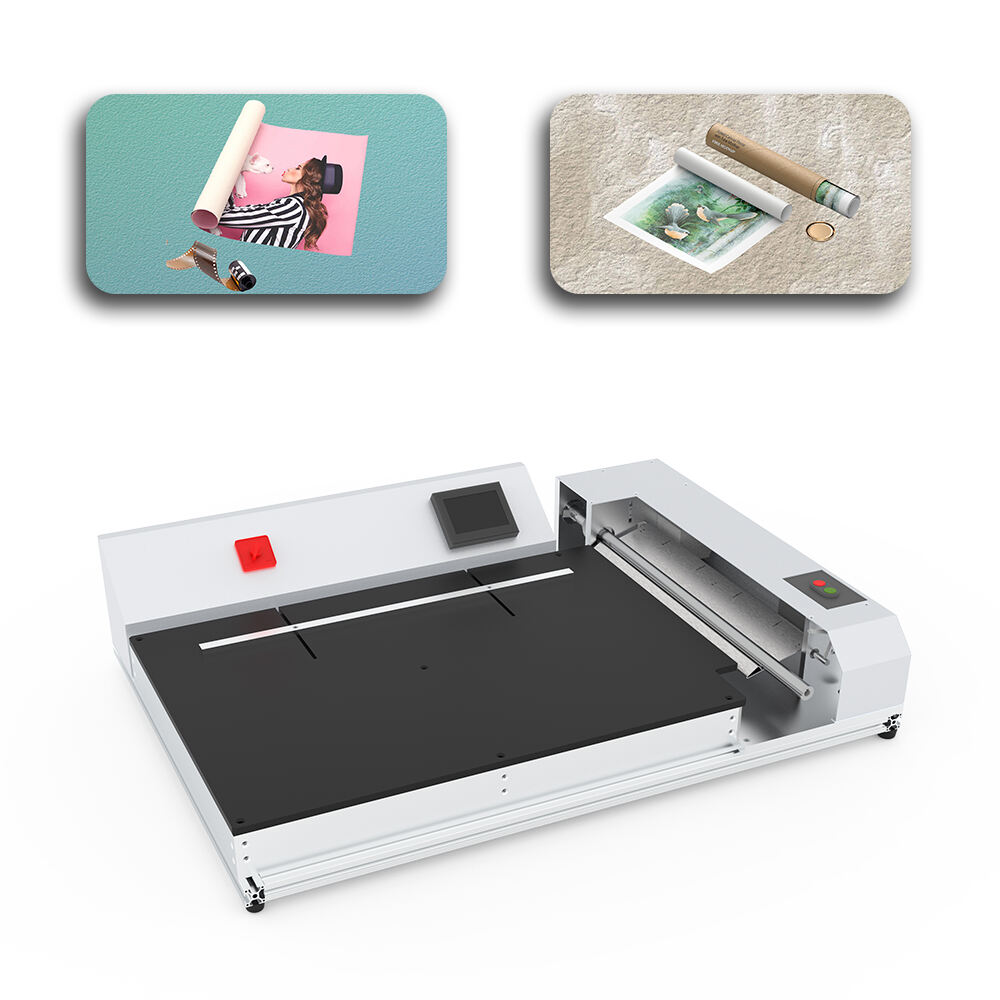

بالنسبة للمنتجات مثل الملصقات والبطاقات التعليمية وEVA، فإن ماكينة لف ورق البطاقات التعليمية هي المعدات الميكانيكية الرئيسية. إن استقرار ماكينة لف ورق البطاقات التعليمية يحدد جودة المنتج وكفاءة الإنتاج. توفر ماكينة اللف حلاً لمشكلة اللف اليدوي، حيث يكون اللف اليدوي غير فعال، مكلفًا، وغير دقيق، مما يؤدي إلى منتجات مجعدة وغير جذابة من الناحية الجمالية. تتميز ماكينة اللف الاحترافية للبطاقات التعليمية بدرجة عالية من الأتمتة والتحكم الدقيق، وهي الحل الأمثل لمشكلة اللف اليدوي. تسجل هذه المقالة الاحتياطات الخاصة بماكينة لف ورق البطاقات التعليمية وتقدم إرشادات تشغيل احترافية للعملاء في الخارج. بناءً على فهمي لتصنيع ماكينة لف الورق، تُباع منتجاتها في جميع أنحاء العالم.

قابلية التكيف في النظام ماكينة لف ورق البطاقات التعليمية هي قوتها. وتشمل هذه المرونة مجموعة واسعة من الركائز، مثل أوراق الطباعة والتغليف، والبلاستيك، والهياكل المركبة. ومع ذلك، يمكن أن تختلف الخصائص الفيزيائية لهذه المواد بشكل كبير. إن التحضير الجيد، مثل فترة التأقلم والتحقق من المعدات قبل التشغيل، سيساعد على تجنب الأعطال.

