The paper winder features an innovative modular changeover system. This breakthrough system allows operators to independently change winding configurations with minimal instruction, significantly increasing the flexibility of the production system. Each change does not require expensive on-site technicians. This change for production employes has helped the company improve profitability by reducing downtime.

Posters are prone to wrinkles and uneven edges during the winding process due to their size and paper thickness. The poster rolling machine adopts a specific preset rolling mode. The winding tension is monitored in real time by the intelligent tension sensor to ensure that it is controlled within the range of 0.5-1.0N. At the same time, it has a synchronous conveying mechanism driven by a servo motor to ensure the constant winding speed and conveying speed. The maximum winding speed is 15m/min. After switching to this mode, the operator selects "Poster Winding" on the equipment touch screen, and the system loads the preset parameters. The whole switching process only takes 30 seconds, and it can adapt to common poster substrates including coated paper and matte paper.

The learning card is small and hard, and the requirements for winding accuracy are higher to avoid winding deviation and edge damage. To solve this problem, the winding method of the learning card paper winding machine adopts a high-precision positioning system and integrates a CCD visual inspection system. The system tracks the edge position of the material in real time, and automatically corrects the conveying path when the deviation exceeds 0.1mm. In addition, considering the high rigidity of the learning card, the system sets the winding force between 1.0 and 1.5N to achieve a balance between tight winding and substrate protection. In this system, the operator switches the mode to the specific size of the learning card and enters the width and length. The system automatically selects the best winding parameter scheme, which can adapt to a variety of learning card sizes from 50mm×80mm to 200mm×300mm.

In the winding industry, some materials are particularly difficult to handle. These materials include plastic films, EVA and fabric composites. This is because they are made of layered materials and have different thicknesses. To solve this problem, the composite material adaptive winding system came into being. It uses multiple sets of sensors to monitor key winding parameters such as material thickness, tension, and temperature, and feeds them back to the central computer control system for real-time adjustment. The control system automatically adjusts the winding pressure and speed according to the material characteristics. For example, when winding EVA composite material, the system controls the temperature at 25-30℃ to prevent high-temperature deformation, and adjusts the winding speed to 8-10m/min to prevent the composite layer from delamination. In the winding composite cloth mode, the system can store the parameters of 10 kinds of composite materials, which is convenient to use and efficient in design.

When the paper rolling machine is used for materials of different types and thicknesses, its precision comes from three basic design concepts, and the complete technical guaranty is composed of mechanical frame, intelligent control, power system and other aspects.

The paper rolling machine adopts adjustable winding roller structure design, and the diameter of winding roller can be freely adjusted within the range of 50mm-150mm to meet the winding requirements of different diameters. In addition, the feed inlet has a lifting and lowering material pressing mechanism, which can automatically adjust the height according to the material thickness (0.01mm-5.0mm) to ensure continuous material feeding. For different types of substrates (paper, plastic, composite materials), the equipment allows the replacement of different materials of the winding roller sleeve (rubber sleeve, silicone sleeve) to prevent the substrate from being worn or adhered.

The PLC intelligent control system independently developed by the paper rolling machine integrates three control systems of tension control, speed control and positioning control. The tension control adopts closed-loop feedback control mechanism, adjusts the output control in PID algorithm, the tension control precision is ±0.05N, and the tension is actively controlled in the winding process. The speed control is driven by a servo motor, the adjustable speed range is 1-20m/min, and the adjustment accuracy is ±0.1m/min. In terms of positioning control, the combination of CCD visual detection and laser positioning system is adopted to ensure the edge alignment accuracy of the winding material is within 0.1mm. All three systems have achieved the specified winding control.

The paper winding machine is also equipped with a servo motor, with a power range from 0.75kW to 3.0kW, which can be flexibly adjusted. For example, when winding thin plastic film, a low-power motor of 0.75kW can meet the operation requirements, saving energy and improving efficiency. When winding thick and heavy composite materials, the high 3.0kW power motor ensures sufficient power output. At the same time, the motor adopts frequency conversion, which can automatically adjust the power output according to the load, without manual intervention, and save energy when there is no winding.

