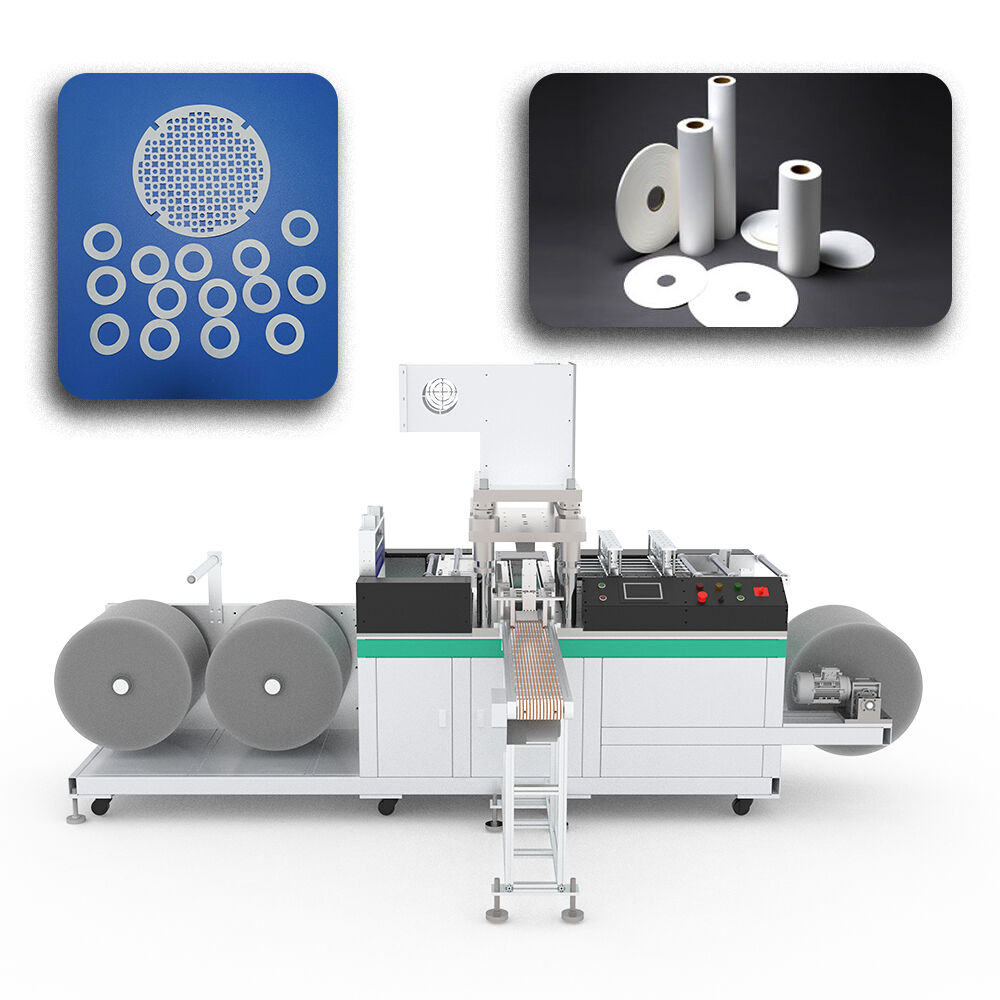

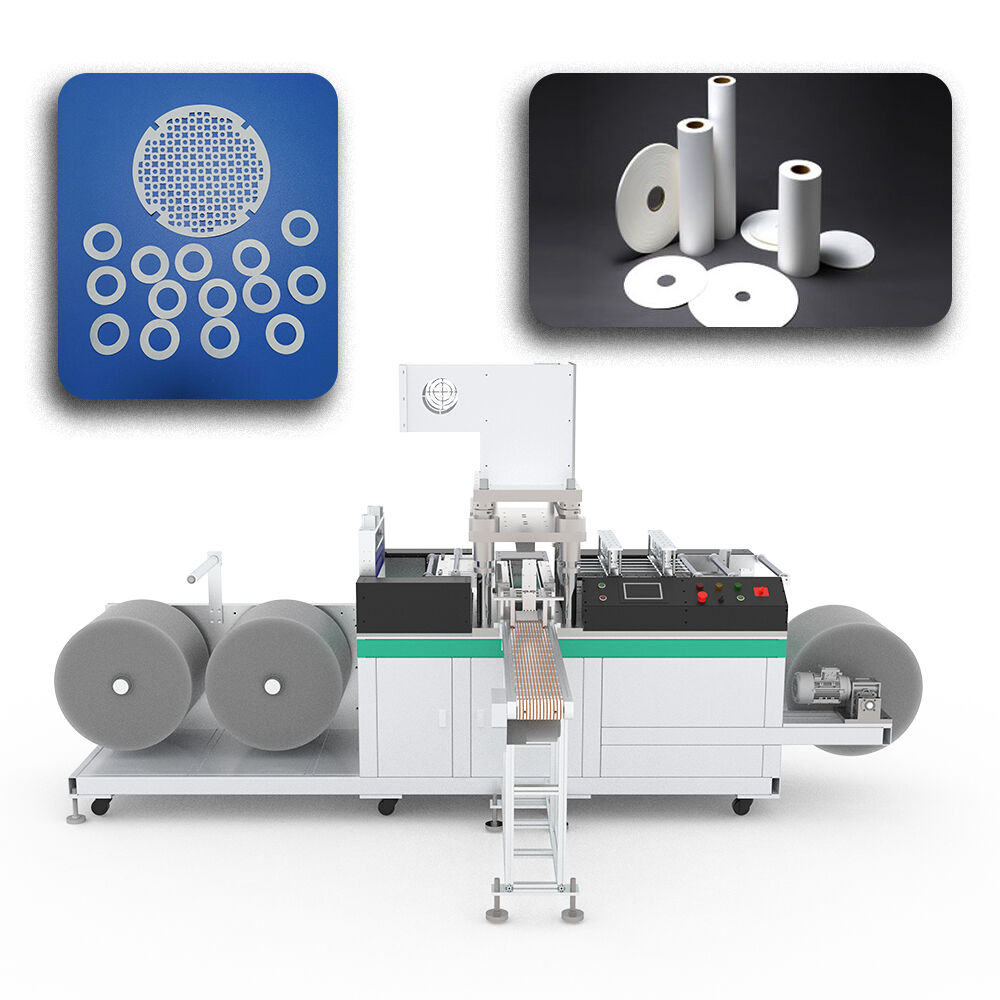

The filter ring paper die-cutting machine is very professional industrial equipment. Its main purpose is to quickly and accurately meet the strict cutting standards of various special paper products, including silicone oil paper, filter paper, steamer paper, coated paper and non-stick oil paper pads. The equipment is used directly for the large-scale and highly consistent production of the following important products:

-

Precision filter components: The filter ring paper die-cutting machine produces various precision filter components, such as filter paper rings, filter paper cores, and round filter paper. These products are the most important components of air purification systems, medical filtration equipment, industrial oil filters and automotive filters. The filtration efficiency, flow resistance, equipment life and other parameters depend on the accuracy of its size and edge. The finished product after stamping has smooth edges, no burrs, no fibre shedding, and the terminal filtration performance is stable and reliable.

-

Food-grade safety pad material: Food-grade safety pad: Packaging materials that directly contact food, such as silicone oil paper for high-efficiency processing and baking, steamer paper, and non-stick oil paper pads. The tool keeps the area clean while punching and cutting so that the final product meets the FDA, EU and other international food contact material regulations and standards. At the same time, the mould meets the customer's ultimate goal of product specifications, cutting shape, and cleanliness standards.

-

Special industrial paper products: suitable for making laminated paper rings, composite paper pads, insulation pads, etc. These materials often have special coatings, composite layers or porous structures, which make it more difficult for the equipment to control pressure, feed accurately and match moulds.

2. The filter ring paper die-cutting machine has ten key technologies and performance advantages.

