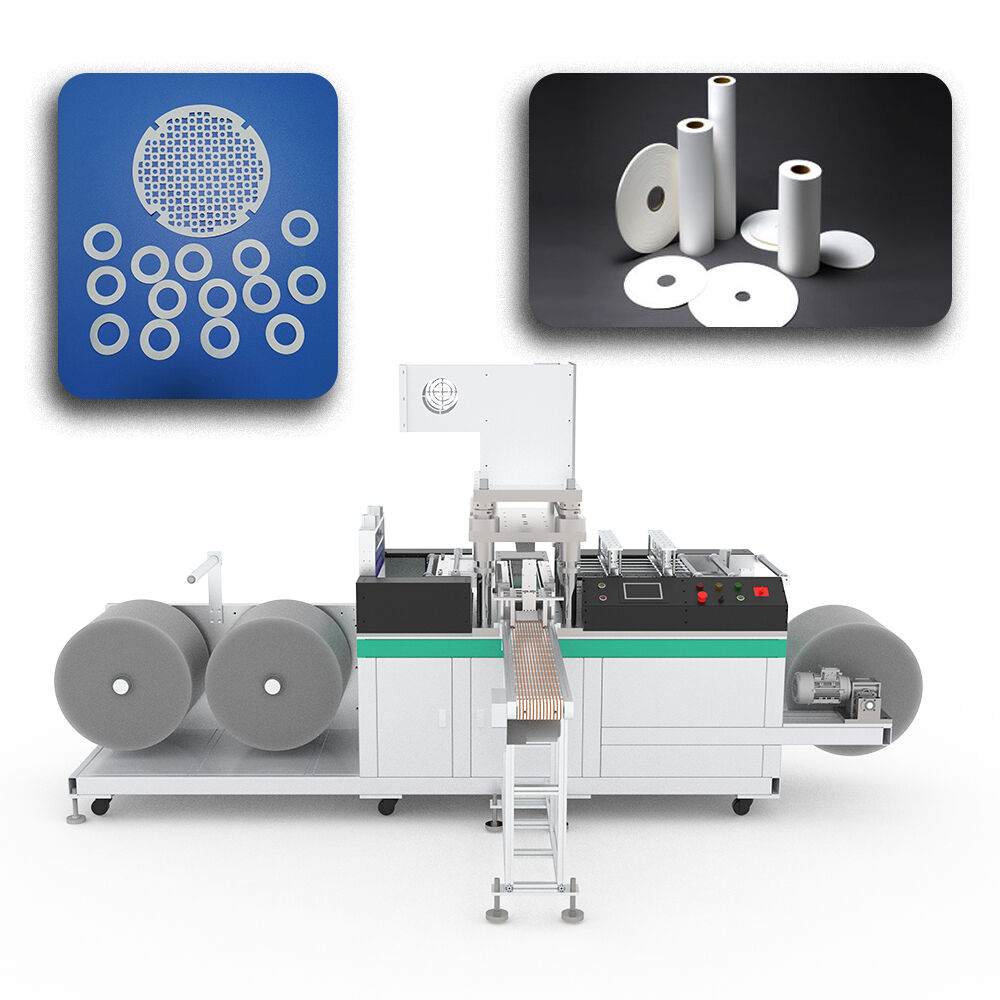

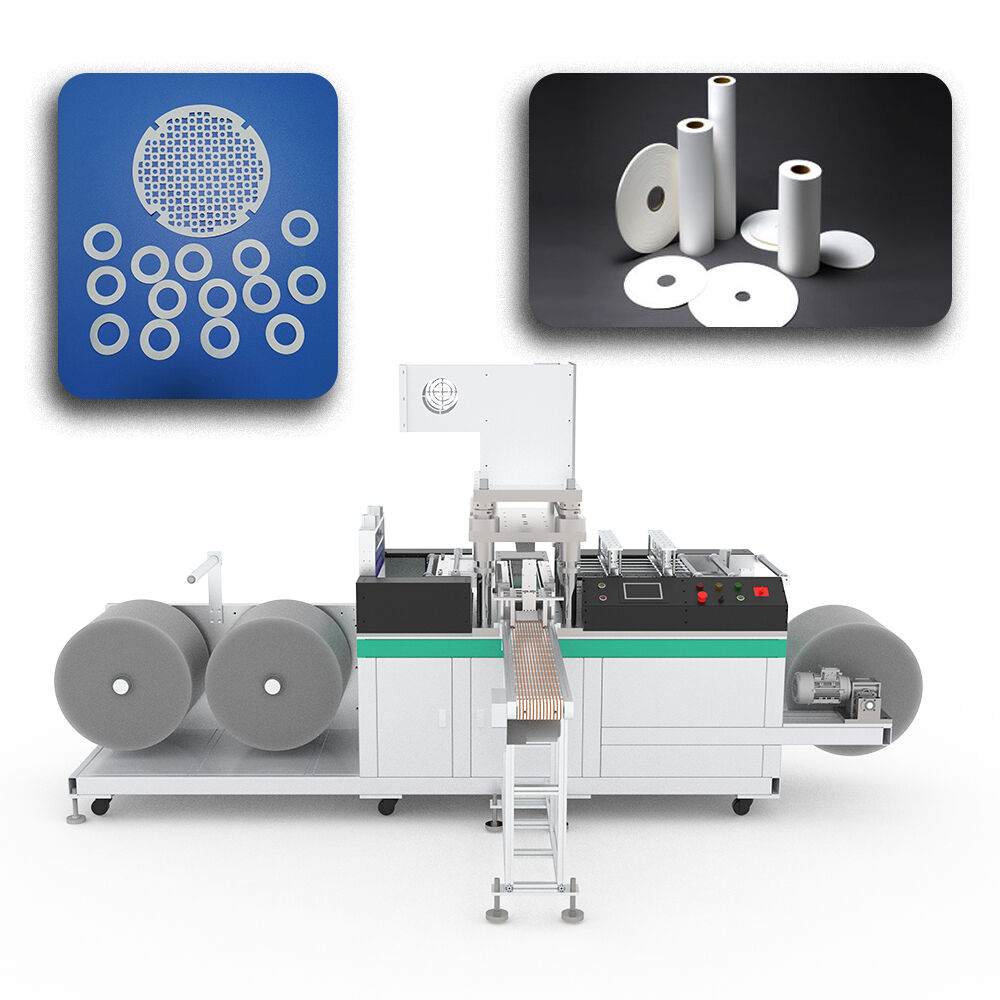

In the field of high-end manufacturing and processing of special materials, the level of specialization, automation, and intelligence of equipment is the most important factor affecting product quality, production efficiency, and market competitiveness. The traditional production methods of silicone oil paper, filter ring paper, filter paper, filter paper rings, filter paper cores, steamer paper, coated paper, non-stick oil paper pads, and other products can no longer meet the needs of modern industry for precision, cleanliness, and large-scale automated production. The filter paper die-cutting machine is the best way to solve this problem. Not only does one machine complete the "punching" work, but it is also an automated production unit that integrates high-precision mechanical engineering, intelligent sensing control, and flexible production logic. Its goal is to turn coil or sheet material into high-quality finished products that have been sorted and are ready for packaging or assembly.

1. The core product production system of the die-cutting machine

The people who made this machine had a deep understanding of the final product when they designed it. It produces a wide range of products, from industrial core components to daily necessities, each of which has strict requirements for processing technology.

High-precision industrial filter elements: the key to ensuring the good operation of the filtration system

-

Filter paper ring: It is the main sealing or filtering layer of various oil filters, air filters, and water filters. The precision of its inner diameter, outer diameter, and concentricity directly affect the sealing and filtering uniformity of the filter. The punching accuracy of the machine can reach ±0.15 mm, which ensures the consistent size of each ring filter paper and no fiber burrs on the edge and solves the problem of media bypass or assembly.

-

Filter paper core and structural paper ring: The filter paper core and structural paper ring constitute the skeleton or support layer of the filter element. The equipment can process thick, multi-layer composite filter paper and continuously and accurately cut out complex shapes (such as wavy and toothed shapes) to form a three-dimensional structure with specific flow channels and supporting strength. This is something that traditional manual or laser cutting cannot efficiently complete.

-

Special-shaped filter paper: Special-shaped filter paper is used for disposable filter bags, plate and frame filters, etc. Through customized stamping, different non-standard geometric shapes can be made to meet the needs of special filtration equipment.

