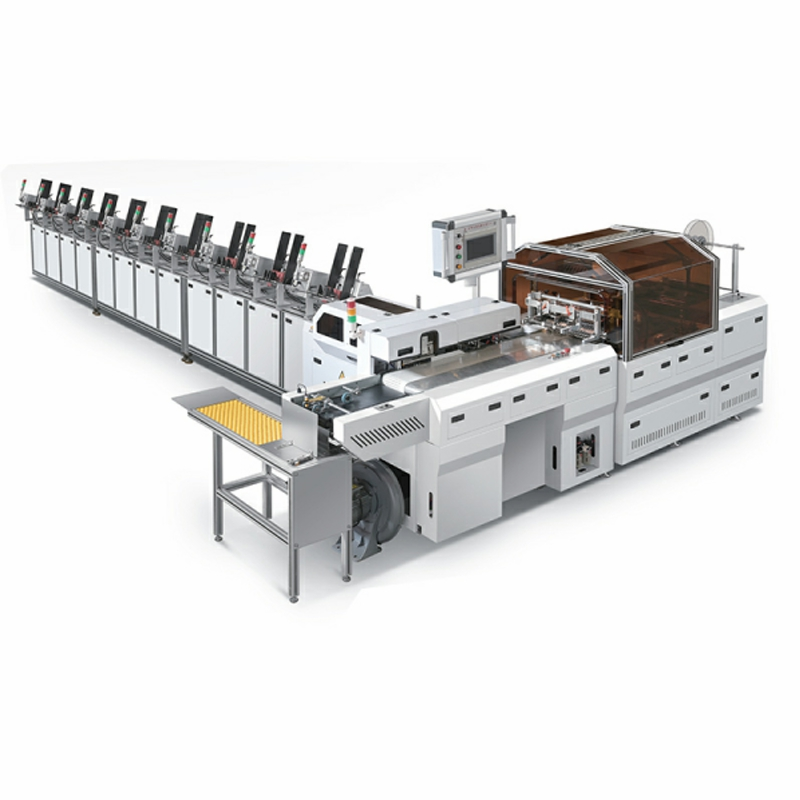

Shenzhen Wentong Machinery Co., Ltd. offers efficient paperboard collating machines that are designed to streamline the collating process of paperboard materials. These machines are capable of accurately and quickly collating multiple sheets of paperboard, improving the production efficiency and reducing the labor intensity. The paperboard collating machines feature a compact and sturdy design, which allows them to occupy less space while maintaining high performance. They are equipped with advanced detection and alignment systems, ensuring that the paperboard sheets are collated in the correct order and position. The company's paperboard collating machines are easy to adjust and maintain, making them suitable for various production environments. Whether it is for small batches or large-scale production, these machines can effectively meet the collating needs of customers, helping them improve the production efficiency and product quality.