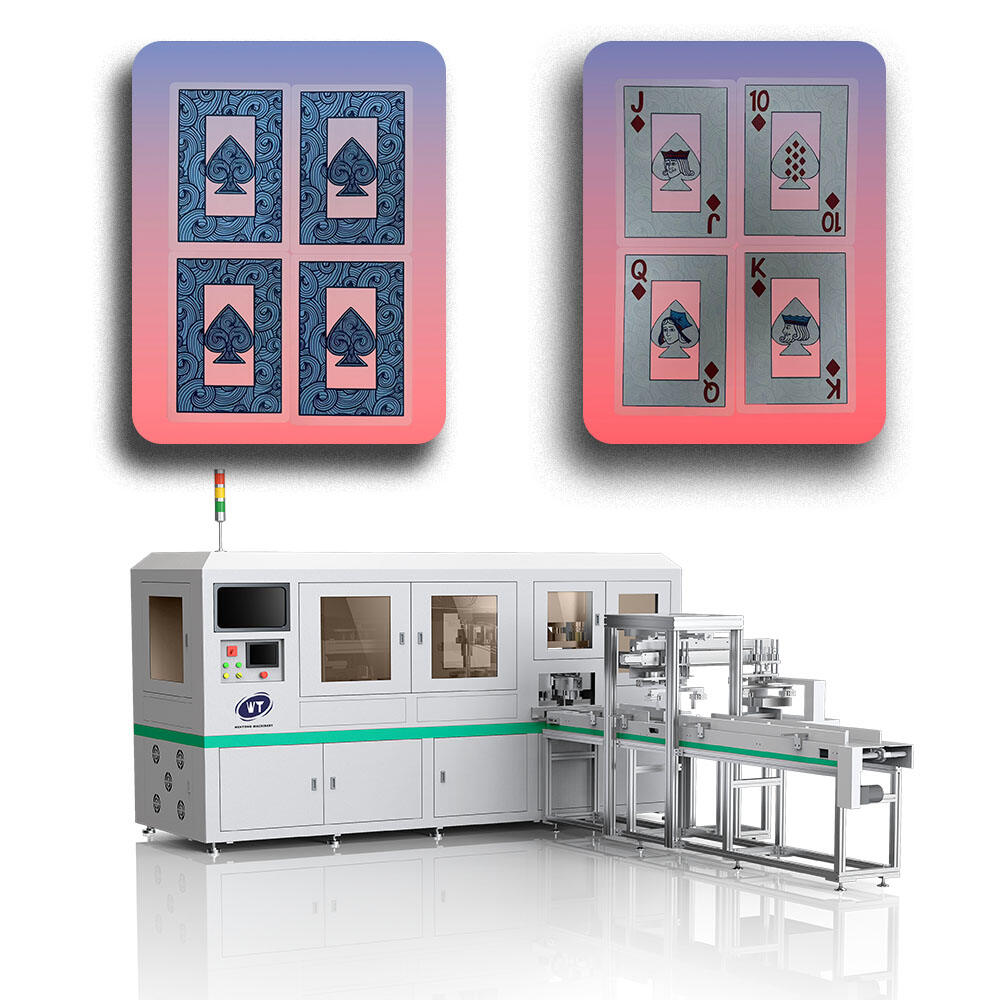

The feel of playing cards comes from the perfect combination of material properties and die-cutting technology. The transparent card die-cutting machine is designed for the physical properties of common card materials such as PVC, PET, and high-quality plastics. The targeted technical design improves the processing precision and the hand-feeling experience. It is a key piece of equipment for making cards, smart cards, business cards, game cards, animation cards, bank cards, and other products. Its ability to work with different materials directly affects whether the finished product feels smooth and consistent.

