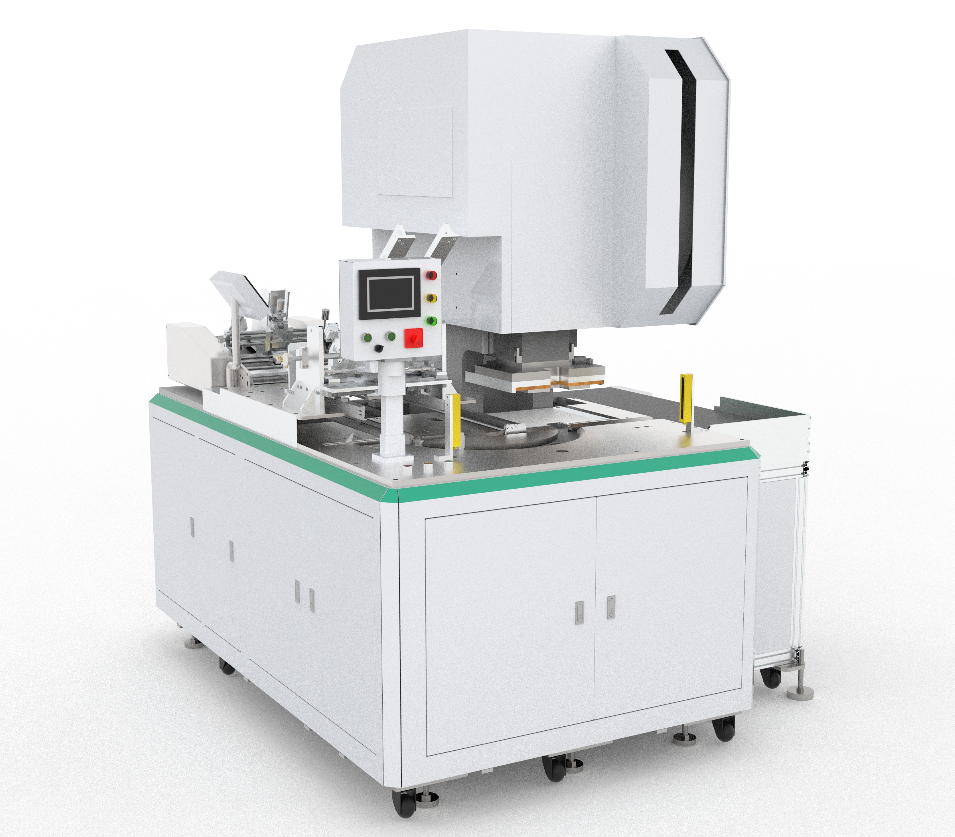

Streamlining Workflows with Automation in Book Making Machines

Integration of automation software transforms traditional publishing workflows

Today's book manufacturing equipment can cut job completion times by around 30 to 50 percent compared to older methods. This happens because they replace all those tedious manual prepress steps with smart imposition software and automatic proofing systems. The machines handle page layout adjustments automatically depending on what kind of binding will be used, keeping those critical gutter margins just right without needing anyone to fiddle with templates constantly. Production supervisors get live updates through dashboard screens showing where things might be slowing down in the process. This lets them move staff and materials around as needed before problems actually happen.

JDF-based systems enable seamless data flow across production stages

When print shops start implementing JDF protocols, they open up two-way communication channels between their bookbinding equipment and earlier stages such as digital printing operations. According to findings from the 2023 Print Industry Benchmark Study, companies that switched to JDF workflows saw a dramatic drop in errors during the transition from prepress to binding, cutting these issues down by around 78% when compared with traditional manual file transfer methods. The system takes care of file version problems too since it checks PDF/X-4 files against what the presses actually need right before trimming begins, eliminating those frustrating version mismatches that used to plague production runs.

Reduced bottlenecks and downtime through integrated book making machine workflows

Automated machine-to-machine synchronization ensures perfect timing between perfecting presses and inline binding units. When one process slows, upstream devices automatically throttle output through closed-loop feedback systems. This integration reduces substrate jams by 63% in saddle-stitched booklets (Printing Industries Alliance 2024) while maintaining 99.2% uptime during six-hour production runs.

