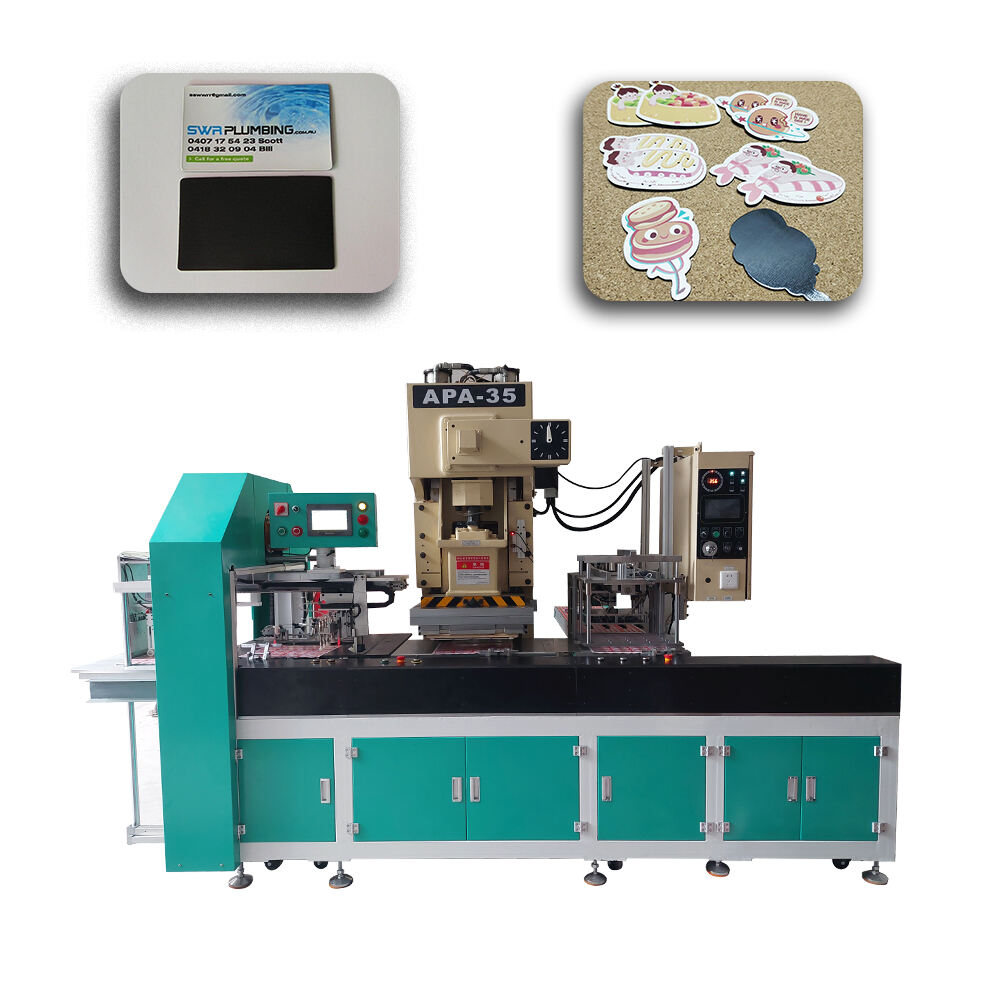

In the global production pattern of soft magnetic card products, the punching machine is the core equipment, which directly affects the product quality, production efficiency, and market competitiveness. Whether it is the pursuit of exquisite texture by card game designers or the need for rapid sorting by filter paper manufacturers, magnetic card punching machines with strong adaptability and far beyond the basic function of "just punching" have become a necessity. This article combines the technical expertise of Shenzhen enterprises in the global market to introduce the core functions and differentiated value of magnetic card punching machines to overseas customers, helping customers to select models, save costs, and improve efficiency.

For soft magnetic card products, the precision of the edge and the quality of the surface are the first steps of competitiveness. High-quality blanking of soft magnetic materials, magnetic tiles, PVC, filter paper, self-adhesive materials, etc., is achieved by using exquisite technology, with a smooth cut, no burr, and dimensional tolerance ≤0.01 mm. Not only does it save the expensive grinding and rework processes, but it also retains the special texture of the product. The exquisite card game cards, high-end greeting cards, and customized cultural peripherals all highlight the extraordinary quality of these products.

Shenzhen enterprises effectively use 7.5 kW servo automation technology, combined with years of overseas market service experience, to design a magnetic card punching machine. The punching action is accurate, fast, and servo-controlled, ensuring production consistency and equipment durability. The punching machine has been measured by customers around the world, and it has been confirmed that the design can run continuously for 8 hours. The machine is expected to be maintained twice a year. This greatly reduces the after-sales cost of overseas customers and minimizes downtime losses.

The high labor costs in overseas markets and the manual feeding and receiving of traditional card-punching machines are still the key bottlenecks in production. In order to solve this problem, card-making machines equipped with automatic feeding and receiving devices have become the basic needs of global manufacturers.

This function adopts an intelligent conveying device to realize automatic loading and positioning of input materials and orderly stacking of output materials. The entire process requires no manual intervention. For large-volume card game manufacturers and card printing integrated factories, it can reduce more than 50% of manual input, reduce the positioning and material waste common in manual methods, and process multiple batches of postcards at the same time. A customized finished product collection can be adopted to collect according to the production sequence for continuous processing. You can also set parameters for preliminary classification and collection. This can maximize efficiency.