Food-grade safety paper: a good example of meeting hygiene and efficiency standards

-

Silicone oil paper (non-stick oil baking mat) and steamer paper: Because they are in direct contact with food, they must be completely clean and free of any pollutants. The equipment adopts food-grade materials and surface treatment to ensure that there is no oil contact. The stamping process does not leave dust and debris, the incision is smooth, and the edge fibers will not fall off during baking or steaming, damaging the food. Different shapes of gaskets, such as round, square, and custom shapes, can be quickly made to meet the needs of the catering industry.

-

PE-coated paper, non-stick oil paper pad: When punching and cutting this kind of paper, the PE, silicone oil, and other coatings are easy to separate from the paper base (edge dropping) due to the stress. The machine achieves a perfect "clean cut" by controlling the angle, temperature, and pressure curve of the cutter. The coating and paper base are well combined, and the incision is neat.

Multifunctional expansion applications: Maximize the value of your equipment investment

-

Card cutting function: By changing the platform and mold, the equipment can be quickly transformed into a high-precision flat-bed die-cutting machine. The machine is used for smart cards, game cards, recharge cards, etc. It can do many things at one time, which makes it more useful, especially for processing companies that get many different types of orders.

-

Special industrial gaskets: Special industrial gaskets such as insulation and sealing paper gaskets used on generators and other machines require high precision and cannot have burrs.

2. Main function inspection: the transformation from "processing link" to "finished product output terminal"

The most important thing about the filter paper die-cutting machine is that it has changed the production method, and many separate post-processing steps that need to be completed manually are combined into one machine to complete at one time.

Quality empowerment: Equipment is the "gatekeeper" for maintaining product quality consistency. With the advanced rigid structure and 7.5 kW high-response servo drive system, it provides continuous and stable high-tonnage pressure and millimeter-level positioning accuracy. This eliminates the uncertainty of manual operation and ensures accurate punching without burrs. This means that filtration products will always work in the same way, and food packaging will always be safe and look good.

Efficiency revolution: The equipment compresses the production process into a straight line, making production more efficient. The most prominent feature is its automatic sorting function. The equipment can distinguish different products in real time during continuous stamping through the built-in high-resolution vision system or mechanical encoder. For example, it can distinguish filter ring paper and gaskets of different diameters and divert them to different flow directions. The collection, sorting, and classification work used to require at least two or three people to complete. Production efficiency has increased by more than 200%, achieving "zero misjudgment."

Management optimization: The equipment provides you with a complete customized solution. From automatic tension control of raw material rolls to die cutting, sorting, and finally customized finished product collection methods (① collection in order for kit assembly; ② collection by category for independent packaging of mixed products), a closed and efficient micro production line is formed. This makes production management easier, reduces work-in-process inventory and handling, and achieves lean production.

The following ten carefully designed technical features support these three main functions:

-

Durability and long-term stability beyond the standard: The frame is designed with finite element analysis (FEA) and is more durable and stable over time than standard frames. Made of high-strength ductile iron or steel plate welding, after multiple stress relief treatments, the deformation resistance is extremely strong. The guide rails and bearings that make up the core sliding parts are all from top international brands. The design life is at least 60,000 hours. The equipment's mean time between failures (MTBF) is far above the industry average. It is designed to operate in harsh environments, with production uptime of 24 hours a day, seven days a week.

-

High production flexibility with one machine for multiple uses: The equipment has a modular quick-change system, which makes it very flexible in use. The die-cutting table is compatible with many different standards, and it only takes 30 minutes to replace all the dies. Switching from producing filter paper cores to cutting baking silicone paper only requires changing the mold and calling the preset program. This enables small-batch, multi-variety orders to be completed quickly, reducing the cost and time of increasing production for enterprises.

-

Integrated online hot stamping printing unit (optional): The equipment can be easily connected to the CNC hot stamping or cold stamping unit to meet the needs of brand identification and product beautification. During die-cutting, the logo, pattern, or text can be accurately placed in the required position and hot stamped on materials such as copperplate paper and non-stick oil paper pads. The value of the product is greatly improved by completing the process from material to finished product in one step.

