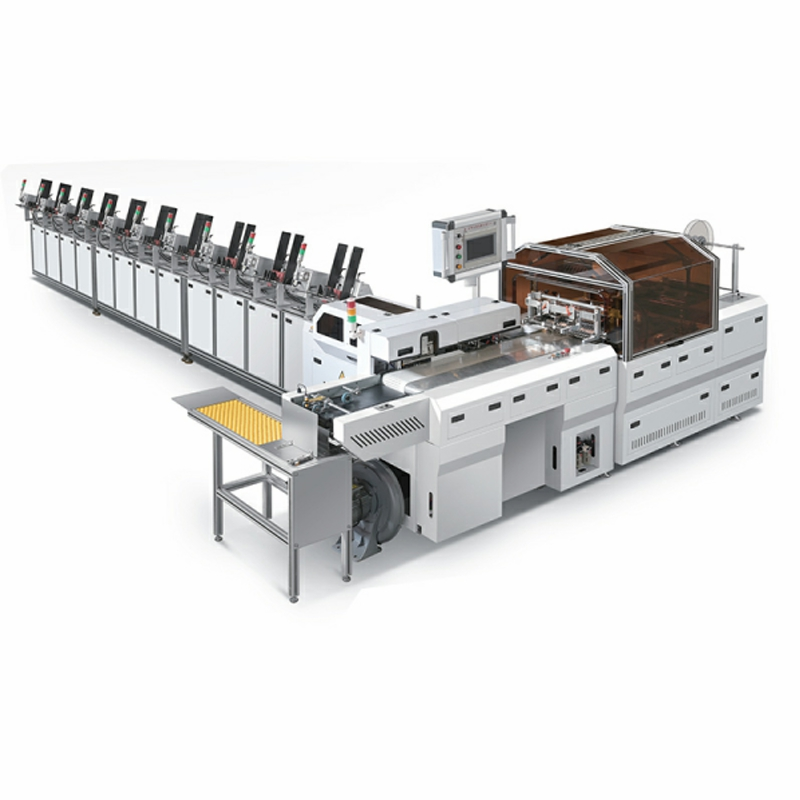

For every card-making business, our card slitting machines form an integral part of the system. These machines are constructed from high-grade parts which guarantee performance for a long time. The cutting system is designed to eliminate vibrations, thus ensuring cuts are neat and precise. The equipment can manage large scale production runs as well as small custom order. Different blades can be selected depending on the type of card material in order to achieve different cutting results. The machine can be set up easily which makes it a delight to work with due to the robust controls; simple and fast adjustments yield professional looking cards.