-

1.Unique structural rigidity design, stable texture: the main body of the equipment is made of dense cast iron, which is formed at one time by the CNC machining centre. The grid ribs strengthen the key load-bearing parts, and the centre of gravity of the machine is carefully calculated and set. This basic design makes the equipment feel stable and vibrate little when working. It also provides a solid mechanical platform for maintaining the punching and repeated positioning accuracy of micron level (±0.05 mm) for a long time and fundamentally avoids the accuracy loss caused by the deformation of the frame.

-

2.Excellent durability and ultra-long life cycle: The core stamping unit is made of imported high-strength alloy steel and is vacuum heat-treated, deep-cooled and precision-ground. It is very durable and has a very long service life. Rockwell hardness can be up to HRC58-62, with extremely strong wear resistance. The lead screw and guide rail of the main gearbox adopt heavy-duty brand components, and the design life is at least 80 million strokes. The equipment can run continuously for more than 20 hours per day under normal working conditions, and the annual average overall failure rate is less than 1.5%. This reduces maintenance costs and the chance of production stoppages.

-

3.High production flexibility with one machine for multiple uses: This filter ring paper die-cutting machine has powerful function expansion capabilities, so it can be used for many different purposes. The patented modular die quick-change system allows operators to switch the line from making filter ring paper to stamping and cutting ordinary paper products such as book card paper and gift tags in less than 30 minutes. This flexibility allows manufacturers to handle a variety of orders with one piece of equipment. It is especially suitable for small-batch, multi-variety, customised production tasks, which greatly improves the return on investment and market response capability of the equipment.