PVC is a common base material for mid- and high-end poker cards because of its moderate flexibility and controllable price. However, the edges of this material are easily stretched and deformed during the die-cutting process, which is the reason why the edges of playing cards are rough and feel astringent. The transparent card die-cutting machine adopts visual correction and positioning technology to find the position error of PVC material in real time. The correction time is less than 50 milliseconds. The single-step feeding error is within ±0.03 mm, which is due to the stepping precision feeding mechanism. This can avoid the internal stress caused by the material being pulled during the conveying process and ensure the flatness of the edge after die-cutting. The equipment can also be used for different types of materials, such as paper, film, and soft magnetic sheets. The 7.5 kW servo stamping power output curve is changed to adapt to the flexibility of PVC. The progressive pressure application method is adopted to avoid the edge burrs generated when the material is impacted by a large force at one time. This makes the edges of the PVC poker cards smooth and non-sticky.

PET material has high hardness and good transparency and is a good material for making high-grade transparent playing cards. However, the resistivity of the material is as high as 10¹⁶~10¹⁸ Ω·cm, which is prone to static electricity during cutting, and the edges are prone to chipping. The feeding mechanism of the transparent card die-cutting machine is optimized for friction, and the silicone anti-skid roller is used in conjunction with the stepping feeding. This not only ensures the stability of the PET material during the transmission process but also reduces the static electricity generated by friction. Due to the high hardness of PET material, the equipment does not need to use nail holes or continuous point fixing. Through precise die-cutting track control, the material can be formed without additional support, avoiding the tactile problem caused by nail hole residue. Actual production data show that this process can reduce the edge chipping rate of PET playing cards to less than 0.1%, making the edges of playing cards more rounded.

High-end plastic cards, such as PC and ABS composites, are often used to make custom playing cards. These materials require high precision and surface integrity when die-cutting. The transparent card die-cutting machine can make the finished product accuracy reach ±0.05 mm. It also has the advantage of fast replacement of wooden light molds (replacement time is only 2-3 minutes). The die-cutting scheme can also be quickly replaced to adapt to the hardness and toughness of different high-end plastics. It is very suitable for small batch production of high-end poker and proofing. The mold adopts high-precision engraving technology and a stable servo power system, and the punching is accurate. It avoids scratches and delamination on the edge or surface of high-end plastics due to the stress concentration of die cutting and retains the delicate touch of the material.

The "washing edge" effect of playing cards, that is, the consistency of the edge chamfer, is an important part of the shuffling feel. The traditional die-cutting equipment has unstable pressure and inaccurate feeding, which can easily cause problems such as uneven chamfering depth and residual edge burrs. In this way, card jamming and uneven feel are prone to occur when shuffling. The transparent card die-cutting machine adopts high-pressure precision machining technology and a multi-dimensional precision control mechanism to make the chamfering standard of playing cards perfect.

The most important thing in high-pressure precision machining is to control the 7.5 KW servo stamping power just right. The machine can automatically change the punching pressure according to the thickness of the poker material (normal range is 0.2-0.5 mm). The pressure adjustment accuracy is ±0.01 MPa, ensuring that each card is subjected to the same force. The cards are always kept in the same position during the die-cutting process due to the step-by-step precision feeding. This ensures that the chamfer does not shift. The die-cutting precision of the machine is 40% higher than that of the traditional flat-bed die-cutting machine. The chamfering size error can be controlled within ±0.02 mm, which means that the edges of the playing cards will have a smooth sliding touch when shuffling.

Only after deburring can the "edge cleaning" effect be achieved. The clean card die-cutting machine makes the contact angle between the die-cutting knife and the material reach the best. At the same time, the tungsten steel die is used for high-pressure punching, and the material is separated at the moment of punching so that the edge fiber is not stretched or torn. The equipment also has an automatic waste removal system, which can immediately remove the edge waste after die cutting. This prevents waste from sticking to the edges of the cards and affecting the feel. The equipment can accurately chamfer small batch orders without complicated machine adjustment. When switching orders, the machine can complete the adjustment in only 15 minutes, taking into account the flexibility of production and the stability of the process. Actual measurement data from a printing company shows that the detection rate of burrs on the edges of playing cards produced by the equipment is 0, and the shuffling smoothness is 35% higher than that of the old process.