تعتمد ملاءمة المادة على مرونة نوع الركيزة ومعايير المعدات. بالنسبة للمواد الورقية، وبخاصة الورق المستخدم في الطباعة والتغليف، فإن العامل الرئيسي الذي يجب أخذه بعين الاعتبار هو وزن الورق. بالنسبة للورق المستخدم عادةً في بطاقات التعلم والذي يتراوح وزنه بين 80 و120 غرامًا، ينبغي ضبط شد اللف على نطاق متوسط تجنبًا لتمزق الورق بسبب الشد الزائد. أما بالنسبة للأفلام البلاستيكية والمواد المركبة ذات الأسطح الناعمة والقابلية العالية للتشكل، فيجب تركيب أجهزة مضادة للانزلاق على المعدات، ويجب تنظيف البقع الزيتية والشوائب من على السطح تجنبًا لحدوث عدم انتظام وزيادة شد اللف أثناء عملية اللف. بالإضافة إلى ذلك، إذا استلزم الأمر لفّ أكثر من مادة في الوقت نفسه، فيجب التحكم في انحراف العرض والسماكة للمواد ضمن مدى ±0.5 مم، حتى تتمكن المعدات من تحقيق وظيفة اللف المتعدد للمواد.

أثناء الفحص، يجب أخذ النظامين الميكانيكي والكهربائي للتحكم في الاعتبار. من الناحية الميكانيكية، يجب التحقق من توازي بكرة اللف. إذا وُجد أي انحراف، فيجب تعديل دعامة عمود البكرة لتقليل فرق إجهاد اللف إلى الحد الأدنى. وفي الوقت نفسه، يجب التعامل مع التآكل الميكانيكي بشكل فوري، وإضافة زيت التشحيم في الوقت المناسب إلى التروس، السلاسل، وأجزاء نقل الحركة الأخرى التي تحتاج إلى تشحيم. أما بالنسبة للنظام الكهربائي للتحكم، فيجب ضمان حساسية إعدادات شاشة اللمس، والتحقق من حالة تشغيل وحدة الأتمتة الفعالة. على سبيل المثال، يجب أن يعمل النظام بشكل طبيعي لضبط التوتر تلقائيًا، وإصدار إنذار بالانقطاع لتجنب إيقاف التشغيل الكهربائي. ويجب إدارة مشكلات توقف وحدة الأتمتة لتفادي أعطال التحكم الكهربائية أثناء التشغيل.

عملية التشغيل للمكبس ماكينة لف ورق البطاقات التعليمية يتطلب تحكمًا دقيقًا لضمان جودة المنتج. في ظل الظروف التشغيلية القياسية، يمكن الاستفادة القصوى من المزايا البسيطة والفعالة للجهاز، ويمكن تجنب الأخطاء البشرية.

عند ضبط الإعدادات، يجب اتباع مبدأ "مطابقة خصائص المادة" أولاً. على سبيل المثال، يُوصى بأن تكون سرعة جمع الورق للمواد المصقولة المستخدمة عادةً في البطاقات التعليمية منخفضة نسبيًا وتتراوح بين 8-12 م/دقيقة. فإذا كانت السرعة عالية جدًا، فقد تحدث تجاعيد بسهولة. أما بالنسبة لمادة EVA المرنة، فيُوصى بضبط شد المادة عند 5-8 نيوتن. وبفضل النظام المتقدم للمعدات، يمكن تعديل ومعاينة معلمات الشد واللف في الوقت الفعلي لتحقيق لف متجانس. وعند تغيير المنتجات ذات المواصفات المختلفة، يمكن استخدام وظيفة الذاكرة في المعدات لاستدعاء المعلمات الإعدادية المناسبة. وهذا يعكس التصميم المُريح للمعدات، ويُجنب فقدان الوقت الناتج عن التعديلات غير الضرورية. وأخيرًا، بالنسبة لللف بورقة واحدة أو متعددة، ولا سيما اللف متعدد الأوراق، يجب تفعيل التحكم التزامني التلقائي في الانحراف للحفاظ على المحاذاة الصحيحة للتراص، ويُعد فحص توزيع المادة أمرًا بالغ الأهمية لللف المتعدد الصحيح.

حتى أبسط الآلات تتطلب تدريبًا للمُشغل. أثناء التشغيل، يتم تعديل عملية فك اللفافة والأعطال مثل الحواف غير المنتظمة والتجاعيد تلقائيًا في الوقت الفعلي من خلال شاشة اللمس، دون الحاجة إلى تدخل يدوي في المعدات. تم تصميم كل مكون من مكونات النظام الآلي للسماح للمعدات بالعمل لفترات طويلة دون انقطاع، ولكن يجب على الأفراد المؤهلين التحقق من محيط النظام كل 30 دقيقة لتجنب نفاد المواد الخام أو المنتج النهائي أو حدوث عدم توازن ميكانيكي. يجب عليهم التأكد من حالة المحيط، ووضوح صوت المعدات، وهوامش المواد. وأخيرًا، ولأسباب تتعلق بالسلامة، يجب إيقاف تشغيل المعدات قبل فتح أي أبواب أمان متصلة ببعضها.

