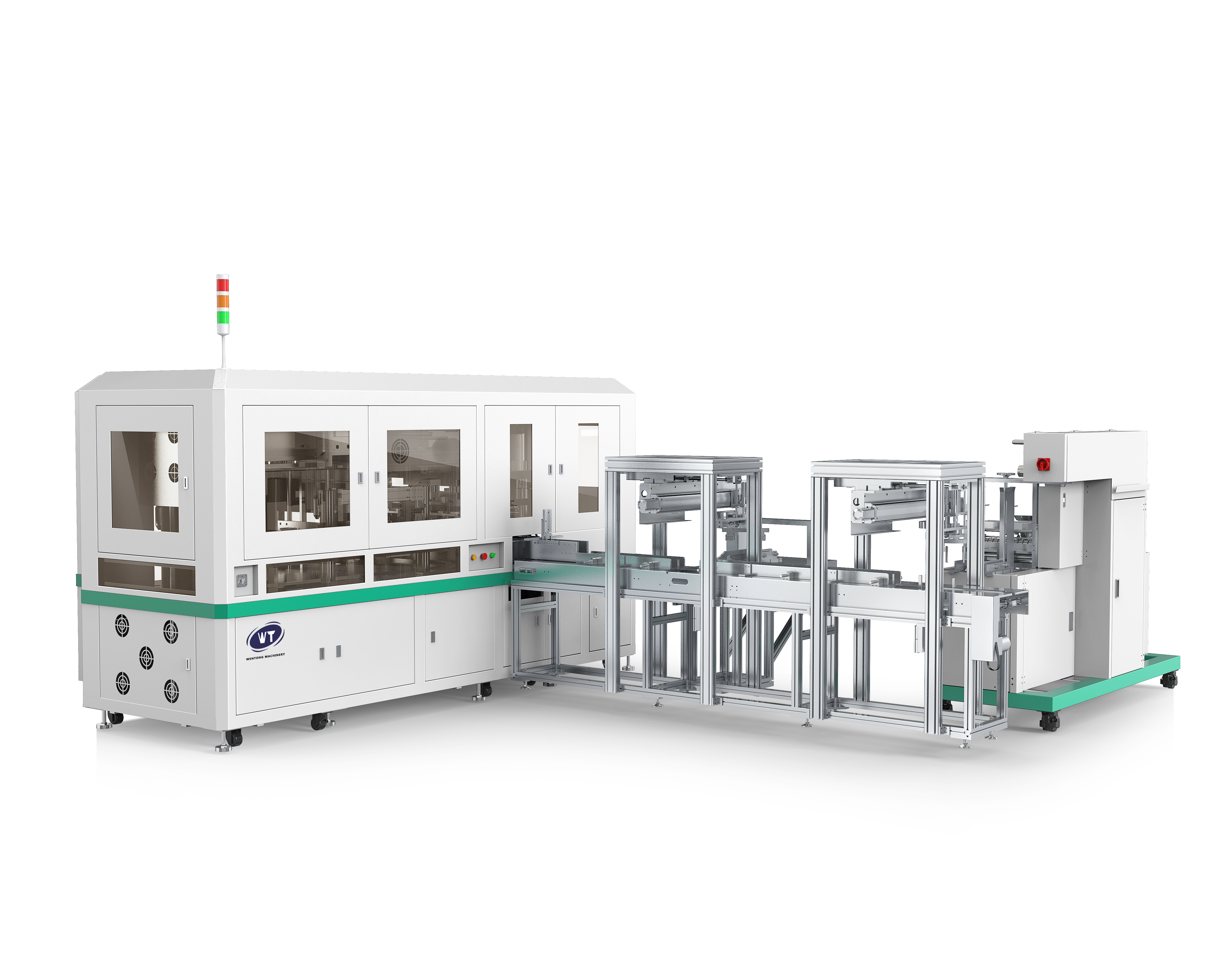

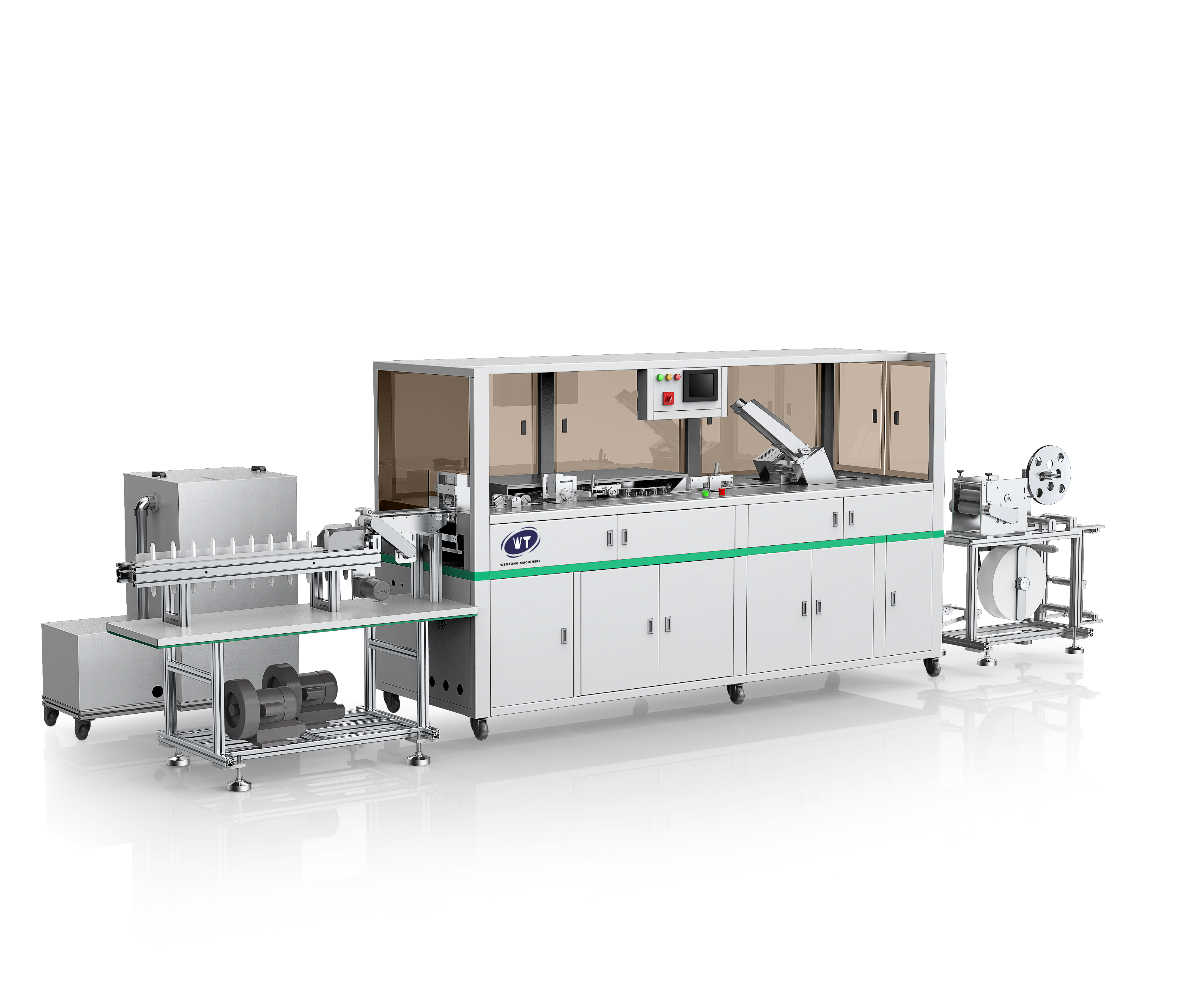

Wentong Machinery’s automatic card machines represent the pinnacle of efficiency and automation in card production, integrating multiple processes into a single streamlined system. These fully automated solutions, such as the WT-ACM series, can handle the entire card-making workflow—from paper feeding and folding to creasing, trimming, and even finishing—with minimal operator intervention. The core technology includes a servo-driven multi-axis control system that coordinates each stage with millisecond precision, ensuring seamless transitions between functions. For example, the automatic card folding and trimming machine can produce 400+ cards per minute, with each card undergoing quality checks for fold accuracy and cut precision. The machine’s modular design allows for easy integration of optional units, such as embossing stations, foil stamping modules, or UV coating systems, enabling clients to add premium finishes without additional equipment. Wentong’s automatic card machines feature intelligent diagnostics that detect jams or errors in real time, displaying troubleshooting steps on the HMI interface to reduce downtime. Built with corrosion-resistant stainless steel components and IP54-rated enclosures, these machines thrive in both dry and humid environments, making them suitable for global deployment.