Most notably, the automatic feeding system works in synergy with the machine life. Automatic feeding reduces manual operation, thus reducing mechanical wear. Coupled with the advantages of Shenzhen enterprises in materials and precision engineering, these card punching machines can be used for more than 8-10 years. This is in line with the long-term production expectations of overseas customers.

The complexity of the global market requires that soft magnetic cards can meet various needs. Including cards of various sizes, postcards of different materials, greeting cards of different styles, and even filter paper punching of multiple specifications. Manual sorting is inefficient and cannot meet the accuracy requirements of mass production.

The intelligent visual sorting and classification function of the magnetic card punching machine realizes automatic sorting of finished products by real-time detection and computer vision specification recognition, combined with AI empowerment. Whether it is the card game publisher sorting different character cards or the cultural and creative product designer sorting customized small-batch products, this function can achieve a sorting accuracy rate of ≥99.9% and a sorting speed of 300 cards per minute.

The core strength of this feature is its adaptability and ability to serve a wide range of applications. With the soft magnetic card punch, the filter paper company can distinguish the filter paper products with different pore sizes. Greeting cards of various themes can be punched, cut, and sorted. This reduces the production steps and lowers the cost of production equipment.

In the global market competition, "small batch, multiple batches" is the mainstream production mode. Card game developers frequently switch between different card sizes, printing plants manage the production of postcards and promotional cards, and cultural and creative product designers face more customized orders. This requires the magnetic card punching machine to be able to quickly respond to parameter adjustments.

The one-key parameter setting function of the magnetic card punching machine, together with the built-in multiple modules, is more practical. Users can set and save the punching size, pressure, speed, sorting parameters, and even rules of various different products. When switching production tasks, parameters can be set with one click. No technicians are needed, and the machine can be debugged within 30 seconds. This is a great help for small and medium-sized enterprises to handle multi-category orders, especially in terms of production preparation time and order delivery efficiency.

Customers use their own parameter templates and production scenarios through the integrated customized overall solutions provided by Shenzhen enterprises. For example, they can combine the magnetic card punching machine with their own hot stamping equipment for integrated production, which has a better effect. The special-shaped inner core or card for greeting cards can be completed at one time. The product adopts hot stamping technology and a special-shaped inner core to enhance its value.

In addition to the above core functions, the magnetic card punching machine for overseas markets also has eight differentiated advantages to meet the production needs of different target customers:

accurate punching, proper surface treatment, smooth product edges without scratches, meeting the texture requirements of high-end cards and cultural and creative products.

The high-quality alloy body is matched with precision parts to promote long-term high-intensity production overseas and reduce maintenance costs.

can punch and cut magnetic cards, playing cards, filter paper, self-adhesive paper, etc. It can also cut and punch cards at one time to meet the needs of different industries.

It can be connected with a hot stamping machine to improve product value.

With more than 10 years of technical experience, the core components are imported, and the design can adapt to the global voltage and production environment.

We customize equipment, optimize parameters, design linkage, and provide overall solutions according to the production process and product characteristics of customers.

intelligent vision systems improve sorting efficiency and accuracy.

Supports two types of collection methods, by order and by category, to meet different production and circulation needs.

The functions and advantages of the magnetic card punching machine have achieved accurate coverage of target customers in multiple industries around the world:

Card game developers, publishers, and manufacturers: Precise punching and cutting without burrs improves the texture of the cards, automatic feeding and sorting improves the efficiency of mass production, and the hot stamping process is designed for high-end cards to meet the picky standards of global customers for high-quality cards.

Postcard manufacturers and greeting card companies: The material has strong adaptability and can produce composite materials. The intelligent system can sort and switch parameters according to different sizes and themes, reduce labor costs, and meet the needs of multiple orders.

Cultural and creative product designer: Unique products, integrated innovative technologies, and customized solutions to meet the needs of small batches and personalization.

Printing plant: efficient automated production to meet the needs of a variety of printed products The durability and stability of the product ensure the needs of long-term, large-scale production.

Filter paper manufacturer: Multi-functional models, through precise punching, cutting, and sorting, adapt to specific production needs and improve the overall production efficiency of different sizes and different pore sizes of filter paper.

Our company is located in Shenzhen, China, and is a senior equipment manufacturer, with "technology innovation, customer first" as the brand concept. Our equipment has been exported to more than 20 countries and regions in Europe, America, Southeast Asia, the Middle East, etc. We provide not only equipment but also complete and customized solutions. Including equipment selection, parameter definition, installation and commissioning, technical training, after-sales support, overseas services, etc., comprehensive and one-to-one. In this way, we can ensure that our equipment reaches the customer's production standards in the shortest time.

In view of the particularity of the foreign market, our magnetic card punching machine meets the global voltage change and safety requirements and meets the CE and FCC standards. In addition, we also provide 24-hour overseas after-sales service and guarantee the replacement of core components so that customers can rest assured.

Soft magnetic card products are competing in the global market, and magnetic card punching machines with higher production efficiency are needed. Stable performance, a wider range of functions, more applications, a guarantee that products meet the established quality standards, and help for enterprises to expand their market share. Regardless of the size of the enterprise, whether it is a small and medium-sized enterprise that produces personalized products or a large-scale manufacturer of a certain card, the machine with key parameters such as accurate punching, automatic feeding and unloading, intelligent sorting, and multi-functional instantaneous switching has the competitive advantage of cost control and efficiency maximization.