The chamfering process of the transparent card die-cutting machine can also be replaced to meet the design needs of different playing cards. The chamfering arc can be changed by replacing the wooden die, usually between 0.3 and 0.8 mm. Mass production, no matter what shape the chamfer or rounded corner of the playing card is, can maintain the quality. This flexibility is not only applicable to the production of playing cards but also to the chamfering of products such as smart cards, animation cards, and bank cards. It is a complete die-cutting solution for the printing industry.

Static electricity is generated when PET, PVC, and other transparent plastic materials are die-cut, which is a hidden danger to the feel and quality of playing cards. Static electricity not only causes the cards to absorb dust and waste, making the cards dirty, but also causes the cards to stick together, making it more difficult to collect the finished products and process them later. In extreme cases, electrostatic discharge can even damage the printed pattern on the card. The transparent card die-cutting machine adopts multiple electrostatic control technologies, which solves this problem in the industry from the source. This keeps the playing cards clean and gives them a consistent feel.

The equipment adopts an all-round grounding design. The metal parts, such as the die-cutting knife, paper feeding roller, and paper collecting mechanism, are all grounded through low resistance (≤1Ω) wires to form a complete electrostatic discharge channel. This can quickly conduct away the static charge generated during the die-cutting process. In addition, as transparent plastic is a good insulator, the equipment also has an ambient humidity control module, which can stabilize the humidity of the processing area at 40% to 60% RH. This humidity can reduce the electrostatic voltage by 30% to 50%, thereby preventing the accumulation of charge. Actual measurement data show that the regulation mechanism can keep the surface electrostatic voltage in the die-cutting process of PET playing cards below 50V. Far below the industry safety limit of 200V.

The transparent card die-cutting machine not only prevents and controls static electricity from the source but also reduces the amount of static electricity generated through process optimization. The feeding mechanism adopts silicone rollers with a low friction coefficient. The smooth step-by-step feeding reduces the friction frequency and intensity between the material and the equipment components and also reduces the amount of static electricity generated from the source. The equipment is matched with high-end plastic cards and substrates treated with antistatic coating, such as carbon nanotube antistatic PET materials. The surface resistivity of these materials can be stabilized at 10⁵ Ω, which can prevent static electricity accumulation without changing the appearance and feel of the card.

The combination of electrostatic control technology and automatic collection system makes the playing of poker more exciting. The device can collect in two ways: in sequence or by type. During collection, an ionizing air bar eliminates any residual static electricity. This prevents the cards from sticking together or scratching the surface. This combination of technologies can reduce the card contamination rate to less than 0.2% when making small batch orders. It can also greatly improve the finished product qualification rate and tactile experience. It is especially suitable for making high-end poker cards and animation cards with very clean surface requirements.

The transparent card die-cutting machine is characterized by "short, flat, and fast," which makes it very suitable for the printing industry to produce small and large batches of cards. It also meets the strict standards for touch and precision of products such as playing cards. Its main strength is that it covers the entire production process, making it a complete solution from handling materials to packaging finished products.

