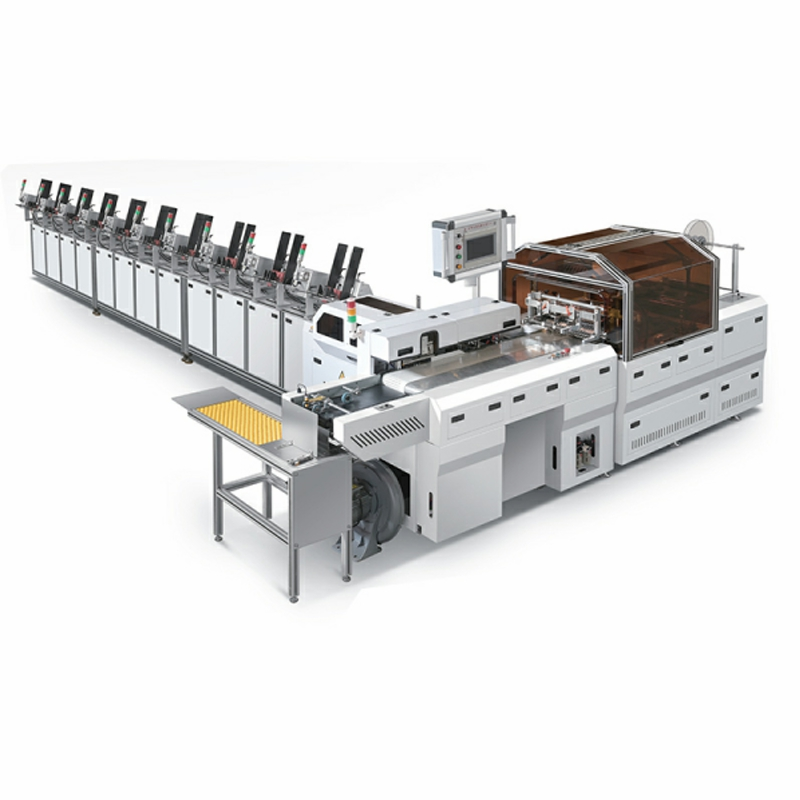

Our bounded collating devices aid those whose work entails collating cardboards. Whether it is assembling the constituents of large box cardboards or smaller cutouts of cardboards used for furniture, these devices ensure precise ordering of every piece of cardboard. They automate and organize in the right order. These devices are built to endure the mechanical abuse wrought on tempered cardboards. The robotic control systems allow modular customization of programmable collating patterns making tailoring ease of servicing versatile for different production needs. The workflow processes of a cardboard processing manufacturer designed around these machines will have more efficient production and quality standards.