الموثوقية الشاملة والعمر الافتراضي لل ماكينة لف ورق البطاقات التعليمية تعتمد على كفاءة الصيانة المخطط لها التي تُنفذ بعد اكتمال دورة الإنتاج، ويمكن لخفض وقت توقف المعدات أن يحسن معدل الاستخدام.

يجب التخطيط للصيانة والتنظيف اليومي والصيانة الروتينية. بعد انتهاء التشغيل اليومي، يجب قطع التيار الكهربائي وتنظيف بقايا الورق والغبار والأوساخ الأخرى على سطح المعدات. وخصوصًا، يجب مسح سطح أسطوانة اللف جيدًا بقطعة قماش ناعمة لتجنب تأثير الشوائب المتبقية على دقة اللف عند الاستخدام التالي. بالنسبة لصندوق التحكم في المعدات، يجب تنظيف الغبار الداخلي بشكل دوري على الأقل مرة واحدة شهريًا لمنع حدوث دوائر كهربائية قصيرة نتيجة تراكم الغبار. كما يجب إجراء إزالة الغبار خلال الصيانة الروتينية الفصلية، إلى جانب مراجعة تحكم صندوق الغبار وفحص التآكل على أسطوانات اللف، والتي يجب أن تكون المحور الرئيسي لأنشطة الصيانة الخارجية. إذا كانت هناك خدوش على سطح الأسطوانة، فيجب تلميعها. كما يجب فحص ضغط الزيت في النظام الهيدروليكي لضمان عدم تأثر دقة التحكم في المعدات. بالإضافة إلى ذلك، يجب ضبط وحدة الأتمتة الخاصة بالمعدات لضمان التشغيل الطبيعي لوظائف التنبيه التلقائي والإيقاف التلقائي وغيرها.

لكي يتم التعامل معها بفعالية، يجب الجمع بين تشخيص الأعطال الشائعة والسمات الخاصة بالمعدات. عند تشخيص عطل عدم انتظام مادة اللف، يجب أولاً التحقق مما إذا كان مستشعر التوتر معطلاً. وإذا كان المستشعر تالفاً، فيجب استبداله. إذا انخفضت سرعة اللف فجأة، فقد يكون السبب الجذري هو تآكل نظام النقل. في هذه الحالة، يجب فحص التروس والسلاسل وتجانسها، وتقديم التزييت المناسب. تعرض لوحة تحكم المعدات رمز العطل. وباستشارة الرمز في الدليل المرفق، يمكن للمشغل تحديد العطل وبالتالي تحديد المعدات المعطوبة. يُبرز هذا التصميم بساطة تشغيل النظام، ما يسمح حتى للمشغلين المبتدئين بإصلاح الأعطال الأساسية بسرعة.

بصفتنا شركة مصنعة ووسيط توزيع عالمي لآلات الأوراق الملفوفة ومقرنا في شنتشن، الصين، فقد نما عملنا ليصبح موردًا موثوقًا به في الأسواق الخارجية. ويرجع ذلك إلى خمسة أسباب رئيسية: تعتمد المعدات على وحدات أوتوماتيكية، مما يزيد الكفاءة الإنتاجية بأكثر من 60٪، وهي نسبة أعلى بكثير من كفاءة التفاف اليدوي؛ ويمكن للنظام المتقدم للتحكم تحقيق دقة تفافية تبلغ ±0.1 مم، مما يحسن بشكل كبير جودة المنتج ومعدل العائد؛ وتتمتع المعدات بقدرة تكيف قوية، ويمكن استخدامها مع مجموعة متنوعة من المواد الأساسية مثل الملصقات والمواد التعليمية وEVA، كما تُستخدم على نطاق واسع؛ ويشكّل واجهة المستخدم البديهية تبسيطًا لعملية التدريب، حيث يمكن للموظفين الجدد البدء بسرعة؛ إضافةً إلى وجود آلية تبديل مرنة متكاملة يمكنها تحقيق التحول السلس بين وضع التفاف ورقة واحدة ووضع التفاف متعدد الأوراق لتلبية احتياجات الإنتاج المتنوعة.

التشغيل الموحّد ضروري لتعظيم أداء آلة ورق بكرات البطاقات التعليمية. ويشمل ذلك تكييف المواد قبل التشغيل، وضبط المعايير أثناء التشغيل، والصيانة بعد التشغيل. ولمساعدت العملاء في تقليل التكاليف وتحسين الكفاءة التشغيلية، نقدم دعماً فنياً شاملاً ما بعد البيع بالتزامن مع آلات بكرات الورق عالية الجودة التي نزودها عالمياً.