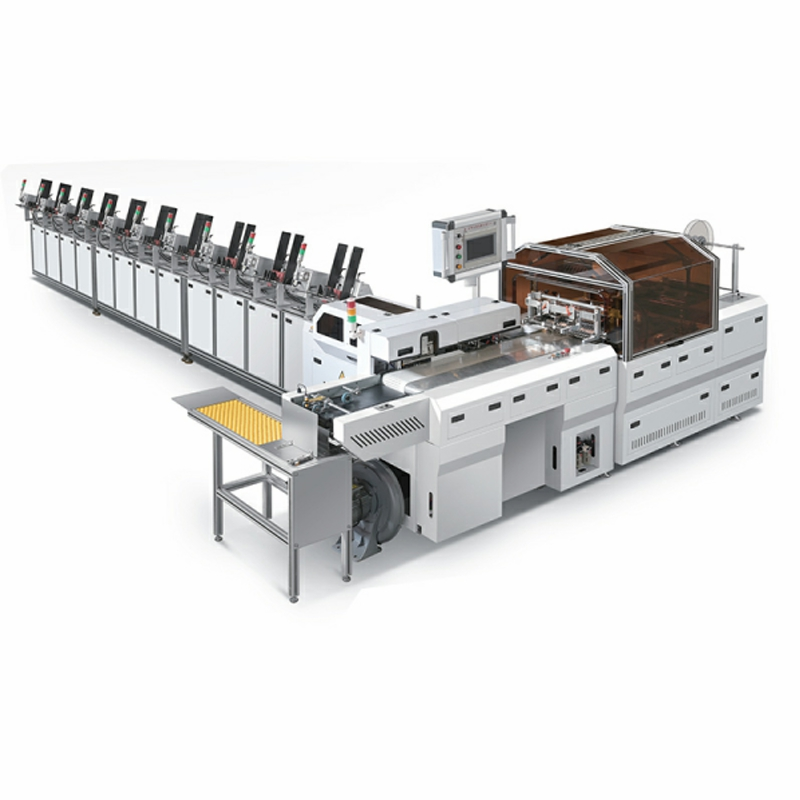

Flexible and Adjustable to Various Materials

The adaptability of our slitting machines stands out as one of it’s primary advantages. Whether the material is thin films or fragile papers, as well as thick sheets of fabric and even heavy duty industrial goods, our machines will accommodate for the wide variety of materials. Settings for blade pressure, cutting speed, and tension control are all adjustable, which allows for customization to different material properties. This level of flexibility makes them suitable for use in a multitude of sectors such as packaging, printing, textiles, and many others. Regardless of how specific your material - slitting requirements are, our machines will present a dependable and efficient answer.