The cutting machine is the most important equipment for making cards, smart cards, game cards, etc. Its technical level directly affects the production accuracy, texture and speed. Die-cutting machines have been keeping up with the changing needs of the industry. From the initial simple machines that required manual operation to today's intelligent machines that have both numerical control technology and Internet of Things technology. This article will review the development history of die-cutting machines and look forward to the innovation direction of die-cutting machines from three aspects: technology iteration, intelligent monitoring, and environmental protection. And in combination with its main application characteristics, it provides technical advice for industry insiders.

The card punching machine is the most important link in the smart card production chain, and its technological evolution has always been adapted to the development of the industry. Equipment manufacturers need to pay attention to the needs of customers at all times and use new technologies to make their products more competitive. Companies using die-cutting machines need to understand the working principle of die-cutting machines and the new trends in the industry so as to choose the right model and improve their production efficiency and product quality. As the global manufacturing industry develops toward intelligence and greening, die-cutting machine technology will have more room for innovation. This will help the smart card industry and other industries achieve high-quality development.

The first batch of die-cutting machines were manufactured with mechanical parts. The products of this stage were mostly used for early card making because of their simple operation and design. Traditional mechanical die-cutting machines use mechanical structures such as cams and connecting rods to perform paper feeding, punching and other actions. The mechanical gearbox system is the source of their power. During the production process, operators need to manually set up and pay attention to the running status at all times. However, with the increasing precision requirements of products such as smart cards, the drawbacks of mechanical die-cutting machines are becoming increasingly prominent. For example, the mechanical transmission gap is large, the feeding accuracy is unreliable, and it is easy to cause defects such as punching errors. In addition, the mechanical structure limits the running speed of the equipment, which makes it difficult to meet the efficiency requirements of large-scale production. The mould replacement time is long for different cards.

