Die-cutting machine is an important equipment for post-press processing. It is widely used in the production of cards, smart cards, game cards, poker cards, animation cards, bank cards, etc. Its main functions are accurate paper feeding, automatic paper collection, and automatic waste removal, which directly affect the quality and production speed of finished products. With the continuous improvement of technologies such as the Internet of Things and radio frequency identification, the smart card industry is developing rapidly in the direction of embedded, ultra-thin, and the Internet of Things. This change has put forward new upgrade requirements for the technical performance of die-cutting machines. This article will discuss the upgrade drive of future smart card technology development on die-cutting machines from four perspectives: technical foresight, accuracy requirements, data fusion, and investment allocation. At the same time, it will also be analyzed from two aspects: industry trends and equipment technology characteristics. Provide available professional knowledge for customers in the printing industry.

Embedded antenna cards have become one of the main growth areas in the smart card industry due to their extensive applications in mobile payment and identity authentication. The production of these cards requires the combination of multiple steps such as antenna implantation, chip packaging, and die cutting. The traditional segmented processing mode has problems such as process connection, accumulation of precision errors, and low production efficiency. Therefore, the integrated die-cutting technology has become the most important direction of the industry development.

From the perspective of technical implementation path, the integrated die-cutting of embedded antenna cards needs to solve two major problems: one is the stability of multi-process integration, and the other is the synchronous molding accuracy of the antenna and the card substrate. Die-cutting machines need to be better at process integration, combining die-cutting, creasing, and bonding into one. Based on this, die-cutting machines with customized overall solutions can better meet these needs. The processing steps and die parameters can also be changed to accommodate the design of embedded antenna cards.

In actual production, the use of lightweight wooden molds has become an important way to improve the efficiency of integrated processing. Traditional metal mold change usually takes 15 to 20 minutes. The wooden light mold only needs 2 to 3 minutes to change the mold. This greatly reduces the changeover time between different types of cards, which is especially useful for the printing industry with multiple batches and small batches. The hot stamping process can be directly integrated with the die-cutting machine. This means that the card can be die-cut and hot-stamped at the same time. This ensures the functional integrity of the embedded antenna card, and makes the product look and feel better.

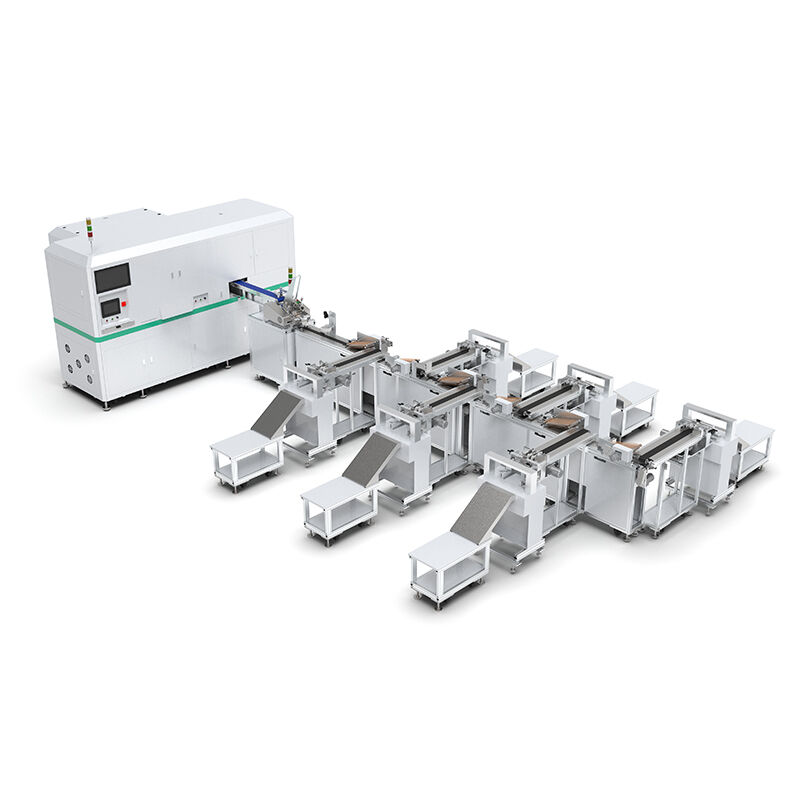

From the perspective of industry trends, the integrated die-cutting technology of embedded antenna cards will develop toward more precision and automation in the future. The die-cutting machine adopts 7.5KW automatic servo system, which can carry out precise power control, and the error control is within ±0.01mm. This helps prevent damage to the antenna. In addition, the integrated customized solution can also add the function of automatic waste removal according to customer needs. This will automate the entire process from handling raw materials to outputting finished products, which will greatly improve production efficiency.