-

Power core: 7.5 kW full closed-loop servo drive system. The servo system can be steplessly speed-regulated, instantly responsive, and accurately powered, which is better than the traditional pneumatic or ordinary motor drive. Its position control accuracy is ±0.02 mm, and its repeated positioning accuracy is ±0.01 mm. It saves 25% to 40% of energy, and the running noise is less than 75 decibels, making the production environment quiet. This is the most important factor to ensure high speed (stamping frequency up to 200 times per minute) and high precision.

-

Intelligent finished product collection and logistics docking system: the collection method can be changed according to the production method. The negative pressure adsorption type is used for the sequential stacking of light and thin distillation paper that is easy to float. For filter paper rings with certain rigidity, the guide groove is used for classification and collection. It can be directly connected to the feed inlet of the automatic packaging machine or the turnover box to realize the full automation of the production end.

-

Engineering realization of burr-free precision stamping: burrs are caused by tool wear, improper clearance, or unstable pressure. The equipment adopts special alloy steel material for the mold and has an automatic compensation system for the mold gap, which can adjust the mold gap to the micron level. It also has a punching curve that changes according to the material characteristics. This ensures that the blade cuts into the material at the optimum angle and pressure. Even when cutting 8-10 layers of composite filter paper, the cut surface can remain smooth under the microscope.

-

Solid structure and industrial aesthetic design: the equipment cover is made of high-quality cold-rolled steel plate and automotive baking paint process. It is not only rust-proof and wear-resistant but also gives the high-end equipment a unique texture and professional trust. The humanized HMI is reasonably arranged, and the fault diagnosis information is presented in a way that is easier for operators to learn.

-

Mature control system based on big data iteration: The control system kernel has been trained and iterated by thousands of devices in the field for several years. It also pre-stores processing parameter models for dozens of common materials. Users only need to call the appropriate model to quickly obtain the processing effect close to the best. This saves a lot of time and money on trial runs and debugging.

- Deeply customized "turnkey" engineering capabilities, including demand analysis, scheme design, mold development, equipment manufacturing, installation and debugging, personnel training, etc. We can provide targeted engineering design and integration services for special needs such as ultra-wide (up to 1600 mm) raw materials or the need to connect with upstream coating lines and downstream packaging lines.

-

Automated sorting and distribution: This system is the "eyes" and "brain" of the machine. It uses industrial-grade CCD cameras and special image processing algorithms to reliably identify the shape, color, or hole position of products moving at high speed. The sorting actuator accurately moves the product into the correct channel through air blowing, push rods, belt steering, and other methods, and the sorting accuracy rate is more than 99.9%.

4. Target customer base and global service network

This equipment is the perfect choice for companies around the world that want to improve quality and efficiency:

-

Automotive/Industrial Filter Manufacturers: Automotive and industrial filter manufacturers need to produce a large number of different filter papers, filter rings, and filter paper cores, all of which are highly consistent.

-

Food packaging and baking supplies manufacturer: A food packaging and baking supplies company that only makes silicone oil paper, steamer paper, and non-stick oil paper pads and has very strict requirements for cleanliness, efficiency, and appearance.

-

Special paper processing and trading company: Undertake all kinds of special-shaped and difficult die-cutting orders. The equipment needs to be very flexible and reliable.

- Medical and laboratory consumables manufacturers produce products such as diagnostic test strips and filter membranes, which must be very precise and dust-free.

-

Environmental Equipment & Water Treatment Co.: Environmental Equipment & Water Treatment Co. manufactures its own filter elements.

We are located in Shenzhen, China, the world's hardware innovation center. We have the best supply chain advantages and the fastest R&D capabilities. We not only export equipment but also export knowledge of mature production processes. To ensure that customers in Europe, the United States, Southeast Asia, and other regions can obtain technical support within 24 hours and provide engineers to provide on-site services as needed, we have established localized service and spare parts centers in these regions. This puts overseas customers completely at ease.

Overall, this filter paper die-cutting machine sets a new standard for productivity. It combines precision mechanical engineering, intelligent control logic, and a deep understanding of industry processes to provide customers with a comprehensive answer to the question of "how to professionally produce special paper products." It is not only a way to increase current production capacity but also a strategic asset for enterprises to move toward digitalization and automation in the future. Choosing it means choosing a sustainable development path based on technology and quality.