Smart Technologies Enhancing Precision and Safety in Book Finishing

Modern book making machines now leverage artificial intelligence (AI) to refine finishing processes while prioritizing workplace safety. These innovations address key pain points in book production, from costly setup errors to inconsistent binding quality.

AI-Driven Imposition and Error Detection Minimize Setup Mistakes and Misruns

Artificial intelligence looks at what needs to be printed and checks past production records to figure out the best way to arrange sheets for printing. These smart systems catch problems early on, like when there are wrong numbers of pages or folds that don't match up, which cuts down on wasted prints by around 45% according to industry reports from 2024. When things get to the finishing stage, the AI keeps watching closely and will flag issues such as crooked book spines or pages that aren't trimmed evenly. This heads off all sorts of waste further along in the process where fixing mistakes becomes much more expensive and time consuming.

Smart Finishing Systems Ensure Consistent, High-Precision Binding Results

Modern equipment now uses laser guidance along with closed loop calibration systems to keep things within about half a millimeter accuracy during both glue application and when attaching covers. The temperature control features built into most adhesive systems today help ensure strong bonds regardless of whether we're dealing with thin or thick papers, or working under varying shop conditions. According to actual shop floor reports, companies implementing these kinds of tech improvements typically see around a 38 percent drop in binding problems. What's really impressive is that they manage to hit close to 99.3 percent success rate on the first try even when running multiple product types through the same line.

Reduced Manual Labor Improves Workplace Safety and Output Reliability

The automated systems for jogging and stacking books have really cut down on all those backbreaking lifting jobs that used to be part of regular book finishing operations. When workers get too close to any moving components, built-in safety features kick in and shut off the machines instantly. According to recent industry data from the 2024 Print Industry Safety Report, shops that switched to these intelligent book production units are seeing around 30 percent fewer accidents happening on site, plus about 22 percent drop in workers' compensation cases compared to older methods. These numbers show just how much difference modern technology can make in keeping employees safe while they work.

Maximizing Uptime and Accuracy Through Machine-Software Synergy

Today's book manufacturing machines have reached new levels of reliability thanks to how closely mechanical parts work with control software. When companies adopt JDF workflows, they create seamless connections between all stages from design to final binding. Industry standards show these systems stay operational around 97.4% of the time, which is pretty impressive considering what goes on behind the scenes. The way hardware and software now talk to each other means settings automatically sync between different machines. This eliminates the need for workers to constantly input the same data manually, something that used to cause about a quarter of all production holdups according to Printing Industries of America stats from last year.

Machine-Software Integration Boosts Efficiency and Minimizes Downtime

Modern binding machines can automatically tweak their settings when moving from regular paperbacks to hardcovers or special format books. These systems come with built-in preset configurations that work hand in hand with smart software to handle everything from quick turnaround academic publications to limited edition art books, all without needing someone to manually adjust things. The result? Changeover times drop around two thirds compared to what they used to be with old fashioned manual methods. And despite all this speed, the bindings still stay accurate within just under half a millimeter tolerance, which is pretty impressive for anyone who cares about book quality.

Automated Bookbinding Adapts Quickly to Variable Print Job Requirements

Research published in Scientific Reports back in 2023 shows that when machines work together with software systems, they cut down on mistakes made by humans during book manufacturing. The error reduction ranges between 58 to 62 percent across seventeen different factors they measured. These automated quality checks basically do full circle inspections as books get trimmed and pages are put together. They catch problems with how signatures line up before bad products move further along the production line. For companies using this kind of feedback loop system, there's been a noticeable drop in wasted materials around 34 percent according to industry reports. And most impressive? Their initial success rate now tops 99.1 percent for finished products right off the assembly line.

Reduction in Manual Intervention Cuts Error Rates by Up to 60%

By shifting repetitive tasks like page counting and glue application to robotic systems, facilities report 73% fewer workplace injuries related to manual book assembly. Error-prone tasks such as foil stamping alignment now rely on laser-guided positioning systems that achieve 0.05mm repeatability precision unattainable through human operation alone.