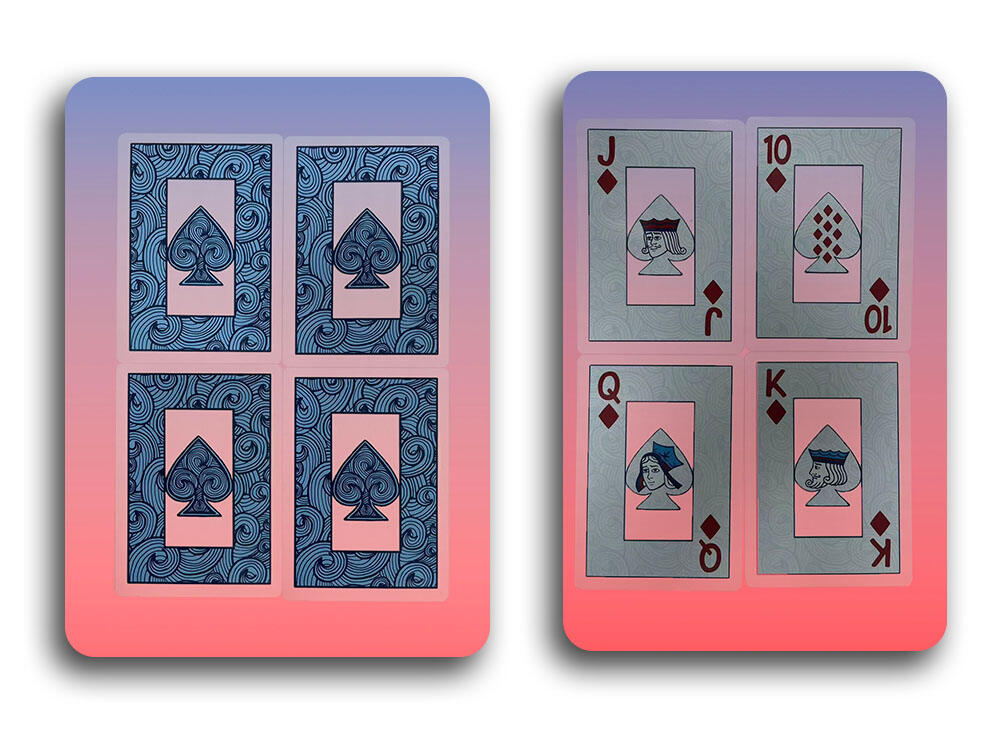

The equipment order switching adjustment time is only 15 minutes, and the mold changing time of the wooden light mold is 2-3 minutes. The efficiency is more than 60% higher than that of traditional die-cutting equipment, which can quickly meet the needs of proofing and production of playing cards of different materials and specifications. The layout stepping precision feeding and visual correction positioning technology make it not only suitable for card products but also for die-cutting of small packaging boxes, expanding the business scope of printing enterprises.

The finished product processing capacity further guarantees the touch experience. The 7.5 kW servo punching and cutting power is stable, and no nail holes or connection points are left in the die-cutting process. The edges of the poker cards are clean and delicate, leaving no traces. The automatic waste cleaning system can clean the die-cutting waste in real time so that the waste will no longer pollute the finished product. Two automatic collection methods can be switched according to production needs. Sequential collection is suitable for batch packaging, and classified collection is suitable for simultaneous production of multiple specifications. The back-end online packaging solution automates the entire process from die-cutting to packaging, reducing the tactile defects caused by manual operation.

As the product is produced in Shenzhen, China, and is aimed at the global overseas market, its design meets the technical and production needs of the international printing industry. It is also compatible with voltage and material standards in different regions. People all over the world use it to make playing cards, bank cards, smart cards, etc. The equipment consumes very little energy, which is conducive to environmental protection and meets the needs of other countries' markets. Compared with the traditional hydraulic die-cutting machine, the 7.5 kW servo power system saves 25% of energy. The power consumption per unit output is ≤0.12 kWh/thousand sheets, which reduces the production cost of printing enterprises and makes their products more competitive in the market.

The transparent card die-cutting machine adopts the combination of material adaptability optimization, high-pressure precision chamfering, and multiple electrostatic control technologies to make the playing cards feel better. Its technical features perfectly meet the needs of the printing industry, especially for small-batch, high-precision orders. Actual test data show that the burr rate of the poker cards made by the machine is 0, the chamfer size error is ≤±0.02 mm, the dirty card rate caused by static electricity is ≤0.2%, and the shuffling smoothness is 35% higher than that of the traditional process. The adjustment and mold-changing efficiency of the machine is more than 60% higher than that of traditional equipment, the production cycle of small batch orders is shortened by 40%, and the energy consumption is reduced by 25%.

These figures show that the transparent card die-cutting machine is very important for improving the feel of the product, improving production efficiency, and reducing costs. Not only can it produce playing cards with ease, but it can also easily meet the processing needs of products such as smart cards, animation cards, bank cards, and small packaging boxes. Provide efficient, accurate, and flexible die-cutting technology support for the global printing industry. As the printing industry has higher and higher requirements for the touch and quality of products, the transparent card die-cutting machine will become the most important tool for making high-end cards. This will lead to better technology and higher product value.