-

4.Integrated online hot stamping process: The machine can be equipped with a high-precision hot stamping unit, which can realise two processes of cold stamping and hot stamping. The module can be synchronised or unsynchronised with the die-cutting action and can accurately transfer the logo, text or decorative pattern to the surface of the paper pad, filter paper outer ring, etc. This function combines the original process that required two devices and two procedures into one. This not only makes production more efficient (expected to increase by more than 30%), but also avoids errors in handling and alignment in the intermediate links, greatly improving the overall grade of the product and brand awareness.

-

5.Mature and reliable full servo drive technology: The power core of the equipment adopts a high-performance 7.5 kW AC servo system drive, which is a mature and reliable full servo drive technology. It has the advantages of accurate speed and position control, fast response, and a remarkable energy-saving effect (overall energy saving of about 25% to 40%). The servo system directly controls the depth and pressure curve of the punch. It can also automatically adjust the punching settings according to different types and thicknesses of paper, from ultra-thin silicone oil paper (0.05 mm) to composite filter paper (3.0 mm), ensuring that each punch is clean and neat.

-

6.Deeply integrated customised overall solution: We provide all-round services from process analysis to production support as part of our deeply integrated customised overall solution. We can customise the feeding mechanism, mould design, finished product collection method, etc. to meet the special needs of customers, such as Teflon coating, high elastic fibre, unique finished product shape, and docking with upstream and downstream production lines. For example, the ion wind feeding system is designed to solve the problem of electrostatic adsorption, and the robot material taking interface is designed to cooperate with the automatic assembly line.

-

7.Intelligent automatic sorting system: The equipment has or can have intelligent sorting modules using machine vision and sensor technology. The system can detect the quality of stamping parts in real time online and automatically sort and classify the finished products according to the preset rules by using robots, turning platforms or airflow channels. There are different modes, such as:

-

8.Sequential collection: The sorted material flow is immediately handed over to the automatic winding and stacking process in the order of product demoulding.

-

9.Collection by quality or specification: automatically separate good products from bad products, or put products of different sizes and shapes into different collection containers. This function makes manual sorting a thing of the past and makes product traceability possible.

-

10.7.5KW large torque servo power guarantee: The high-power servo motor is adopted to ensure that sufficient, stable and instantaneous punching power can still be provided when punching high-density and multi-layer composite filter paper. The "cut-through" or "pull" phenomenon caused by insufficient power is avoided. Its precise torque control also ensures mould safety and extends its service life.

-

11.Different collection methods for customised finished products: We provide flexible finished product output solutions to meet the needs of different post-packaging or assembly situations:

Sequential stacking: Standard count packaging uses sequential stacking.

Rotary compartment hopper: Automatically separates different products when different products are manufactured in the same stamping cycle.

Vacuum adsorption conveyor belt: it can convey very thin and easy-to-drift materials without damaging the materials.

Direct connection to the packaging machine: makes the entire production line fully automated from die-cutting to packaging.

-

12.The precise and burr-free punching process is achieved by the combination of three technologies: "punching depth servo closed-loop control", "dynamic pressure compensation" and "micro-gap fine grinding die". The angle and clearance of the die-cutting blade are set to best match the different lengths of pulp fibres and coating types. This physically prevents the formation of burrs. The edges of the finished product are inspected under a microscope, and there is no visible fibre warping, which meets the stringent standards of high-end application scenarios.

3. Market positioning of filter ring paper die-cutting machine

The equipment is correctly positioned as a major player in the global industrial supply chain, mainly serving:

-

Filter and filtration system manufacturers: Tier 1 or Tier 2 suppliers of precision stamped parts for core filtration media worldwide. The high precision, automation, and burr-free features of the equipment enable it to meet the strict quality standards of OEMs.

-

Food packaging and processing enterprises: provide safe lining materials for global chain baking brands, food processing plants and packaging enterprises. Hygienic design of equipment, rapid production capacity and hot stamping value-added capacity are all good ways to enter the international market.

-

Special industrial material processor: produces precision washcloths for the electronics, home appliance, mechanical seal and other industries. The equipment is able to handle a wide variety of orders with short delivery times, mainly because it can produce a wide range of products and can process composite materials.

-

Factories committed to automation upgrades: for manufacturers facing rising labour costs and quality consistency issues, these devices are a big step toward replacing manual labour, obtaining production data and moving toward "smart factories".

Conclusion

The filter ring paper die-cutting machine is a microcosm of the technical strength and market insight in the field of high-end special equipment manufacturing in Shenzhen, China. With strong mechanical engineering capabilities, intelligent automation integration capabilities, in-depth customised service capabilities, and a deep understanding of filter paper product technology, it provides reliable, efficient, and forward-looking production solutions for global customers. Choosing this equipment means higher product qualification rates, lower product life cycle operating costs and stronger market competitiveness. Companies should make long-term investments in precision paper product processing to gain an advantage over their competitors.