The use of smart cards has been growing. The ultra-thin card (less than 0.3mm) has strong portability and can be applied to a variety of different occasions. The demand for ultra-thin cards is growing in the fields of wearable devices and thin electronic terminals. However, the production of ultra-thin cards requires very high precision of the die-cutting machine. Traditional die-cutting machines can hardly meet the processing requirements, and most of them have problems such as material deformation, burrs on the cutting edge, and dimensional deviation. In terms of material processing, the base material of ultra-thin cards (such as PVC, PET, etc.) with a thickness of less than 0.3mm is relatively soft, and it is easy to deform due to factors such as pressure and temperature during punching. Therefore, the die-cutting machine needs to be able to control the pressure well. The pressure is changed linearly, and the best pressure setting is set for different materials to keep the materials from being deformed. At the same time, accurate punching and no burrs are the most important quality standards for die-cutting ultra-thin cards. This requires that the knives and dies used by the die-cutting machine must be very precise, and the die-cutting equipment must be processed and assembled thru precise mechanical processing and assembly processes to make smooth, burr-free cutting edges to meet the quality standards of ultra-thin cards.

To make ultra-thin cards, the die-cutting process requires a full-process precision control system. The accurate feeding function of the die-cutting machine can ensure that the substrate does not shift and avoid dimensional deviation caused by feeding errors. The customized collection method (in order or by category) can also prevent the finished product from deforming during the collection process and ensure the consistent size of the ultra-thin card. The die-cutting precision of the ultra-thin card is up to ±0.005mm, which is very suitable for making ultra-thin cards.

The industry technical standards stipulate that the size error of die-cut ultra-thin cards should be controlled within ±0.02mm, and the deviation of the verticality of the cutting edge should not be greater than 0.01mm. With a perfect precision compensation system, the error data is monitored in real time during the die cutting process, and the equipment settings are automatically changed. High-precision die cutting of ultra-thin cards is achieved by optimizing the tool material and carefully controlling the mold gap. This is because it can be precisely punched without leaving burrs. According to industry data, high-precision die-cutting equipment can increase the yield of ultra-thin cards to more than 99.5%, which is much higher than the 85% yield of traditional equipment.

With the increasing demand for ultra-thin cards, die-cutting machines will be more precise in the future. The goal is to precisely control the accuracy within ±0.005mm. The adaptability of materials is also very important, and it can handle the processing needs of ultra-thin substrates of different materials and different thicknesses.

The rise of IoT technology has promoted the development of smart cards in the direction of IoT. The IoT card not only needs to be able to identify the identity, but also needs to be able to collect, send, and interact data. This means that the die-cutting process needs to use IoT technology to integrate data, making the production process easier to digitally control. The main idea behind data fusion is to ensure that the die-cutting machine, the production process and the smart card application requirements are perfectly combined. This will improve the production process thru a data-driven approach.

From the perspective of data acquisition, the die-cutting machine needs to have a full perception system, which can collect important information in the die-cutting process in real time, such as die-cutting pressure, feeding speed, mold temperature, finished product size error, etc. The die-cutting machine has an automatic 7.5KW servo system, which can feed back the running data in real time thru the sensor of the servo motor. This provides basic data support for data fusion. The automatic sorting function can also collect the quality data of finished products at the same time, and send the information of unqualified products to the system in real time, which is convenient for the later process improvement.

The die-cutting machine can send the collected data to the cloud platform thru the industrial Internet protocol. It can also be combined with the analysis of the production demand data of the Internet of Things smart cards. For example, according to the demand data such as the smart card chip model and antenna layout, the mold parameters and feed speed of the die-cutting machine are optimized to achieve personalized production. Data fusion can also achieve remote monitoring and diagnosis of the die-cutting process. Thru the equipment operation data, it can predict when the equipment will fail, reduce downtime, and better utilize the equipment. The die-cutting production line with data fusion can achieve an equipment utilization rate of over 92% and increase production efficiency by 15% to 20%.

