The competitiveness of the poster paper winding machine for materials such as posters depends on the winding quality. This article will explore how overseas Shenzhen equipment packaging machinery suppliers can help with the pain points of winding from the five key aspects of winding.

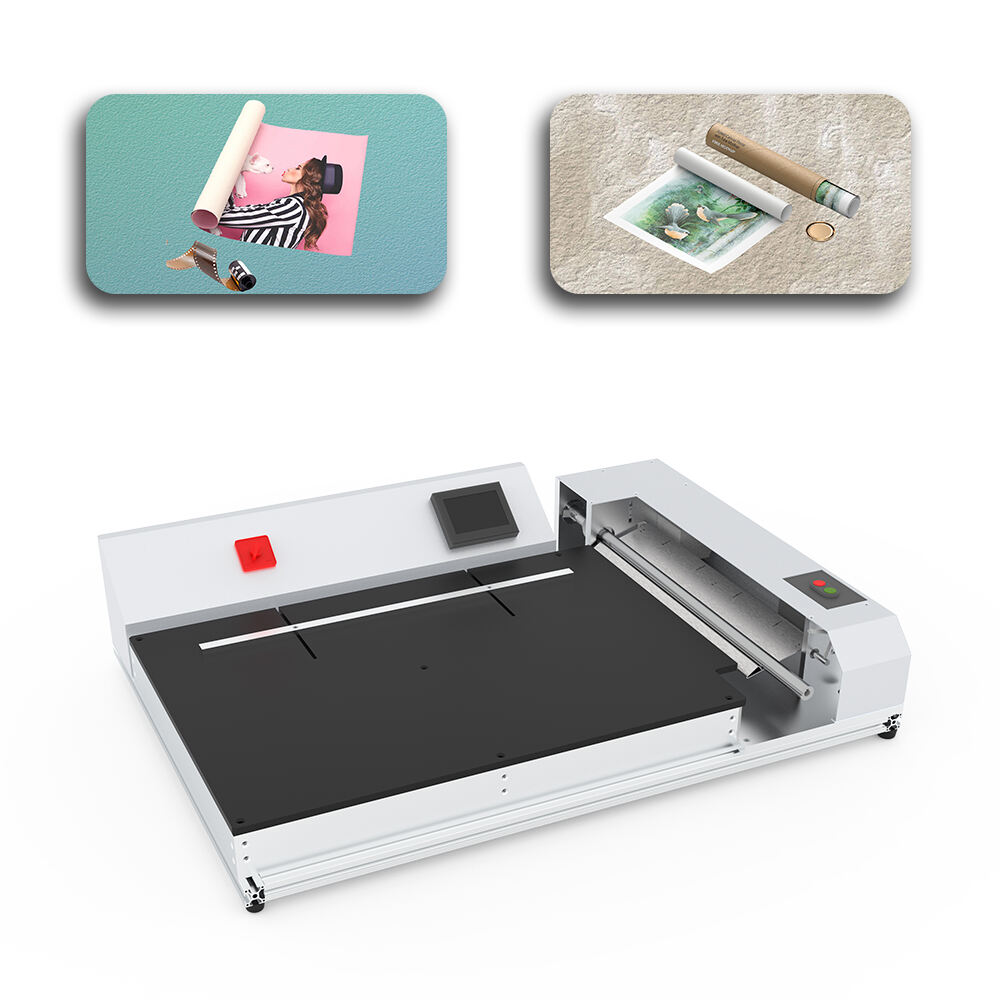

The poster paper rolling machine provides a single-sheet or multi-sheet synchronous operation solution for the rolling of poster paper, film, and other packaging materials. Automation, high control, and high efficiency solve the problems of poor esthetics, low quality, and high cost of manual paper rolling.

The versatility of the equipment requires adaptation to the pretreatment of materials. To avoid paper wrinkling and embrittlement, the moisture content of 5%-7% should be maintained during pretreatment. Check whether the surface defects, width, thickness, etc. of the film and composite material are uniform. When the sheet is wound in layers, it should be positioned, aligned, and over-relaxed to facilitate the adjustment of subsequent processes.

In the initial stages, the versatility of the rollers and the diverse qualities of each material should be considered. Customized guidelines should be developed for each stage of the process for different material types. For different grades of paper used in printing packaging, the moisture content should be checked to ensure that it is within the acceptable tolerance range of 5%-7%. This will avoid the paper having too much moisture, which can cause wrinkling after winding, or too little moisture, which can cause the paper to crack. For composite materials such as plastic film, check the surface for scratches, damage, stains, etc., and whether the width and thickness are uniform to ensure that the materials entering the winding process are within the range of the equipment. In addition, for the winding of multiple materials, the materials should be placed neatly in the order of entering the equipment to improve efficiency and reduce the possibility of rework.

