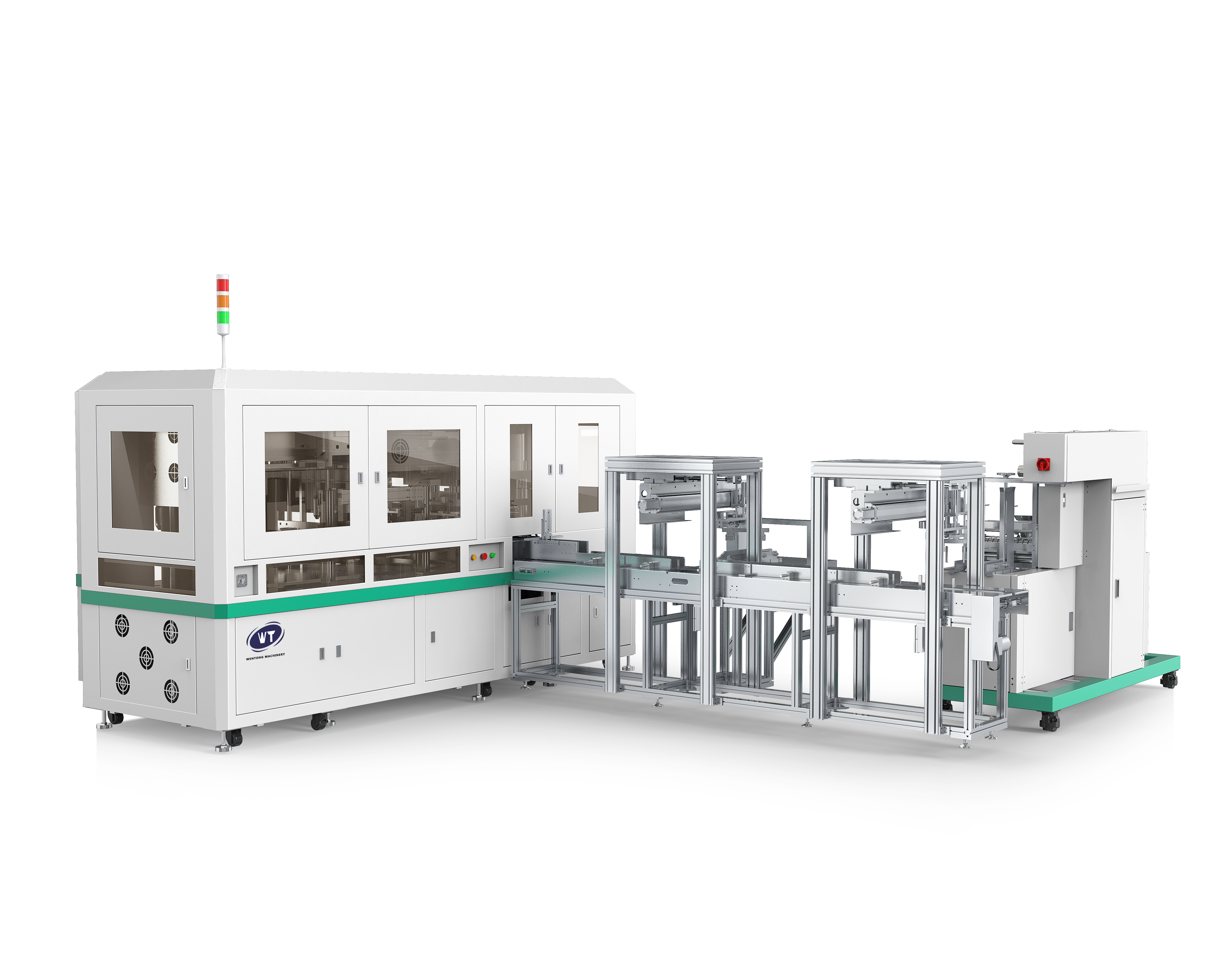

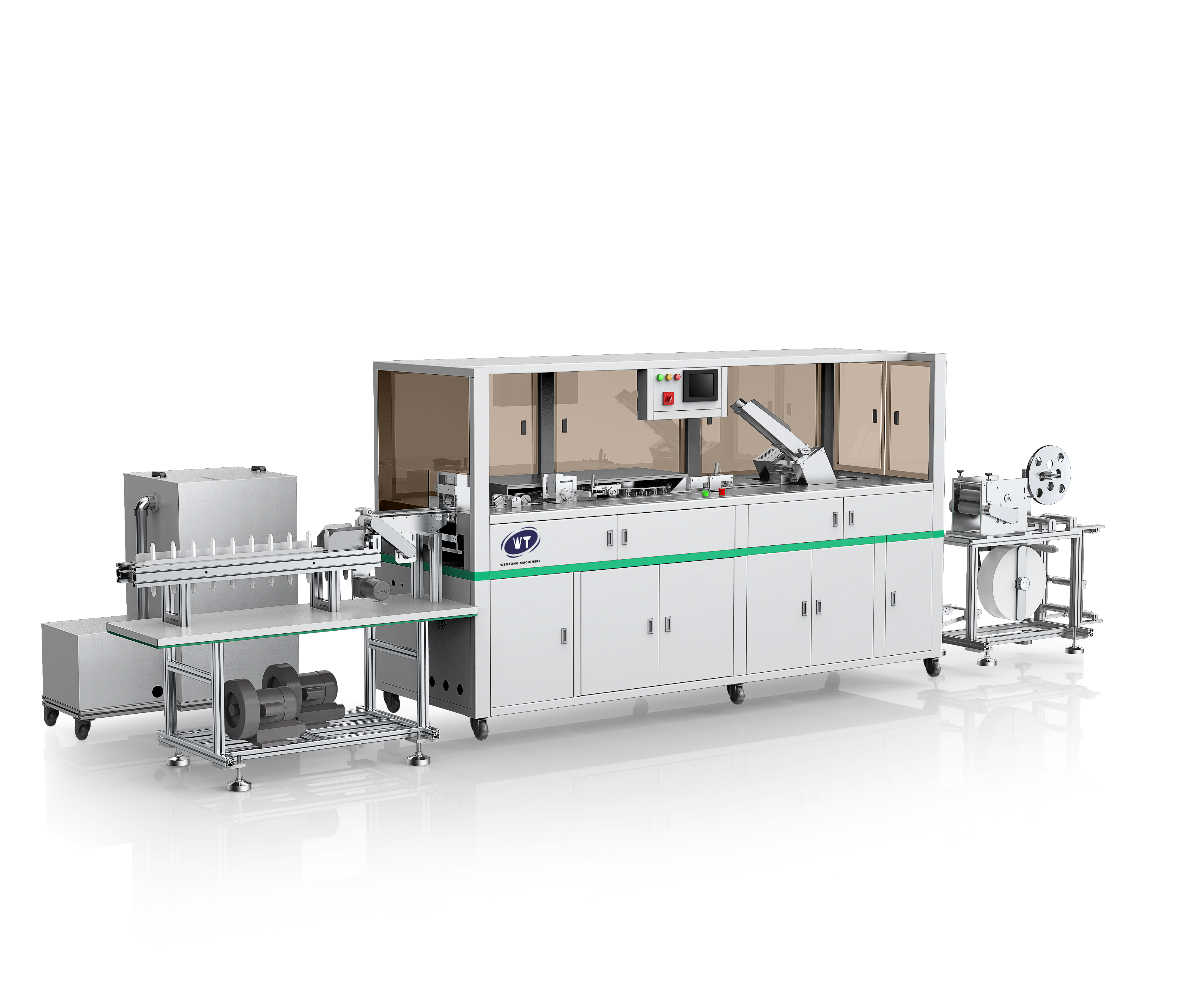

The card punching machines from Wentong Machinery are specialized tools designed to create precise holes and shapes in various card materials, catering to applications like ID cards, gift cards, and ticket production. These machines utilize high-strength punch dies made from SKD11 tool steel, heat-treated to 60HRC for durability, capable of punching through 2mm-thick PVC cards or 350gsm paper without deformation. The WT-CPM series features an adjustable punching table that can accommodate multiple card sizes simultaneously, with positioning guides that ensure hole placement accuracy within ±0.2mm. For enhanced productivity, automatic feeding models use a conveyor belt system to transport cards through the punching station at speeds of up to 200 cards per minute, while manual models offer flexibility for small batches or custom designs. Safety features include a dual-hand activation system and emergency stop buttons to prevent accidents, while a built-in waste collector keeps the work area tidy. Wentong’s card punching machines also support specialized punching needs, such as rounded corners, slot holes for lanyards, or custom die-cut shapes, with quick-change punch sets that allow operators to switch between designs in minutes. The manufacturer provides comprehensive die maintenance kits to extend the lifespan of punching components, ensuring long-term cost efficiency for clients.