The number of small-batch card orders in the market is increasing every year, including customized membership cards, independent game card manufacturers, and cultural and creative theme cards. These orders mainly have three requirements: fast turnaround, cost-effectiveness, and consistent quality.

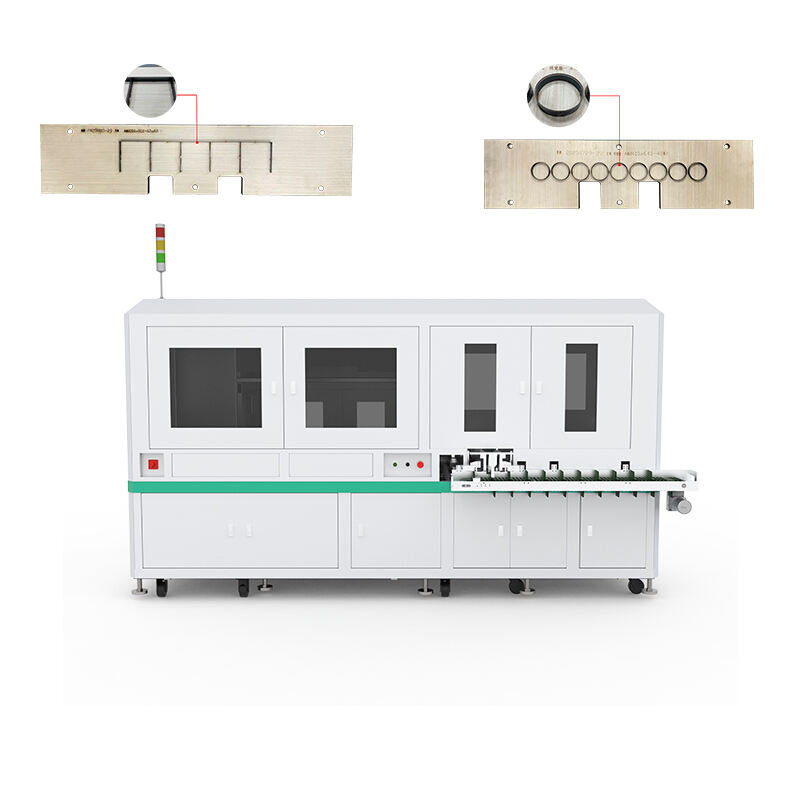

As a professional customized card production equipment manufacturer located in Shenzhen, China, we understand the needs of overseas customers. Our newly designed step-by-step feeding die-cutting machine brings the efficiency of "short, flat, and fast" to die-cutting. It can process cards made of paper, wood, plastic, and other materials. At the same time, the equipment also has automatic classification and sorting functions, which meet the needs of small batch production of diversified cards.

Small-batch card orders, such as 500 to 5,000 customized membership cards, independent game cards, and various cultural and creative theme cards, have been increasing year by year. The key value proposition of these orders is "fast delivery, controllable cost, and predictable quality."

Traditional card-making machines require 2-3 hours of debugging time to set up various molds and production parameters. The "debugging cost is higher than the production cost" when producing in small batches.

In order to improve efficiency, the machine needs to be started for mass continuous production. Small-batch orders are prone to cause time cost waste of "start-up and shutdown."

Manual sorting is cumbersome and prone to errors. Sorting alone can only be done at a rate of about 1,000 pieces per hour by one person.