Equipment debugging: check the parallelism of the take-up roller, the pressure of the pressure roller, and the transmission lubrication. The automatic feeding and positioning are debugged, and the feeding accuracy of PLC calibration is within ±0.1 mm. Set the parameters, run the machine without load, and put it into production after confirming that it is normal.

Environmental requirements: clean, dry, temperature 20-25℃, humidity 50-60%.

The key to precise winding: the initial adjustment of thin film or light paper is 0.5-1 N to prevent stretching, and the adjustment amount increases as the winding diameter increases. The initial tension of EVA and other thick materials is 1.5-2 N, and the tension sensor monitors in real time, and the deviation is automatically adjusted, and the balance is within ±0.2 N.

For light and thin paper or thin plastic film, the initial tension must be set low and should not exceed about 0.5-1 N so as not to cause tensile deformation of the film. As the winding proceeds, the increase in tension is to alleviate the problem of inconsistent tightness of the inner and outer layers of winding. For thicker composite films such as EVA, the initial tension can be appropriately increased to about 1.5-2 N. In addition, the equipment also monitors the tension through the tension sensor to improve the automation performance. When the tension deviation reaches ±0.2 N, the system automatically corrects the output of the magnetic powder brake to maintain dynamic balance.

The equipment is designed with multiple independent tension adjustment modules to solve the problem of uneven tension distribution in the width direction of the material and alleviate problems such as wrinkling and slack. The touch screen interface retains the tension curves of commonly used materials, and calling these curves can greatly improve the operation efficiency.

For neat and beautiful winding is the core demand of our customers. The control is achieved through alignment accuracy, speed matching, real-time monitoring, etc. This is where the equipment is superior to manual winding.

The photoelectric deviation correction device determines the edge alignment accuracy, and the accuracy is 0.05 mm. When the edge deviation is greater than 0.1 mm, it will be adjusted automatically, and the edge error is ≤±0.2 mm. When multiple sheets are wound, the system's multi-axis synchronous control is used to ensure the balance of feeding speed and tension and prevent deviation.

Matching speed and acceleration is the key to ending flatness: the speed of thin materials is set to 15-20 m/min, and the speed of thick composite materials is set to 8-12 m/min. This control takes into account both efficiency and the quality of the composite material while gradually accelerating from 5 m/min to a maximum of 30 m/min at the beginning and decelerating 50 mm before the end.

The visual inspection system can monitor the flatness of the product in real time. When an abnormality occurs, the system will alarm and stop running. The operator regularly confirms that the end face runout is ≤0.3 mm, which meets the foreign acceptance standards.

Standardized operations take automation to the next level but must be accompanied by maintenance to ensure the safe and stable operation of the system and prevent the system automation from having uneven efficiency.

In terms of efficiency, we have implemented process automation to minimize human involvement in order to improve efficiency. After the process is automated, the system parameters not only track the progress but also evaluate the qualification rate. The daily output of a machine is 8 to 10 times that of manual production. The system also allows up to three different materials to be wound simultaneously, further increasing productivity.

The equipment is installed with an emergency stop system, a fence, an infrared hand guard, and other functions. At the same time, the equipment maintenance implements the "daily inspection, weekly maintenance, monthly repair" system, checking the accuracy of the sensor and the oil level every day, cleaning the dust and checking the belt every week, and checking the wear of the roller and replacing the aging parts every month.

The first inspection of finished products is directly related to quality. There must be a standardized, documented process, including traceability, to establish the quality of the delivery.

The inspection process checks for wrinkles, scratches, and whether the end face is flat and the flatness is within ±0.3 mm. The diameter and width are measured with calibrated tools, and the variation range is within ±0.5 mm. Performance evaluation is based on the material, such as tear resistance, sealing, etc. Qualified products are put into the warehouse, and unqualified products are analyzed, traced, and rectified.

The intelligent system provides automatic traceability of finished product batch codes, and customers can query complete production data. For overseas customers, we provide remote technical support and use IoT functions to assist in real-time troubleshooting and maintenance.

Because winding control is a systematic project, the quality and benefit of the winding control process are determined at every step. Shenzhen suppliers use winding control systems and poster paper winding machinery to combine scientific control and poster paper winding machinery to provide cost-effective solutions for global customers. For a given industry, production upgrades are possible as long as the proper tools and a solid understanding of key control points are available.

If your business is related to printing and packaging, stationery, composite material processing, or other industries, then a professional poster paper roll machine and mechanical production are essential support.