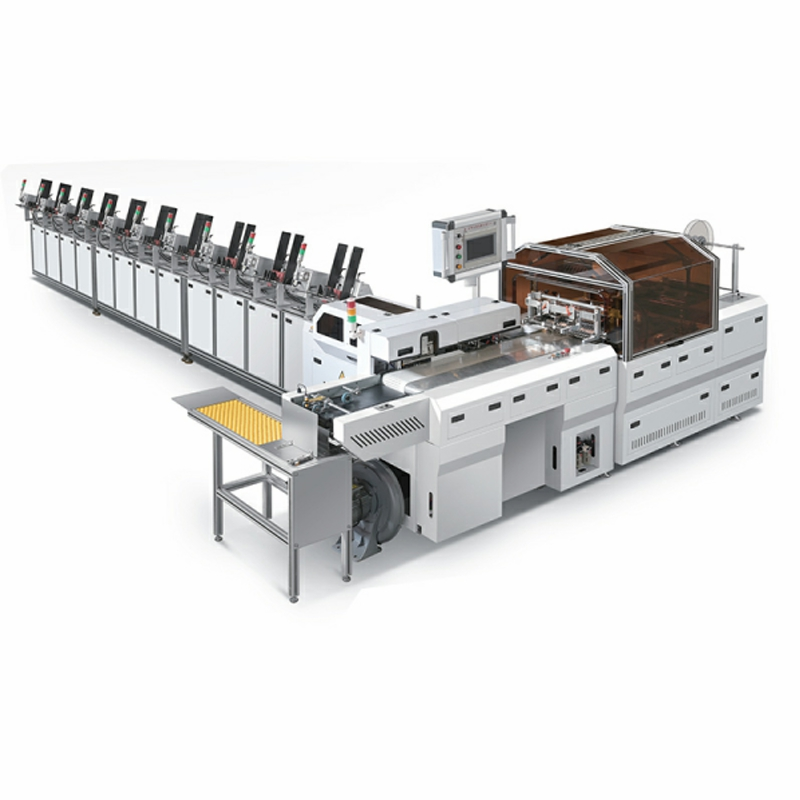

Advanced Control Technology

Our slitting machines come equipped with modern control systems and touch screen user interfaces. With the intelligent control panels, operators can conveniently set parameters, track the cutting action as it happens, and make adjustments in real time and control adjustments as needed. Also, intelligent algorithms optimize the automated cutting of the machine relative to the material characteristics and production requirements. This know-how is efficiency and precision cutting, simplicity of operation, reduced operational learning time, and wide-ranging applicability for accessible for all operators regardless of business size.