Enabling Scalable and Cost-Efficient Short-Run Book Production

Book Making Machines Support Scalable On-Demand Production for Dynamic Markets

The latest generation of book printing equipment is changing how publishers think about costs, since now they can produce runs starting at just 50 copies without losing money on each unit. According to recent research from PrintForecast in 2023, those who switch to these automated short run systems finish their print jobs around 40 percent quicker than what was possible with old school offset printing techniques. What does this mean practically? Publishers gain the flexibility to match production with sudden surges in demand. Think about textbooks needed right before classes start each semester, or special edition art books that might generate unexpected buzz online but would be risky to mass produce ahead of time.

Short-Run Printing Reduces Overproduction and Inventory Storage Costs

This tech cuts down on storage costs around 35% each year because publishers no longer need to stockpile printed copies when they can produce books only when sold. The automated printing equipment matches traditional methods in price once they hit about 300 copies thanks to smart ways of using paper and saving energy during production. New digital binding machines work with books ranging from thin pamphlets to thick novels up to 400 pages without needing someone to tweak settings manually. That means older titles that weren't selling well before suddenly become worth keeping alive through these tiny print runs whenever there's demand.

Sustainability Benefits: Reducing Waste and Energy Use in Book Manufacturing

Precise Material Usage and Trimming Significantly Cut Waste in Book Production

Today's book manufacturing equipment comes equipped with smart trimming tech that cuts down on wasted paper stock anywhere from 22 to 30 percent when compared to old school hand cutting techniques according to the Sustainable Print Alliance report from last year. These machines run on sophisticated nesting software that gets around 97.4% usage out of materials by positioning all those little book parts just right down to the tiniest detail. Plus there are sensors built in that constantly tweak where blades cut so things don't get messed up during production runs. For average sized printing shops, having these waste tracking features actually saves them about 18 tons worth of scrap every single year which makes a huge difference both environmentally and financially speaking.

Higher Output Capacity with Minimized Scrap Enhances Environmental and Cost Efficiency

When bookmaking machines integrate energy recovery features along with smart scheduling systems, they manage to slash energy usage by about 27% for every thousand books produced without dropping below 95% operational time according to Green Manufacturing Review from last year. The closed loop recycling systems in place today can turn around roughly 89% of those paper scraps back into usable materials instead of sending them to landfills. This not only cuts down on raw material purchases but saves companies serious money too. Manufacturers report saving around $58k annually just on waste disposal fees alone when implementing these practices, plus they stay ahead of regulatory requirements for green manufacturing standards across different regions where they operate.

FAQ Section

What are the benefits of using automated book making machines?

Automated book making machines streamline workflows, reduce errors, improve efficiency, and enhance workplace safety, while also offering significant environmental benefits.

How do JDF-based systems improve book production?

JDF-based systems enable seamless data flow across production stages, reducing errors, improving file management, and enhancing overall process integration.

What role does AI play in modern book manufacturing?

AI-driven technologies help minimize setup mistakes, enhance precision, and detect errors early in the book production process, which improves efficiency and reduces waste.

How do these technologies impact workplace safety?

Modern book making machines with automation reduce manual labor, improve operation safety, and significantly lower workplace accident rates.

Is it cost-effective to use automated book printing for small runs?

Yes, automated systems are particularly cost-efficient for small runs, reducing overproduction and inventory storage costs, and providing flexibility to meet market demands.

How do book making machines contribute to sustainability?

They minimize waste, optimize material usage, integrate energy-saving features, and enhance recycling practices, supporting environmentally friendly manufacturing processes.

Table of Contents

- Streamlining Workflows with Automation in Book Making Machines

- Smart Technologies Enhancing Precision and Safety in Book Finishing

- Maximizing Uptime and Accuracy Through Machine-Software Synergy

- Enabling Scalable and Cost-Efficient Short-Run Book Production

- Sustainability Benefits: Reducing Waste and Energy Use in Book Manufacturing

-

FAQ Section

- What are the benefits of using automated book making machines?

- How do JDF-based systems improve book production?

- What role does AI play in modern book manufacturing?

- How do these technologies impact workplace safety?

- Is it cost-effective to use automated book printing for small runs?

- How do book making machines contribute to sustainability?