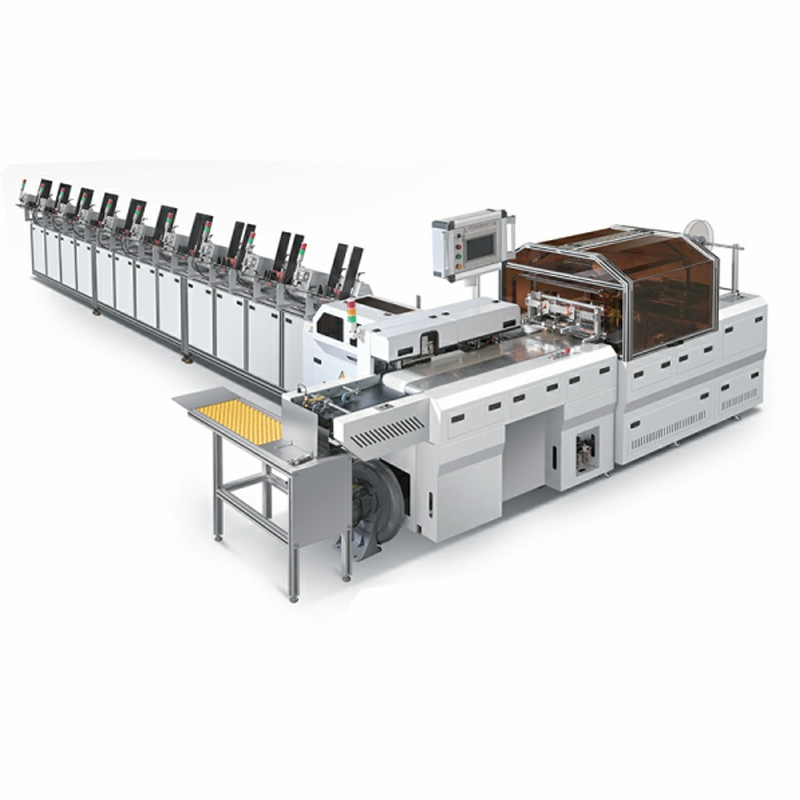

Ultra - High Speed Performance:Maximizing/ Enhancing Productivity

Maximizing Output Without Sacrificing Efficiency: Our die cut machines offer remarkable high-speed operation. Their robust mechanical structure coupled with optimized drive systems allows them to process materials swiftly, increasing production throughput significantly. In busy card production or their printing and packaging downstream, these machines process large-scale orders in record time, meeting tight deadlines and boosting productivity. Cutting speed does not compromise cut quality; pieces are consistently and accurately cut, making them an indispensable asset to businesses competing in today's fast-paced economy.

These machines are making it possible for packaging and printing businesses to effortlessly keep pace with growing demand.