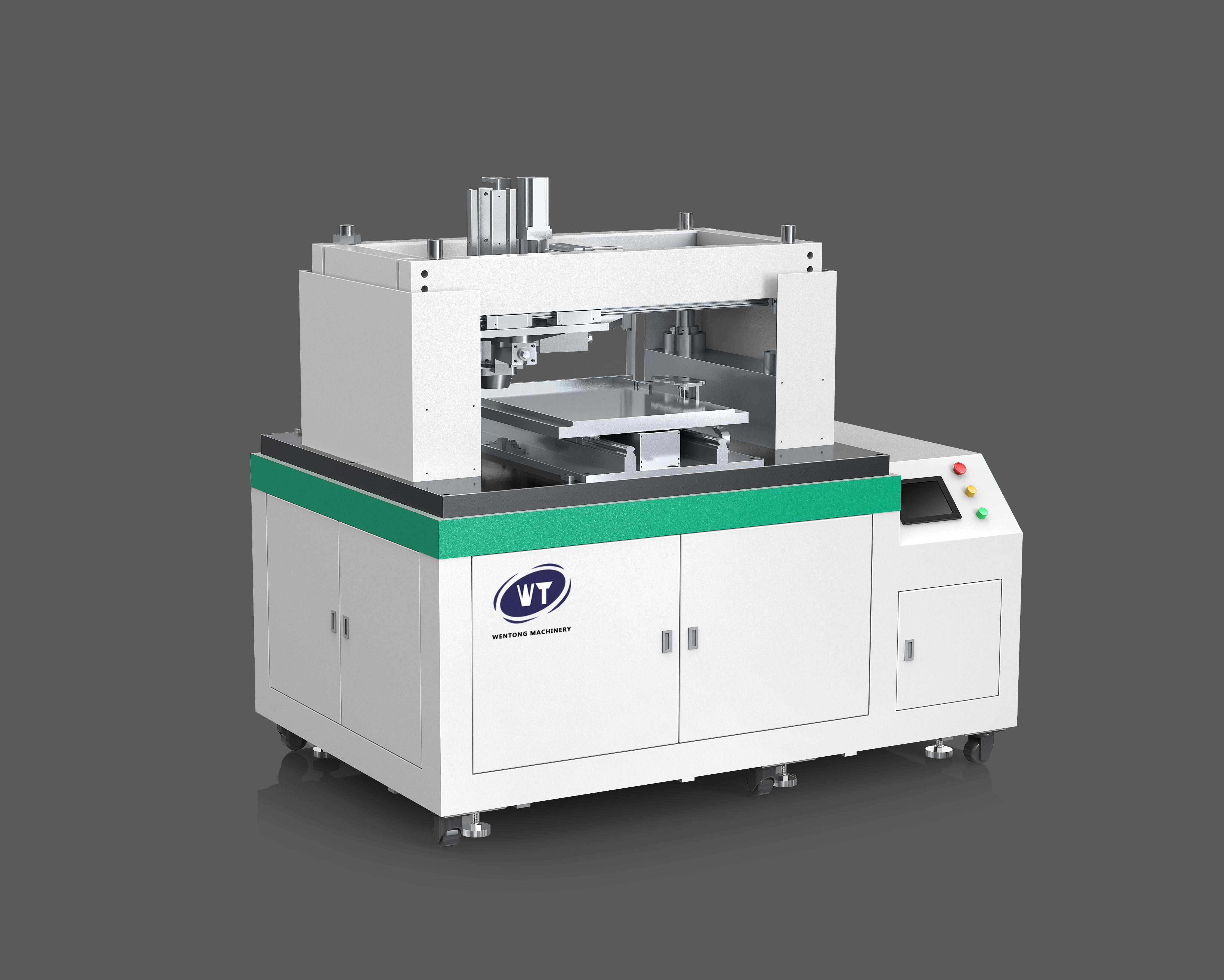

The introduction of numerical control technology has brought about revolutionary changes to the die-cutting machine, realising the transformation from "mechanical control" to "digital precision control". Modern CNC die-cutting machines mostly adopt a 7.5 kW servo system and drive important parts such as feeding and punching through a servo motor. At the same time, the high-precision grating ruler is used to find the position so that the feeding accuracy is controlled within 0.01 mm, and there is no burr in the punching process. This is exactly what smart cards need in terms of appearance and dimensional accuracy. CNC die-cutting machines are better than mechanical die-cutting machines in many ways: First, digital parameters can be set through the touch screen operation interface. For products of different materials (such as PVC and ABS smart card substrates) and different specifications, the switch can be completed by calling the preset program. This reduces the time for changing the production line. Secondly, the servo system has a stable output, the equipment running speed is increased by 30%, the mechanical wear is reduced, and the service life is longer. Some high-end models can last for more than 10 years if they are used continuously. Third, the ability of the CNC system to work with other machines allows the die-cutting machine to do many different things. It can be used to punch smart cards and game cards and can also be changed according to different needs, such as cutting books.

It is worth noting that the technical upgrade of CNC die-cutting machines has also driven the integration and innovation of supporting processes. Some CNC die-cutting machines can be combined with hot stamping technology to hot stamp patterns and text while die-cutting. This reduces the production process and increases the value of the finished product. One of the main advantages of using CNC technology in die-cutting machines is that it can integrate different processes.

With the popularisation of the concept of Industry 4.0, the combination of Internet of Things technology and die-cutting machines has become an important field of technological innovation in the industry. Its main value lies in the fact that it realises the real-time visibility and intelligent management of the production process and solves the problems of "difficult to perceive the state, difficult to predict the failure, and difficult to improve the efficiency" in traditional production. For die-cutting machine companies with a lot of business overseas, the use of IoT technology can help them better meet the needs of overseas customers for large-scale production control.

The three-layer architecture of "perception layer-transmission layer-application layer" is the basis for the die-cutting machine to realise the Internet of Things. The equipment perception layer has a variety of sensors, such as temperature, vibration, and pressure, and collects important operating parameters, such as stamping pressure, feed speed, motor temperature, and mould wear in real time. The transmission layer uses 5G, Wi-Fi, industrial Ethernet and other methods to send data to the cloud platform, ensuring real-time and stable data transmission and ensuring that it can be used in different countries and regions. The application layer of the cloud platform analyses and processes the collected data to generate the status of the equipment: running status, production capacity statistics, fault early warning, etc., and users can view it in real time with the terminal.

The significance of the networked monitoring system for smart card manufacturing lies in the fact that it has achieved full-process control. For example, if the punching pressure of the card punching machine is abnormal, the system will give an early warning to remind the operator to check the mould or the quality of the substrate to avoid a batch of unqualified products. By checking the feeding speed and stamping frequency, the system can also automatically calculate the production capacity and optimise the production plan according to the order progress.