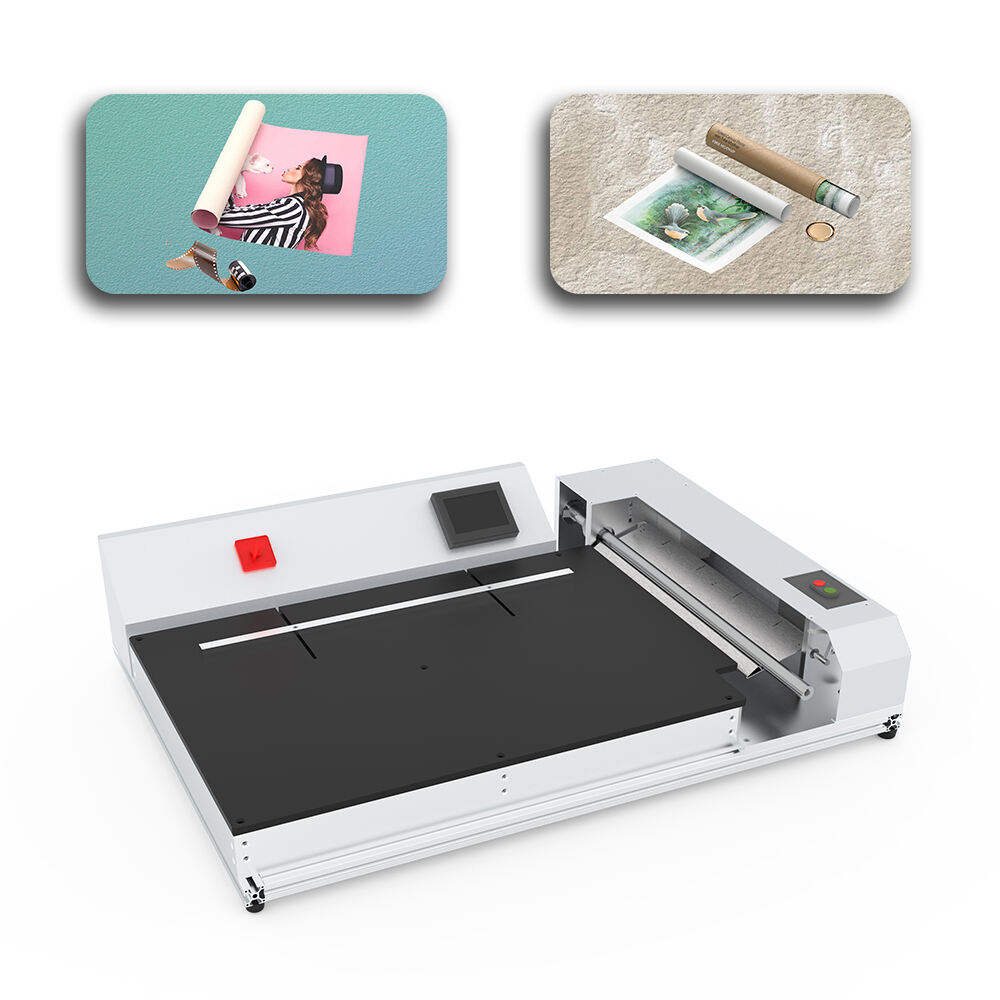

A large packaging company in Southeast Asia provides packaging solutions for food, electronics, toys, etc. They produce and supply a wide range of packaging products, including posters, fliers, flash cards and laminated packaging films. To meet the different needs of production, the company previously had three different winding machines, which were used as winding machines for paper, plastic film and composite materials respectively. However, this practice has high production costs, occupies a large production space, and requires the employment of skilled personnel to operate the winding machine, which increases the management burden.

The company put this multi-functional roll paper machine developed in Shenzhen into use from 2024. This machine has completely optimized the production mode. Thru the machine's programmable mode switching, one machine can now complete the rolling operation of a variety of products such as posters, teaching cards, and composite packaging films. Two old machines were directly eliminated, the production area was reduced by 40%, and the equipment procurement funds were saved by about 600,000 yuan. In terms of machine function, the system is fully automated, the production process does not require manual monitoring, and the output of the entire shift has increased by 60%. In addition, the rolling process that used to require five operators now only needs one, who only needs to supervise the machine and clean up the process. This has reduced labor costs by 80%.

The production manager said, "We value the versatility of the paper winding machine. They can precisely wind thin plastic films of 0.02mm and EVA composite materials of up to 3mm in thickness. And they are very easy to use. New employes can confidently use the machines after just one day of training, which helps to reduce our training costs. In the first six months of owning the machines, our first-time pass rate for products increased from 92% to 99.5%, and customer complaints decreased by 80%. During the same period, our order volume also increased by 30%. This helped us improve our technical capabilities as we started to target overseas markets."

Faced with fierce competition in the global printing and packaging market, the demand for efficient, precise and multi-functional production machinery has increased significantly. This in turn has increased the importance of machinery as a core competitiveness of enterprises. The paper rolling machine introduced by Shenzhen breaks thru the efficiency bottleneck thru high automation, ensures quality thru precision control, realizes flexible production thru adapting to a variety of products, reduces management costs thru simplifying operation control, and meets the production needs of overseas markets thru adapting to single-sheet and multi-sheet paper rolls.

As a Chinese company engaged in the research and development of winding equipment, it has exported its paper winding machines to more than 30 countries in Europe, America, Southeast Asia and other regions, and has cooperated with thousands of printing and packaging companies by virtue of its high attention to technological innovation and its understanding of overseas market demand. Next, the company will continue to focus on technological upgrading, develop more paper slitting machine equipment suitable for other industries, help global packaging companies achieve cost-effectiveness goals, and occupy a more favorable position in the global market.