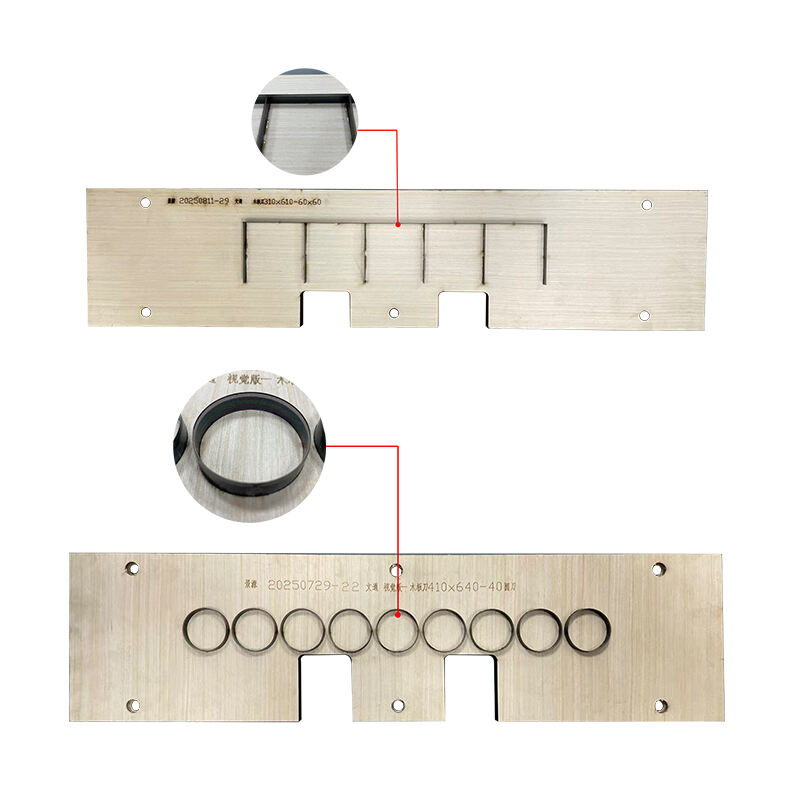

In terms of speed, the wooden and lightweight mold can realize rapid mold change. The standard card sizes, such as the 8654 mm membership card and the 6090 mm game card, are stored and can be called with one key, and the debugging time is shortened to 15 minutes.

Small order production: starting from 500 sheets per batch, the system can run below full load, and no additional fees will be charged for batch switching.

Integrated automated sorting: automated docking of counters, directly solving the problem of high labor costs abroad

One of the competitive advantages of the distributed feeding die-cutting machine is its strong adaptability to 'mainstream overseas card types' and 'various production materials.' There is no need to replace the core components to meet a variety of needs.

Game cards: including trading card game (TCG) cards, board game cards, and children's puzzle cards. The device can be adjusted to the surface of the card with hot stamping and embossing texture details. The pattern is completely die-cut, with no burrs, and the cut is maintained.

Membership card: divided into chip card, magnetic stripe card, and barcode membership card. It can be cut into the shape of an ellipse, square, rounded rectangle, etc. specified by the target overseas market.

Smart cards: IC cards, NFC smart cards, and RFID cards automatically avoid the chip area when die-cutting. and smart cards with damaged electronic components are generated under the Internet of Things and consumer-oriented applications."

Paper cards: copperplate paper game cards, cardboard membership cards. The flexible feeding system is adopted to avoid problems such as paper jams and material wrinkling. The edge is smooth and burr-free after die cutting.

Wooden cards: solid wood, density board, commemorative cards. The characteristic of wood is that it is easy to crack. Through low-speed stepping feeding, the material stress is reduced, and the yield of stepping feeding is as high as 99.8%.

Plastic cards: including PVC membership cards, PET game cards, and PP smart card substrates. Adapt to the hardness of different plastic materials, ensure no sticking and no warping after die cutting, and pass the overseas quality.

When we choose equipment, we mainly consider three aspects: "efficiency, quality, and cost." The step-by-step feeding die-cutting machine solves these three problems through three major advantages.

Short cycle: 5,000 plastic membership cards can be completed in 2 hours from start to finish. This is 40% more efficient than traditional equipment.

Heisei edition: Because small-batch production does not require the amortization of high debugging costs, the cost of single-sheet die-cutting is 15%-20% cheaper than traditional equipment, making the cost feasible. Quick response: Supports temporary adjustments by overseas customers. Changes to card specifications (such as rounded corners becoming right angles) can be completed within 10 minutes to meet urgent modification needs.

The problem of continuous points (i.e., the edge is not cut through, and multiple sheets are stuck together) is more common in small batch production, which affects customer acceptance. For the step-by-step feeding die-cutting machine, the "servo motor precise positioning + step-by-step feeding technology" is adopted, and the feeding error is controlled within ±0.1 mm. In addition, the die-cutting force is uniform, ensuring that each edge is completely cut off without any connection points or burrs. Meet the stringent quality requirements of overseas markets such as Europe, America, and Southeast Asia.

The cost of labor is high, and the small batch production and sorting links need 2-3 people, and the efficiency is getting lower and lower. The intelligent sorting module integrated in one of our devices can automatically classify cards according to size, color, or even QR code/barcode. The sorting accuracy rate is 99.9%, and more than 3,000 cards can be processed per hour. Manual sorting requirements are reduced by 80%.

Shenzhen equipment manufacturers like us make full use of the advantages of Shenzhen's global intelligent manufacturing center supply chain to provide full-chain support for overseas customers:

Core component guarantee: In terms of component guarantee, we adopt international brand servo motors and sorting sensors. The failure rate of continuous operation equipment is at least 0.5% to ensure the reliability of the equipment.

Global standard adaptation: In terms of standard adaptation, we support 110V and 220V standards in North America, Japan, and Europe/Southeast Asia and have overseas CE and UL certifications, which are compliant with the global market.

Multi-language operation: In terms of language, the operation interface supports eight mainstream languages, including English, Spanish, German, and Japanese, which is convenient for overseas employees to quickly understand.

After-sales service and logistics: After-sales service points are set up in Europe, America, Southeast Asia, the Middle East, and other places, and the fault demand is responded to within 48 hours. We cooperate with DHL and FedEx to deliver goods from the Shenzhen factory to overseas customers' factories within 7-15 days.