From the perspective of application value, the data fusion of IoT smart card and die-cutting process can make the whole production process traceable. The data is bound to the unique ID of the smart card, and the processing information of each smart card can be traced, such as processing time, equipment settings, operators, etc. This helps to improve the quality control level of products. Integration can also improve production planning, change the die-cutting production batch and output according to market demand data, and reduce inventory backlog. Customers in the printing industry can use data fusion to improve their core competitiveness and better manage production.

In the next five years, the investment in die-cutting machines should focus on four aspects: high precision, automation, intelligence and multi-application, so as to provide services for customers in the printing industry. This is because of the development of smart card technology and the need to upgrade die-cutting machines. With reasonable configuration, the equipment can be more adaptable and competitive. Here are some specific recommendations for three aspects: selecting the most important technical configurations, picking the most important core functions, and focusing on return on investment.

In the priority order of technical configuration, the high-precision core components should be placed first. Including 7.5KW automatic servo system, precision mold and cutter, high-precision sensing system, etc. These are all necessary for making high-end smart cards, such as embedded antenna cards and ultra-thin cards. The automation function should be set better. In order to improve production efficiency and reduce labor costs, functions such as automatic feeding, automatic waste removal, automatic classification and sorting, and customized finished product collection should be combined. Data shows that after the automation level of the die-cutting production line is improved, the labor cost can be reduced by 30% to 40%. Integration, gradually establish intelligent control system, and the Internet of Things smart card production linkage, so that the equipment is more intelligent.

For the core function, the printing industry should give priority to the die-cutting equipment with multiple functions. This allows one machine to complete multiple jobs, such as the punching and cutting of smart cards, books, filter paper, etc., making the equipment more practical. It is selected as standard configuration. Its 2-3 minute quick mold change capability can greatly improve the switching efficiency of the production line and meet the production needs of small batches and multiple varieties. The integrated customized overall solution can change the function and processing steps of the equipment, meet the specific production needs of each customer, and make the equipment more flexible. The hot stamping technology can make the appearance of high-end smart cards more beautiful, and the products can play a role in more occasions.

According to industry forecasts, the global smart card market will grow at a compound annual growth rate of 8.5% from 2025 to 2030. This will drive the demand for high-end die-cutting machines. Printing industry customers can enter the high-end smart card processing market and realize product value-added by purchasing high-precision, automated and multi-functional die-cutting machines. Calculations show that the investment recovery period of die-cutting equipment with core upgrade configuration is about 1.5-2 years. This is much shorter than the three to four years required by traditional equipment. The durability of the equipment also helps it to run smoothly for a long time, reduce maintenance costs, and further improve the return on investment.

The future growth of smart card technologies such as embedded, ultra-thin, and the Internet of Things will drive the die-cutting machine to fully upgrade to high precision, automation, intelligence, and multi-application. It can achieve the precision control of ±0.005mm, realize the unmanned fully automatic production, and realize the data combination and multi-category processing, so as to meet the production needs of high-end smart cards.

The following core conclusions can be drawn from the data combined with the development trend of technology: First, in terms of market demand, the demand for high-end die-cutting machines worldwide will grow at a compound annual growth rate of 11.5% from 2025 to 2030, of which the proportion of high-precision die-cutting machines suitable for smart card processing will exceed 60%; Second, from the perspective of technical value, the equipment using 7.5KW servo system, wooden lightweight mold and integrated customized solution can improve the production efficiency of smart cards by 20%-30%, the yield rate can reach more than 99.5%, and the labor cost can be reduced by 30%-40%; Third, from the perspective of investment return, the investment recovery period of high-end die-cutting machines is about 1.5-2 years, and the investment value is good.

Printing industry customers should take advantage of the growth in smart card technology. The focus should be on selecting high-precision, automated, multi-purpose die-cutting machines. It is also necessary to improve production capacity and product quality thru the configuration of intelligent technology. It is also necessary to pay attention to how the die-cutting process is combined with the Internet of Things technology to improve the level of production management and make the core business more competitive. Die-cutting equipment manufacturers in Shenzhen, China, have great potential in the global market because they have mature technology and can manufacture products that meet the needs very well. The die-cutting machines they produce are unique in texture, durable and versatile, and can meet the needs of global smart card processing enterprises.