensure that the edges of each filter paper are clean and tidy, thus eliminating any damage. Our collection system, designed for non-custom finished products, prevents any secondary contamination and adheres to the strict quality standards required by filter paper manufacturers.

Customers worldwide can enhance their production processes with eight key highlights. This allows our card punch to help customers in various industries alleviate the problem of low operational efficiency.

The original texture of the material is preserved through customized molds and advanced process strategies, which enhances the market value of cards and filter paper.

The machine frame is made of high-strength materials. To further reduce the maintenance of overseas customers, the core components have been fully aged to adapt to long-term high-intensity production operations.

It can process multiple products, such as card type, filter paper type, paper-plastic combination type, etc., at the same time. One machine can meet the production needs of different scenarios, which undoubtedly saves the investment of multiple devices.

Support the personalized hot stamping process to create products with better surface texture and meet the diversified needs of high-end cultural and creative products, high-end membership cards, etc.

We provide all-round customized services such as mold design, process debugging, and production optimization to meet the customized needs of various industries.

7.5 kW servo system, high-speed and accurate production, automatic sorting and classification, improved production efficiency and labor cost efficiency.

The finished products are collected by order and by category, which facilitates the different post-processing needs of the products.

The high-precision matching servo control of mechanical parts ensures that the edges of all products are smooth and do not require secondary processing.

We are a Shenzhen-based company in China that focuses on the R&D and production of card punching machines, working with customers around the world, including card game developers, postcard manufacturers, and filter paper producers. With years of experience, diverse technologies, and the ability to customize to specific customer needs, we respond to the needs of the international market with reliable production solutions. For those looking for a flexible card punching machine that can adapt to various production environments, please contact us, and we will tailor a solution for you to expand your production capacity.