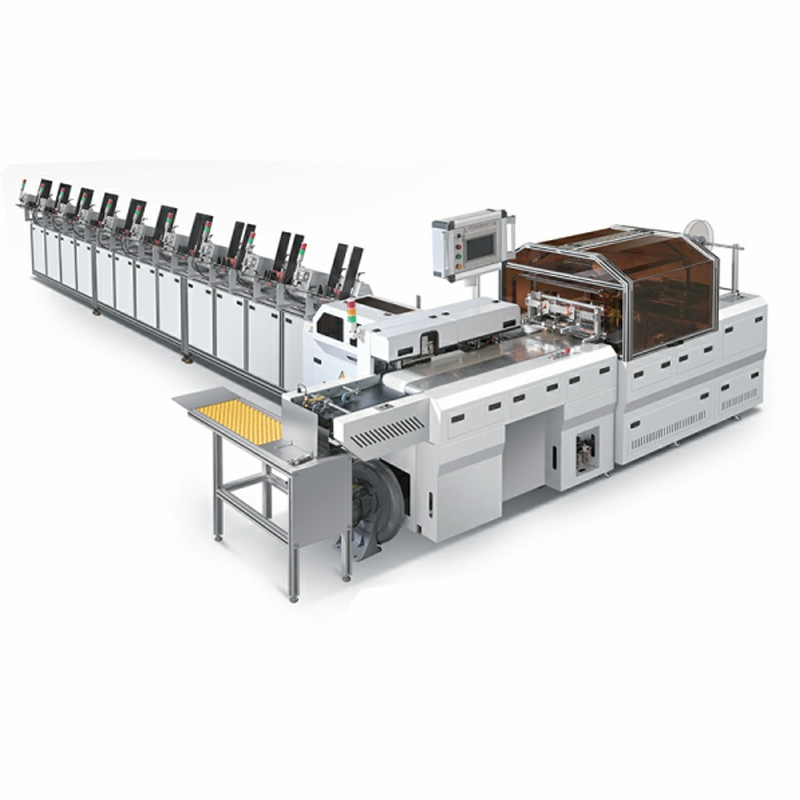

Its use in crafting and printing makes cardstock popular. Additionally, our die cutting machines work flawlessly with them. These machines are equipped with sharp blades that can cut intricate patterns which adds uniqueness to the crafts. These machines perform multiple types of cuts. Everything is possible from basic shapes to more intricate ones. These machines are perfect aids for making scrapbook pieces and greeting cards. They contain adjustable settings which provide the adequate amount of pressure for the thickness of the cardstock.