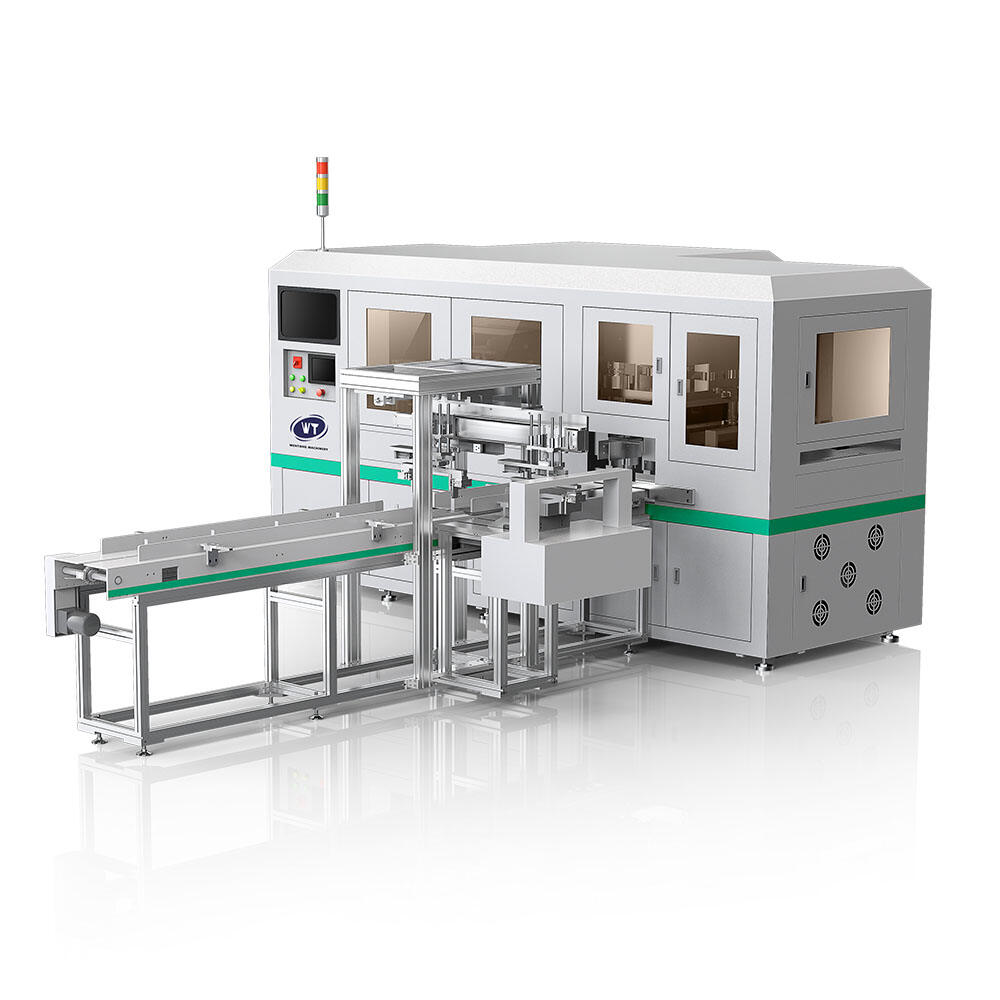

In the highly competitive global card manufacturing market, simply owning a cutting machine is not enough to stand out from the competition. The main problems faced by manufacturers are becoming more and more difficult: how to measure and evaluate the accuracy to make the card feel better? How to use specific data to plan flexible production? How to transform the efficiency improvement after the process into a clear return on investment? This article will introduce in detail the main technical features and functions of the professional-grade animation card die-cutting machine. It will also show through specific data how it systematically responds to these challenges and provides a measurable and predictable complete production closed loop for global manufacturers.

1. High-precision punching system: the key to measuring texture and precision

The quality of the module directly affects the quality of the finished product. To achieve this, there must be a precise system that can measure and rate:

-

Mechanical platform and precision parameters: The frame is cast with HT250 or above cast iron or welded with Q235B steel plate. After secondary ageing treatment, the deformation under long-term load is guaranteed to be no more than 0.05 mm/m. The core moving parts adopt a pre-tightened precision linear guide rail and high-rigidity ball screw to ensure the repeated positioning accuracy within ±0.1 mm. This is the geometric basis for burr-free cutting.

-

Intelligent pressure control parameters: The system has a built-in high-resolution pressure sensor and a closed-loop servo pressure control system. The pressure adjustment range is usually 20~600 KN, and the best value can be adjusted according to the characteristics of the material. For example, when punching 0.76 mm PVC card material, the pressure can be set to 380 KN ± 5 KN. When stamping 350g high-grade coated paper, the pressure can be quickly switched to 85KN±2KN. This fundamentally eliminates the burrs or indentations caused by improper pressure.

-

Efficiency parameters: The standard punching speed of the equipment is 30-80 times/minute, and the specific speed depends on the complexity of the mould and the material. With the efficient waste removal device, the effective operation rate can reach more than 95%.

2. Automatic sorting and distribution system of cartoon card die-cutting machine

This feature connects the production data stream directly to management decisions. Its effectiveness can be measured by:

-

Identification system parameters: Optional visual identification system based on an industrial CCD camera with more than 2 million pixels and identification accuracy up to 0.1 mm/pixel, or an RFID card reader supporting ISO 14443 A/B protocol. The system can identify the card surface pattern, printed marks or built-in chip in milliseconds, and the identification accuracy rate is not less than 99.9%.