Networking technology and die-cutting machines can also be linked to downstream processes. For example, when making smart cards, the IoT system can send the finished product information to the automatic sorting equipment after the die-cutting machine has completed the punching. In this way, the finished products can be collected in order or by category according to the pre-set rules, which avoids the errors caused by manual sorting and makes the whole production process more automated. This kind of intelligent collaboration throughout the entire process is a major sign of modern die-cutting technology adapting to the trend of intelligent production.

With people around the world paying more and more attention to the environment, the manufacturing industry has had to turn to "green production". Die-cutting machines consume a lot of electricity, so customers need to consider their power consumption and environmental performance when choosing models. This is especially true in regions with strict environmental regulations, such as the EU and North America. The main competitive advantage of die-cutting machines is that they consume less energy and produce less pollution. In order to adapt to this trend, die-cutting machines are mainly improved from two aspects: "energy consumption optimisation" and "environmental protection adaptation". This allows technical upgrades and environmental protection requirements to go hand in hand.

The main breakthrough in the utilisation of energy is the improvement of the power system and the application of intelligent energy-saving control technology. For example, the mainstream 7.5 kW servo system saves 20% to 30% more electricity than the old asynchronous motor. Servo systems also have precise speed control, automatically reducing power output when the equipment is running at no load or low speed. This further reduces energy waste. Some high-end die-cutting machines also have energy-saving hydraulic systems, as well as devices that use the heat from the hydraulic system to heat the workshop or preheat the equipment. This is an example of energy cascade utilisation.

The cutting machine not only controls energy consumption but also has environmental protection functions such as adapting to different materials and removing waste. Some scraps will be produced during the smart card production process. Manual cleaning with traditional equipment is not only time-consuming but also easily causes dust to fly. Modern die-cutting machines have automatic waste removal systems that use negative pressure adsorption to collect waste into special containers. The system can also classify and recycle waste materials so as to better utilise resources. In terms of material adaptability, when making smart cards with environmentally friendly substrates (such as degradable PVC and bio-based materials), the die-cutting machine ensures the accuracy and stability of the die-cutting process by optimising the tool material and punching parameters. This prevents the material from being damaged by the punching or from generating more waste due to its characteristics.

For die-cutting machine enterprises in Shenzhen, China, the key to going global is to meet the environmental standards of other countries. At present, the die-cutting machine products of well-known enterprises have obtained international certifications such as CE and UL. Its energy consumption also meets the EU ERP directive and the US Energy Star standard. The integrated customised overall solution can also optimise the environmental protection settings of the equipment according to the environmental protection rules and production needs of customers in different countries. This makes the product more suitable for the market.

The technical evolution of cutting machines has gone from mechanical to numerical control and then to intelligent and green. The emergence of each new technology is driven by the needs of the industry and in turn helps the downstream industries, such as smart cards, to improve. Its core value is not only reflected in the improvement of production efficiency and product accuracy but also in how to solve the pain points of the industry with technology: the unique stamping process gives smart cards and other products a unique texture, which meets the high requirements of consumers for product appearance. The design is durable and the technology is mature. The system reduces the cost of equipment maintenance for enterprises. It offers a wide range of applications and customised solutions to meet the production needs of customers in various industries and of various sizes. The use of automation and intelligent technology also helps companies save money, improve work efficiency and manage operations more effectively.

In the future, die-cutting machines will become more intelligent in three main aspects. The introduction of AI visual inspection technology will enable real-time detection of stamping quality and automatic change of stamping parameters. This will completely solve the problems of slow speed and large errors in manual quality inspection. Second, modular design will become the norm. The use of standardised modules will make it easier to quickly upgrade and customise equipment functions, shorten delivery times, and make maintenance more convenient. Third, the trend of cross-border integration will be more obvious. Die-cutting machines will be combined with other technologies such as 3D printing and laser processing to complete the production of products such as smart cards at one time. For example, chip packaging or printing of QR codes will be done simultaneously with stamping, which will make the production process more seamless.

The card punching machine is the most important link in the smart card production chain, and its technological evolution has always been adapted to the development of the industry. Equipment manufacturing enterprises need to pay attention to the needs of customers at all times and use new technologies to make their products more competitive. Companies using die-cutting machines need to understand the working principle of die-cutting machines and the new trends in the industry so as to choose the right model and improve their production efficiency and product quality. As the global manufacturing industry develops toward intelligence and greening, die-cutting machine technology will have more room for innovation. This will help the smart card industry and other industries achieve high-quality development.