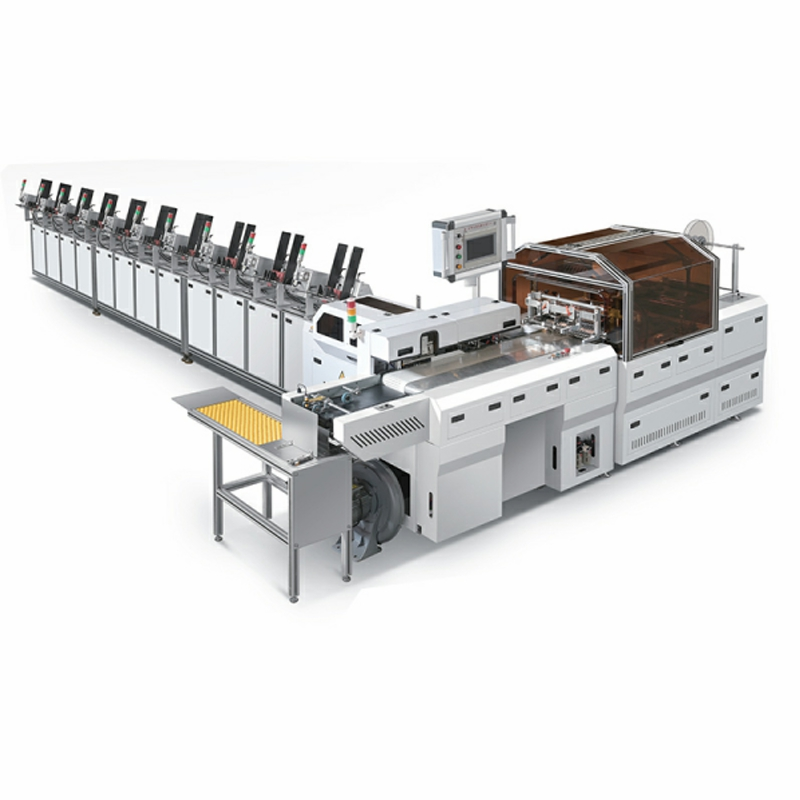

In the card manufacturing industry, accuracy and slitting efficiency are very critical. Our state-of-the-art slitting machines are equipped with high-quality, long-lasting blades capable of cutting card materials like PVC, paper, and plastic. They make precise cuts with different types of production conditions whether it’s for playing cards, business cards or SIM cards. The automation of the features of the machines help enhance productivity while lessening the need for manual labor. The settings of the cuts can easily be adjusted making it easier to obtain the preferred size and shape of the cuts. With our top-of-the-line slitting machines, production of high-quality cards can be made on time which lowers the production cost while increasing customer satisfaction.