-

Sorting execution parameters: The sorting mechanism is driven by a servo motor or a high-speed solenoid valve, and the response time of the sorting action is less than 0.1 seconds. The standard configuration can sort 2-6 categories in real time. Customers can also request more sorting channels. The success rate of sorting is no less than 99.5%.

-

Customer value conversion: This module can directly replace 3-5 full-time sorting workers. If labour costs are saved, the cost can usually be recovered in 12-18 months based on three shifts.

3. Flexible manufacturing capabilities: the economic factors that influence how much a machine can do

The flexibility of the device is reflected in its ability to transform and adapt:

-

Quick mould change system: adopts European brand hydraulic mould locking system or mechanical quick positioning fixture. The intelligent positioning pin can shorten the mould change time to 5-10 minutes (from shutdown to the production of the first qualified product). The control system can save more than 100 sets of production parameter recipes for different products.

-

Material adaptability parameters: Standard equipment can handle materials with a thickness between 0.15 mm and 2.0 mm, and the maximum feed size is usually 650 mm x 950 mm (but can be changed). It works perfectly with roll or sheet material of paper, PVC, PETG, ABS and composites.

4. Customised collection and stacking system: the bridge parameters connecting the process

The regularity of finished product collection directly affects the smooth progress of the next automatic packaging process.

-

Collection accuracy parameters: Whether it is sequential collection or classified collection, the stacking neatness error can be kept within ±0.5mm. You can set the height of a single stack to meet your needs. The most common range is 50 to 150 mm. It also has a height sensor that sends a signal to automatically change the stack.

-

Output interface parameters: The acquisition unit has standard electrical interfaces (such as 24V I/O and Ethernet TCP/IP) and mechanical interfaces. It can be directly connected with an automatic strapping machine, a robot packing unit or an AGV trolley to ensure smooth operation of the assembly line.

5. Integrated hot stamping function module: process fusion parameters are formed at one time.

As a key process option, the standards for its integration and accuracy are clear.

-

Synchronisation accuracy parameters: The hot stamping unit and the die-cutting unit adopt the same motion controller to synchronise the electronic cam. Even at the fastest production speeds, the hot stamping pattern and die-cut outline always remain within ±0.15 mm of each other.

-

Hot stamping parameters: hot stamping temperature range 0-300℃±1℃, pressure range 0-20 MPa. Suitable for domestic and imported electrochemical aluminium foil, meeting the needs of flashcards and anti-counterfeiting labels in different fields.

II. Systematic technical advantages and overall solution settings

The reason why the above functional modules can work so well is that there is a mature and stable technical platform at the bottom of the device. These platform parameters are the values that customers can rely on for a long time:

-

The main components of the drive control system are: the main drive of the whole machine adopts a 7.5 kW (or 11 kW) AC servo motor. Speed accuracy error under rated torque ≤ ±0.1%. The 32-bit multi-axis motion control card is adopted, and the pulse output frequency is up to 4 MHz. The synchronicity of all action instructions is guaranteed, and the response time is at the millisecond level. The machine runs under rated load, and the noise is usually less than 75 decibels. It meets the environmental protection requirements of international certifications such as CE.

-

Structural design and durability guarantee parameters: The static deformation of the main frame is optimised by finite element analysis (FEA) to ensure that the deformation of the worktable is no more than 0.08 mm under the full load pressure of 600 KN. The design life of key bearings, guide rails, seals and other components is more than 60,000 hours. The international top brands such as SKF, THK and Parker are adopted. The target for the mean time between failures (MTBF) is at least 4,500 hours, and the target for the mean time to repair (MTTR) is at most 2 hours.

-

Customised integration solutions range: Our R&D centre in Shenzhen can be fully customised according to customer requirements. Customisation can include, but is not limited to:

-

Customised size: the maximum processing area can reach 1300 mm x 1850 mm (customisable).

-

Automatic connection: Provide a JDF/JMF format data interface for mainstream printing machines such as Heidelberg, Komori, and KBA to realise intelligent production scheduling.

-

Electrical standard: It can be applied to the common industrial voltages of 380V/50Hz, 460V/60Hz, 220V/60Hz, etc. The protection level can reach IP54.

-

Safety standards: Dual-circuit safety light curtain, emergency stop button and safety door lock conforming to CE/UL standards.

Conclusion

For serious manufacturers who want to sell their products globally, the selection of cartoon card die-cutting machines has shifted from qualitative evaluation to quantitative decision-making. The key parameters discussed in this article, such as ±0.1 mm repeated positioning accuracy, ≥99.9% sorting accuracy, 5–10 minutes of rapid mould change, and 600 kN stable pressure, jointly create a predictable, high-efficiency, and low-operating-cost production system.

The equipment not only improves production capacity but also makes many verified performance commitments. For example, it ensures that each card has the same high quality by using precise burr-free stamping parameters. It also ensures error-free work and frees the workers of the next process through the efficiency parameters of automatic classification and sorting. Finally, through the flexible parameters of integrated customised overall solutions, it ensures that your investment can accurately meet current needs and calmly cope with future changes.

Based in Shenzhen, we combine the world's best precision manufacturing standards with a deep understanding of card technology. We promise to give you not only equipment but also a clear and reliable technical contract and a long-term value growth partnership.