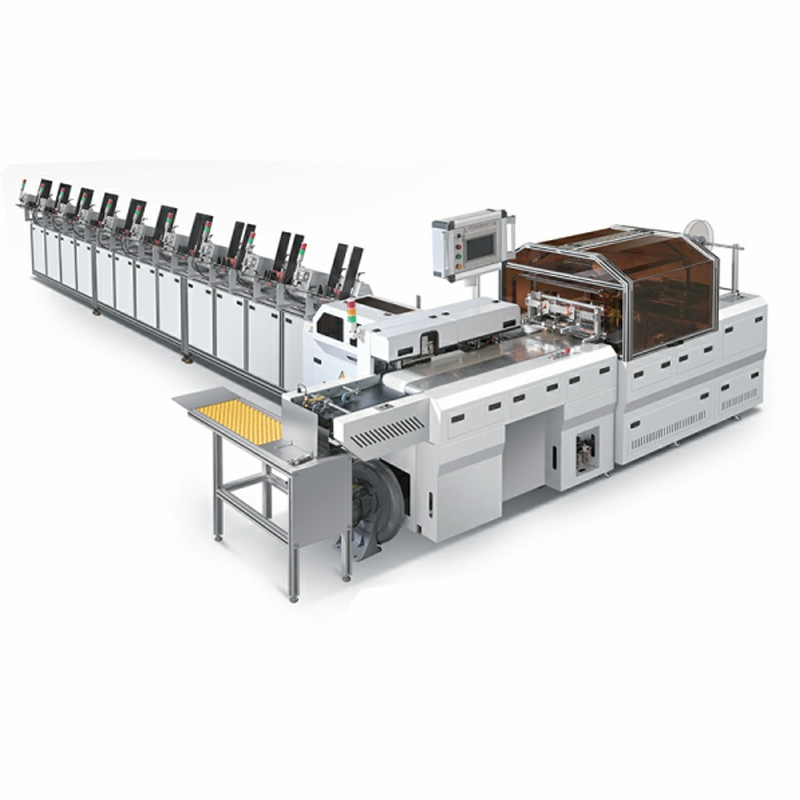

End User - Friendly Operation for Ease of Use

User Friendly Operation, Easy Work Steps: We know that in a modern workshop everything needs to be effortless to increase efficiency. Ease of access is complementary to how well these die cut machines deliver operator productivity. Each and every control is properly arranged for all operators and all levels of skills. Easy adjustments and job setting can be done through the touch screen control panel which works like a computer. With the low operational experience, operators can be trained to use the machines in a few sessions and fully understand their inner workings. Of course, the machines come with detailed manuals and user guides that can easily be accessed on the internet. Maintenance and upkeep of the machines is quite simple due to the straightforward structure of the components and cleaning needed to be performed which does guarantee the optimal working state of the machines, lower overall maintenance required, and decreased downtimes.